9

4. Assembly and

Installation

4.1 Break Point and General

Unit Assembly

Instructions

Ensure that all the air-handling unit

sections are positioned in the correct

order.

Each section will display a unit drawing

with its position OUTLINED.

1.Each of the unit sections should be

placed on a level foundation and within

200 mm of its adjoining section.

2.Remove any supports and bracing

which are supplied with the unit for

transport. All such supports will be

clearly marked:

“FOR TRANSPORT ONLY –

REMOVE BEFORE ASSEMBLY”

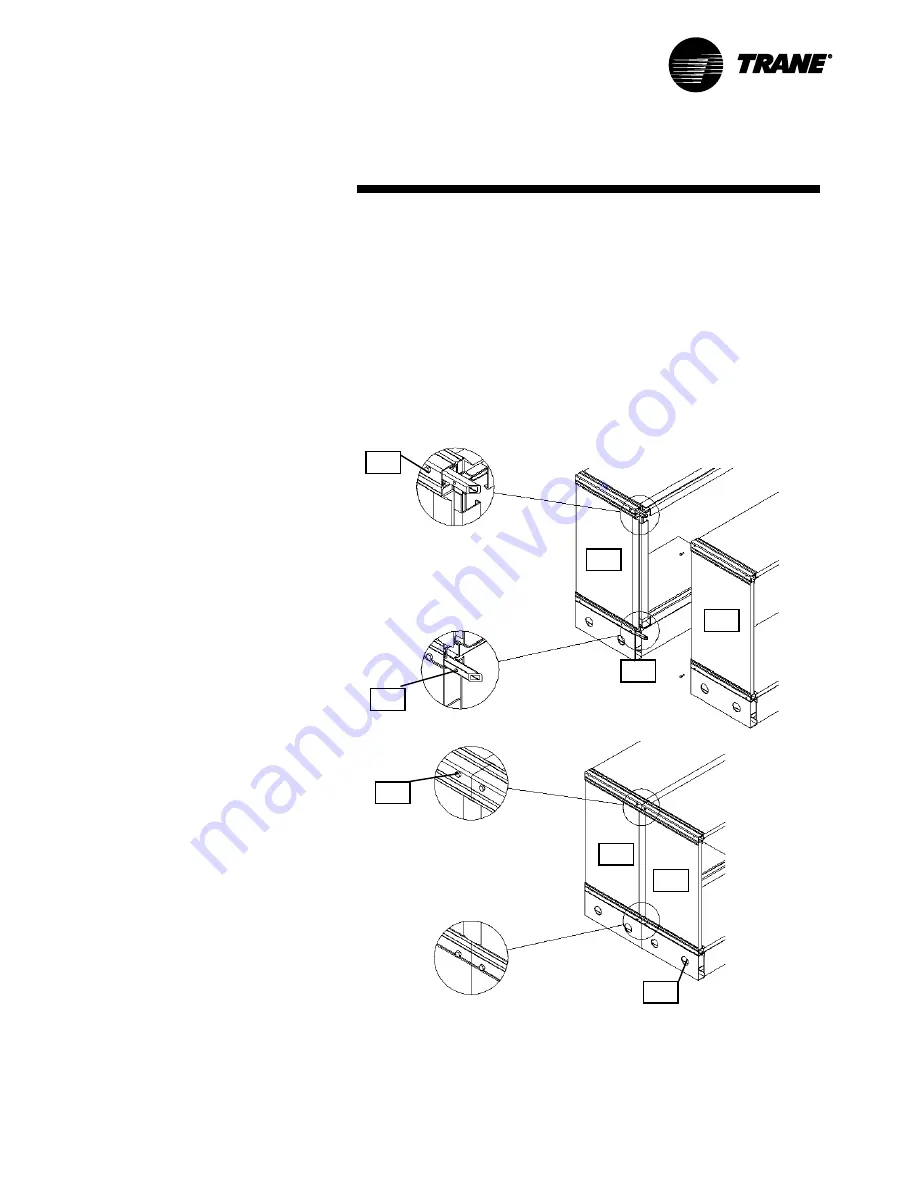

3.Remove 4 M6 fixing

bolts (A)

from the

protruding portion of the 4 framework

joining bars (see Figure 9), then loosen

the remaining 4 bolts that are located

on the fixed side of the break point

joining bars.

Pull together the sections of the unit,

ensuring that the joiner bar in each of

the 4 corners is fitted into its adjoining

section and the plastic “T” section

sealing strip locates over the adjoining

panel.

The 52-mm diameter holes provided in

the unit base frame should be used to

manoeuvre the sections together.

Greased skid plates will greatly assist

the whole assembly operation.

4. Secure the break point joint externally

by replacing the 4 M6 bolts and

washers, which were previously

removed in step (3). Retighten the 8

bolts located on both sides of the break

point joint.

Where applicable, complete the

assembly of the unit as follows:

4.1.3. Fan sections

Bolt the outlet of the fan to the flexible

connection using the M8 bolts provided.

4.1.4. Damper sections

Pop-rivet through the damper spigot and

the adjoining plastic “J” section into the

adjacent fixed panel using 5-mm-

diameter rivets.

4.1.5. Coil sections (with drip pans)

Fix through the top of the drip pan into the

box section using the self-drilling screws,

which are provided. Then seal along all

joints with a waterproof “silicone” based

sealant. We recommend “Siloflex.”

4.1.6. Weatherproof roofs

Slide on the “Doby” cleats, which are

provided, and then fix in position at the

ends with the cleat clips on the roof return

edge using 5mm diameter rivets.

2

1

2

1

CLCH-SVX05A-GB

Figure 9

Figure Notes:

1. Part 1

2.Part 2

3. Break Point

4. Bolts “A”

5. Fixed bolts

6. 52 mm diameter holes

7. 8 x M6 bolts (2 per join)

1

2

5

4

7

6

1

2

3