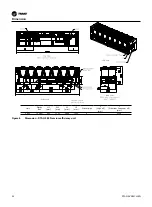

Air vents (to bleed air from system).

Water pressure gauges with shutoff valves.

Vibration eliminators.

Shutoff (isolation) valves. Thermometers (if desired).

Clean-out tees.

Pipe strainer.

Air vents (to bleed air from system).

Water pressure gauges with shutoff valves. Vibration

eliminators.

Shutoff (isolation) valves.

Thermometers.

Clean-out tees.

Balancing valve.

Flow Switch

Water loop systems minimum volume, include chiller,

water piping and indoor unit, all these water

fl

ow should

not less than 9L/kW, in order to keep the unit steady op-

eration and accurate controlled water temperature. If the

volume is lower than this minimum value, should install

a water tank with similar volume, which have build-in

baf

fl

e to get well mixed water.

To protect the unit, water loop must be installed

fl

ow

switch and interlocked with water pump. To interlock the

water pump, please refer to Field Wiring Diagram (line

194 and 346). once the the water

fl

ow of heat exchanger

was below

Table 1

required minimum

fl

ow, water

fl

ow

switch can stop the compressor operation.Water

fl

ow

switch is accessories, its general installation require-

ments outlined below, see

Figure 16

:

Shall be vertically installed in horizontal pipelines or

installed on the vertical tube upward

fl

ow direction.

Please keep away from the elbow, ori

fi

ce or valve ,

before and after the switch keep at least 5 times the

pipe diameter of straight pipe.

Flow switch target slice should be selected and cut

according

Table 10

. Target slice length before usage.

Water bypass cannot be installed between water

fl

ow switch and evaporator, Otherwise, switch can’t

protect evaporator and evaporator may be freeze if

the evaporator inlet water

fl

ow is too small.

Control the screw-in depth of the water

fl

ow switch,

make sure the arrow on the switch is consistent with

the direction of

fl

ow.

To prevent switch vibrate, no air in water loop.

To make sure the

fl

ow switch could cutoff at

fl

ow

smaller than minimum water

fl

ow, according

Figure

17

.

Water

fl

ow switch should be interlocked with water

pump control.

For the other type

fl

ow switch, the speci

fi

c installation

and maintenance requirements can be found in the

fl

ow

switch instructions, which is attached with the unit.

Flow direction

D = Pipe diameter

Figure 16. Water flow switch installation schematic

34

RTAG-SVX001H-EN

Installation - Mechanical