Air to Air Heat Exchanger with DX Coil Unit

Installation Manual

Air to Air Heat Exchanger with DX Coil Unit

Installation Manual

– 5 –

3

Restrictions on system construction

System combinations available

The Air to Air Heat Exchanger with DX Coil Unit can be connected to a Super Module Multi system -i.

Range of combination

1. The Air to Air Heat Exchanger with DX Coil Unit can be connected with either one of the following multi systems:

• System with Air to Air Heat Exchanger with DX Coil Unit and air conditioner indoor units

• Air to Air Heat Exchanger with DX Coil Unit system

2. The overall capacity (HP) of air conditioner indoor units and Air to Air Heat Exchanger with DX Coil Unit should

be 80 to 135 % of that of outdoor units.

3. When calculating the connection capacity of the indoor unit, use the following horse power:

System with Air to Air Heat Exchanger with DX Coil Unit and air conditioner indoor units

Air to Air Heat Exchanger with DX Coil Unit system

The Air to Air Heat Exchanger with DX Coil Unit and the concealed duct type fresh air intake unit cannot be used

together in the same system.

Model name

MMD-

VNK502HEXE-TR

VN502HEXE-TR

VNK802HEXE-TR

VN802HEXE-TR

VNK1002HEXE-TR

VN1002HEXE-TR

HP

1.0

1.7

2.0

Air conditioner indoor units

Air to Air Heat Exchanger

with DX Coil Unit

Air to Air Heat Exchanger with DX Coil Unit

4

Selection of installation place

CAUTION

•

Do not install the Air to Air Heat Exchanger with

DX Coil Unit in a location subject to a risk of

exposure to a combustible gas.

If a combustible gas leaks and stays around the unit,

a fire may occur.

•

Install the unit so that the air discharge is located

at least 1.5 m from the nearest fire alarm.

Otherwise, when a fire occurs, the fire alarm may be

late to detect it, or may not detect it at all.

Install the indoor unit in a place where cool / warm

air circulates evenly.

Avoid installing in the following places.

• Places where the outside temperature falls below

5 °C. (If the temperature around the unit falls below

5 °C, water in humidifier freezes and the water will

leak.) (VNK type only)

• Places where air pipes are installed in the ceiling

cavity.

• Place exposed to air with high salt content (seaside

area)

• Place exposed to large quantities of sulfide gas (hot

spring).

(Should the unit be used in these places, special

protective measures are needed.)

• A restaurant kitchen where a lot of oil is used or place

near machines in a factory (Oil adhering to the heat

exchanger and resin part (turbo fan) in the indoor

unit may reduce the performance, generate mist or

dew drop, or deform or damage resin parts.)

• Places where obstacles disturbing the air current

such as a ventilation hole or lighting apparatus are

near the unit. (The performance of the unit may be

deteriorated or the unit may not work due to

disturbance of the air current.)

• Do not use the air conditioner for special purposes

such as preserving food, precision instruments, or

art objects, or where breeding animals or growing

plants are kept. (This may degrade the quality of

preserved materials.)

• Place where any of high-frequency appliances

(including inverter devices, private power

generators, medical equipment, and communication

equipment) and inverter-type fluorescent light is

installed.

(A malfunction of the air conditioner, abnormal

control, or problems due to noise to such appliances

/ equipment may occur.)

• Places where there is something that must not

become wet. When the humidity reaches 80 % or

more, or when the draining pipe is clogged, water

droplets may fall from the unit.

• Place near a door or window exposed to humid

outside air (Dew dropping may form.).

• Place where special spray is used frequently.

• Places such as outdoors or under the eaves (where

rain may fall directly on the unit).

• Do not use the unit in chemical plants with a cooling

system which uses liquid carbon dioxide, etc.

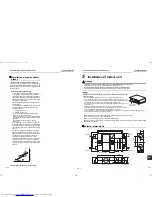

Installation space

Leave ample space for installation or servicing.

REQUIREMENT

• Before installing indoor units, attach any accessories

(drain-up kit, etc.: separately purchased) to them. In

addition, make inspection opening on both sides of

each unit.

• The size of inspection opening should be 600 mm ×

600 mm.

200 mm or

more

1000 mm or

more

200 mm

600 mm

Inspection opening

600 mm

¯

600 mm

9-EN

10-EN

+00ET99805001-2.book Page 5 Tuesday, July 26, 2011 1:39 PM