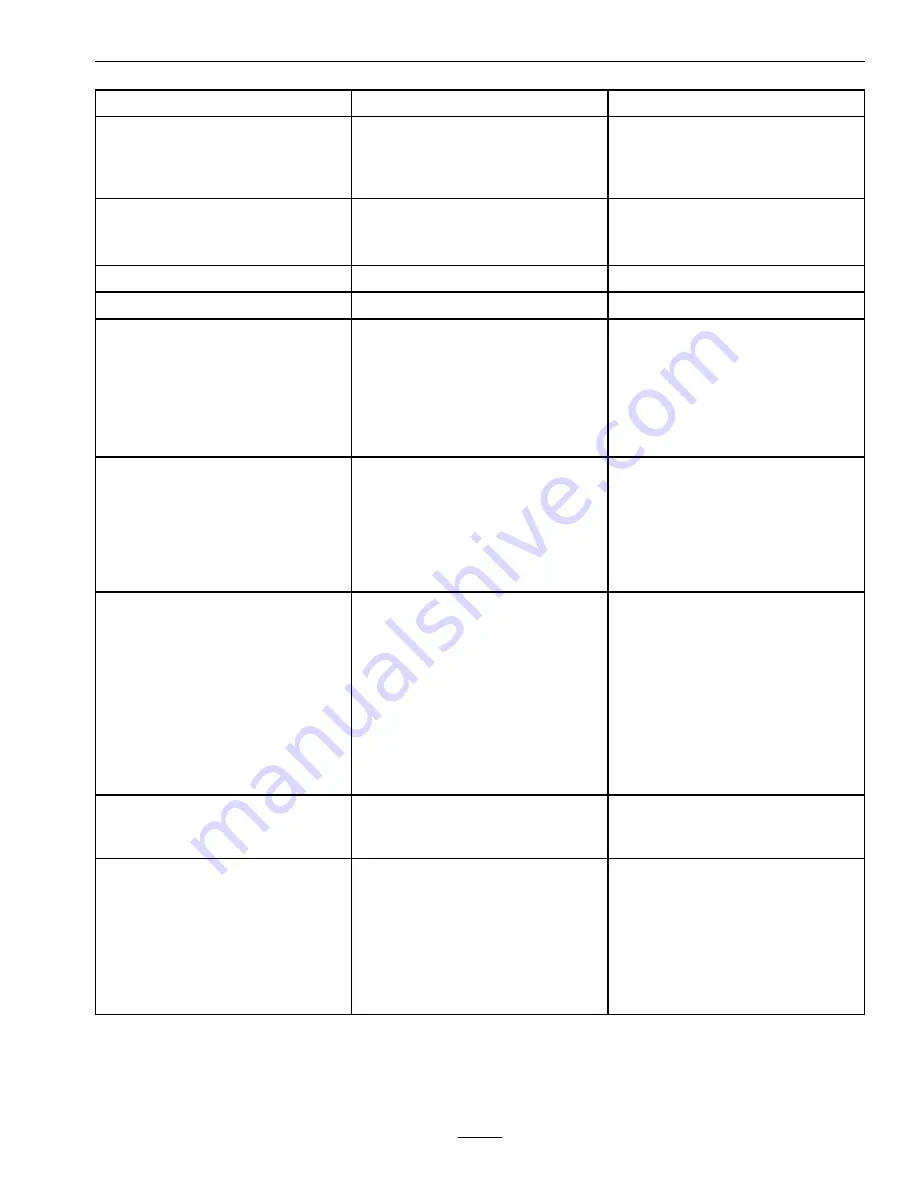

Troubleshooting

Problem

Possible Cause

Corrective Action

1. Engine load is excessive

1. Reduce the ground speed.

2. Oil level in the crankcase is low.

2. Add oil to the crankcase.

Engine overheats

3. Cooling fins and air passages for the

engine are plugged.

3. Remove the obstructions from the

cooling fins and air passages.

1. Tire pressure in drive tires not correct.

1. Adjust tire pressure in the drive tires.

2. Damaged control linkage.

2. Replace control linkage.

Machine pulls left or right (with lever fully

forward).

3. Tracking not set.

3. Adjust tracking.

Machine does not drive.

1. Bypass valve is not closed tight.

1. Tighten the bypass valve.

Abnormal vibration

1. Engine mounting bolts are loose.

1. Tighten the engine mounting bolts.

1. Debris buildup.

1. Clean impeller.

2. Hopper screen is plugged.

2. Clean hopper screen.

3. Spreader motor is loose or damaged.

3. Repair or replace motor.

4. Spreader motor hydro failure.

4. Check connections.

5. Spreader controller turned off or down.

5. Check controller knob positions.

6. Shaft pin is missing.

6. Replace shaft pin.

Impeller does not rotate.

7. Impeller motor bearing failure.

7. Replace bearing or entire motor.

1. Impeller is dirty or damaged.

1. Clean, repair, or replace impeller.

2. Gate not adjusted properly.

2. Adjust the gate. See

Spreader Pattern

Adjustment

section in Operation.

3. Nozzles are clogged.

3. Unclog or replace nozzles.

4. Hopper screen is plugged.

4. Clean hopper screen.

5. Material clumps over gate.

5. Check motor shaft agitator pin presence.

Uneven spread/spray pattern.

6. Diffuser ramp setting incorrect.

6. Adjust control cable position.

1. Tank is empty.

1. Fill tank.

2. Strainer is clogged or damaged.

2. Clean, repair, or replace strainer.

3. Pump is clogged or damaged.

3. Clean, repair, or replace pump.

4. Nozzles are clogged.

4. Unclog or replace nozzles.

5. Hoses are clogged, kinked, or damaged.

5. Clean, repair, or replace hoses.

6. Spray control not on.

6. Turn on spray.

7. Spray pressure and speed incorrect.

7. Adjust pressure and speed.

8. Spray mixture is incorrect.

8. Follow chemical manufacturer’s

recommendation.

No front spray or poor output.

9. Spray system is leaking or sucking air.

9. Inspect system and clean, repair, or

replace components as needed.

1. Hopper screen is plugged.

1. Clean hopper screen.

No material dispensed from hopper.

2. Gate not adjusted properly.

2. Adjust the gate. See

Spreader Pattern

Adjustment

section in Operation.

1. Tank is empty.

1. Fill tank.

2. Control valve in wrong position.

2. Place in “open” position.

3. Wand is clogged or damaged.

3. Clean, repair, or replace wand.

4. Nozzle is clogged.

4. Unclog or replace nozzle.

5. Trigger is not pressed.

5. Press trigger.

6. Hoses are clogged or damaged.

6. Clean, repair, or replace hoses.

7. Hose is not connected to wand

7. Reconnect hose.

Spray wand does not work.

8. Hose is kinked.

8. Unkink hose.

59