FITTING INSTRUCTIONS (cont.)

FILLING THE SYSTEM

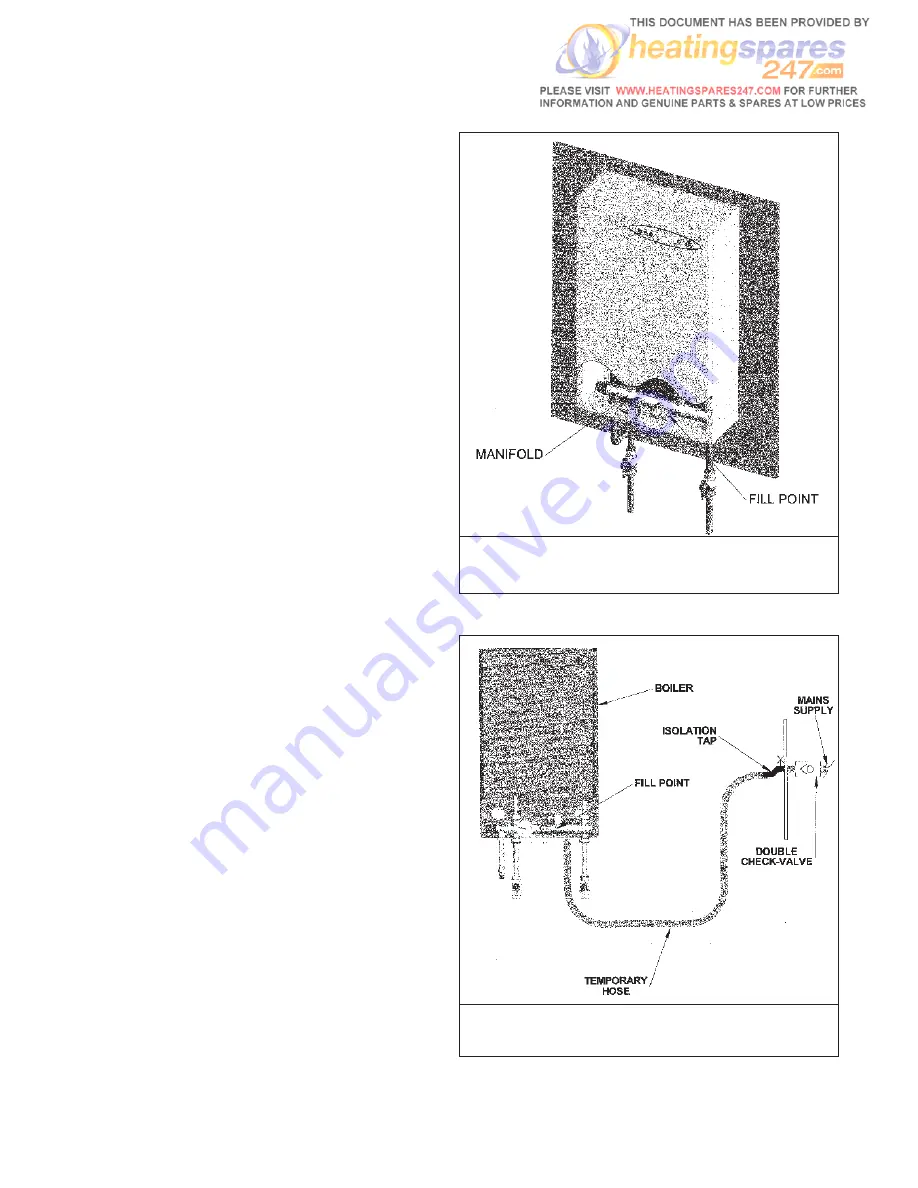

A filling point connection is provided on the front face of

the boiler manifold to facilitate the initial filling and

pressurising of the system via a hose connection

(supplied). Alternatively, a permanent filling-loop may be

employed.

Notes:

a) Before filling, ensure that all fittings and joints

have been made.

b) Thoroughly flush out the system to remove any

swarf and residue from the pipework and

radiator(s).

c) There must be no permanent connection between

the boiler and the mains water supply.

Filling Method 1: Temporary Hose (Figs. 10/11)

1) Connect a hose to the fill point on the manifold

using the fittings supplied.

2) Connect the other end of the hose to the mains

water supply, ensuring that all safety valves are

fitted in the run

(Fig. 11)

to prevent system

water entering the mains supply. Approved hose

unions should be used on all connections.

3) Open the fill point on the manifold

(Fig. 10)

by

turning the isolating knob anti-clockwise.

4) Ensure all isolation valves to the system are open,

that the bypass valve is closed, and that the

automatic air vent contained within the boiler

casings is open (turn the black cap on the device

fully anti-clockwise).

5) Switch on the mains supply to the boiler and test

the pressure relief valve by continuing to fill until

this device activates and releases water into the

drain.

6) Switch off the mains water supply.

7) Using the pressure gauge on the front face of the

manifold for reference, reduce the water content of

the system until the pressure is indicated as 1.5

bar.

8) Thoroughly vent all parts of the system of air and,

if necessary, readjust pressure back to 1.5 bar.

9) Close off the fill connection on the manifold, remove

the hose and close the automatic air vent.

10) Check all joints are water-tight before operating

the appliance.

8

FIG. 10 - FILL POINT

FIG. 11 - FILLING METHOD 1

Содержание Aztec Gold

Страница 14: ...14 FIG 17 BOILER SCHEMATIC ...