3.ADJUSTMETN

3-9. Tension of deceleration belts

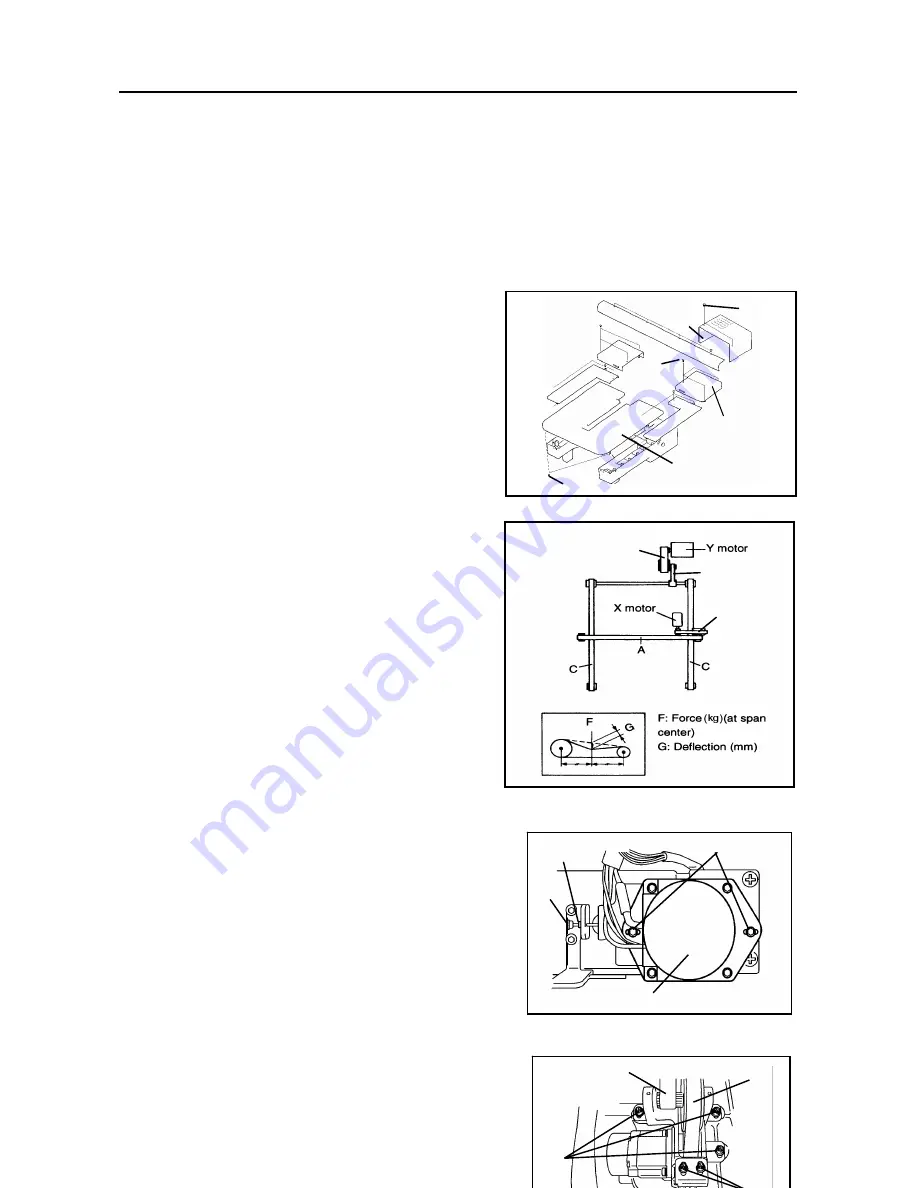

B, D, & E

[Inspection]

(1) Loosen two set screws (a) and

remove the table set. (Fig.1)

(2) Loosen two setting screws (b) and

remove the motor cover. (Fig.1)

(3) Loosen four set screws (c) and

remove the base cover rear R. (Fig.1)

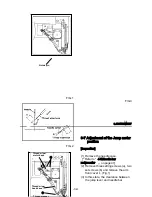

(4) When applying a force of 0.46 ㎏ to

the center of deceleration belt B,

amount of deflection G must be 0.9 ±

0.18mm. (Fig.2)

(5) When applying a force of 0.64 ㎏ to

the center of deceleration belt D,

amount of deflection G must be 1.1±

0.22mm. (Fig.2)

(6) When applying a force of 0.51 ㎏ to

the center of deceleration belt E,

amount of

deflection G must be 1.2 ± 0.24mm.

(Fig.2)

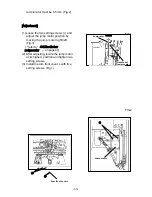

[Adjustment]

(1) If the amount of deflection of

deceleration belt B differs from that

specified, loosen the nut and two set

screws (d), and turn setting screw (e) in

the direction of the arrow. After

adjustment, tighten two set screws (d)

and the nut.. (Fig.3)

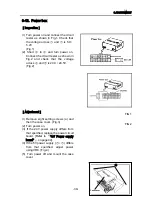

(2) If the amount of deflection of

deceleration belt D differs from that

specified, loosen three set screws (f)

and nut A, then turn setting screw (g)

in the direction of the arrow. After

adjustment, tighten three setting

screws (f) and nut A. (Fig.4)

(3) If the amount of deflection of

deceleration belt E differs from that

specified, loosen two set screws (h)

and nut B, then turn set screw (i) in

the direction of the arrow. After

adjustment, tighten two setting

screws (h) and nut B. (Fig.4)

Note: Check the tension, after tighting

screws (d),(f) and (h).

FIG.1

Motor

cover

(b)

(c)

Base cover

rear R

Table set

(a)

FIG.2

FIG.3

E

D

B

(d)

Nut

(e)

X motor

Belt D

Belt E

-32-

(f)

Содержание ESP9000

Страница 1: ...SERVICE MANUAL Embroidery Machine ESP9000 15 needles...

Страница 2: ......

Страница 13: ...FIG 3 48...

Страница 24: ...FIG 4 59...

Страница 26: ...22 Power supply and consumption 100 120 200 240VAC 50 60Hz 220W 23 Dimensions 835 H x 745 W x 740 D 2...

Страница 36: ...Connection of connector CN 10 Must be connected correctly Replace See P 47 CN10 11...

Страница 40: ...Picker height C 7 9 mm when piker solenoid is ON Adjust See P 27 15...

Страница 54: ...Connection of connector CN 7 Check the connector visually Must be connecte d correctly Replace See P 45 CN7 22...

Страница 58: ...FIG 2 FIG 3 201 3 0 1 0 3 mm 22...

Страница 63: ...FIG 4 e Drive arm FIG 5 27...

Страница 70: ...FIG 3 34...

Страница 72: ...FIG 2 FIG 3 201 3 0 1 0 3 mm 22...

Страница 74: ...FIG 2 FIG 3 Needle bar Stopper Needle bar Connecting stud 24...

Страница 77: ...FIG 4 e Drive arm FIG 5 27...

Страница 84: ...FIG 3 34...

Страница 86: ...FIG 4 31...

Страница 88: ...FIG 4 33...

Страница 90: ...FIG 2 35...

Страница 93: ...2 a Sensor arm 3 38...

Страница 95: ...FIG 3 FIG 4 VR6 Power supply board 40...

Страница 97: ...FIG 3 FIG 4 0 5 to 0 8mm 0 2mm or less Hook support hook support 37...

Страница 100: ...FIG 4 40...

Страница 103: ...FIG 2 Needle bar c Top dead center stopper needle bar connecting stud FIG 3 43...

Страница 105: ...FIG 5 45...

Страница 110: ...FIG 1 FIG 2 FIG 3 c Base cover rear R Table set a FIG 4 Rear cover b b e d Case cover upper Power circuit board f 50...

Страница 111: ...Printed in Japan 2002 8...