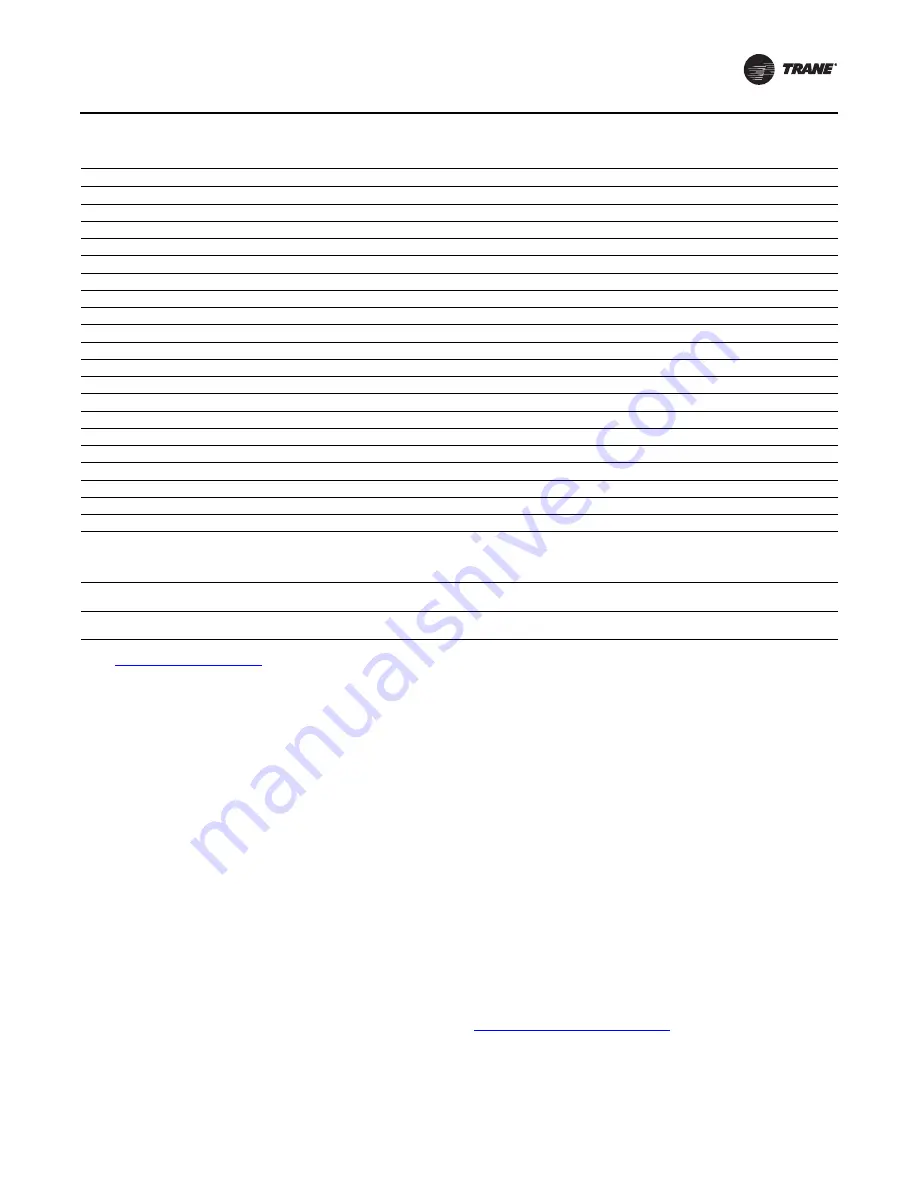

Table 23. TechView™: Configuration View: Starter Tab

Configuration of Drive

(a)

Description

Range

Default

Units

Notes

Surge Detection

0 = disable, 1 = enable

1

Surge Sensitivity

0–100

20

%

Power Loss Reset Time

0–255

60

s

Motor NP Volts (VOLT)

180–480

460

Vac

Motor NP FLA (TVA)

0–1200

0

Amps

Nameplate Data

Motor NP RLA (NMRA)

1–2000

1

Amps

Nameplate Data

Motor NP Power (CPKW)

0–1000

0

KW

Nameplate Data

Motor NP Hertz (HRTZ)

5–250

60

Hz

Nameplate Data

Motor NP RPM (TRPM)

60–24000

3600

RPM

Nameplate Data

Stator Resistance (SRES)

0–10,000,000

0

microOhms

Nameplate Data

Flux Current Ref. (FAMP)

0–1200

0

Amps

Nameplate Data

Acceleration Time

1–255

30

s

Deceleration Time

1–255

30

s

Current Limit (STCL)

1–3200

1 (1.12xNMRA)

Amps

Nameplate Data

Current Limit Gain

0–5000

10

Power Loss Mode

1 = decel

decel

Power Loss Time

0–25

0

Sec.

Flying Start Enable

0 = disable, 1 = enable

0

Enabled is not recommended

Flying Start Gain

20–32767

2000

Use Trane Defaults

No, Yes

Yes

Yes required for mst applications

No will allow ’non-Trane’ application defaults to

be utilized for all other drive parameters not

accessible via TechView

RTD Type

750 ohm @ 75°F

100 ohm @ 0°C

75 ohm

Note:

Use only above Defaults as these are the factory tested settings for this application. Instability and Faults may occur with use of other settings and

are not recommended. Contact your local Trane Representative for service when necessary.

Service Interface

AFDK-SVU01C-EN

45

Tracer AdaptiView Operator

Interface

The chiller’s Tracer AdaptiView™ display is the operator

interface for the Adjustable Frequency Drive (AFD). For the

operator’s day-to-day operational information, Tracer

AdaptiView displays data (English or SI units)

simultaneously on the 12-inch, color touch-sensitive

screen. Logically organized groups of information—chiller

modes of operation, active alarms, settings, and reports

put information conveniently at your fingertips. The AFD

status can be viewed from the Tracer AdaptiView MOTOR

target area on the home page. Refer to CTV-SVU01*-EN

(

Operations Guide: Tracer AdaptiView™ Display for

CenTraVac™ Water-cooled Chillers

) for more information

on the Tracer AdaptiView display.

Tracer TU Service Tool (Laptop Computer)

Tracer™ TU is software installed on a portable laptop

computer and used, by the service technician or advanced

operator, to interface with the UC800 or DynaView

controller on the CenTraVac™ chiller. When you need

more detailed information about a Trane

®

chiller, connect

your laptop computer (with the Tracer TU software

installed) to the UC800 or DynaView’s “Service Tool” USB

plug-in port (this port is extended to exterior of the control

panel cabinet for easy access).

Tracer TU software provides access to that particular

machine’s configuration settings, customizable limits,

status, and up to 60 active or historic alarms. Any PC that

meets the system requirements may install the most

recent release of the Tracer TU software.

Use Tracer TU when a factory or startup setting requires

field alterations. All adjustable AFD settings (see

) are available via Tracer TU. All others are set

to defaults predetermined for this application as based on

laboratory testing.

Once the new AFDK is installed, some parameters settings

may need to be changed for proper operation. Please

contact Global Parts Technical Services to request a drive

parameter sheet. The drive parameter sheet will contain a

list of chiller-specific parameter settings that may be

directly loaded using Tracer TU. To contact Global Parts

Technical Services, send a message to

. Please provide the serial

numbers for the chiller, control panel (if CH531 or Tracer

AdaptiView™ upgrade), and the AFDK when making your

request.

(a) These items must be set to the values given on the drive parameter sheet for proper operation. To request a drive parameter sheet, send a message

to

. Please provide the serial numbers for the chiller, control panel (if CH531), and the AFDK when making this request.