Installation Manual

– 8 –

EN

Refrigerant piping connection

CAUTION

TAKE NOTE OF THESE 4 IMPORTANT POINTS BELOW FOR PIPING WORK

1. Keep dust and moisture away from inside the connecting pipes.

2. Tightly connect the connection between pipes and the unit.

3. Evacuate the air in the connecting pipes using a VACUUM PUMP.

4. Check for gas leaks at connection points.

Pipe connection method

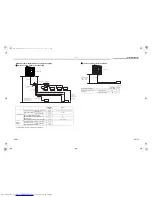

Flaring

1. Cut the pipe with a pipe cutter.

2. Remove the burr inside of the pipe.

When removing the burr, be careful so that chips do not fall into the pipe.

3. Remove the flare nuts attached to the outdoor / indoor unit, then insert them into each of the pipes.

4. Flare the pipes.

See the following table for the projection margin (A) and flaring size (B).

* In case of flaring for R410A with the conventional flare tool, pull the tool out approx. 0.5 mm more than that for R22

to adjust it to the specified flare size.

The copper pipe gauge is useful for adjusting the projection margin size.

Pipe

A

B

Flare Nut

Outside

diameter

Thickness

Rigid

(clutch type)

R410A tool

Imperial

(wing nut type)

R410A tool

Width across

flat

Tighten torque

mm

mm

mm

mm

mm

mm

N•m

kgf•m

6.35

0.8

0 to 0.5

1.0 to 1.5

9.9

17

14 to 18

1.4 to 1.8

9.52

0.8

0 to 0.5

1.0 to 1.5

13.2

22

33 to 42

3.3 to 4.2

12.70

0.8

0 to 0.5

1.0 to 1.5

16.6

26

49 to 61

4.9 to 6.1

15.88

1.0

0 to 0.5

1.0 to 1.5

19.7

29

63 to 77

6.6 to 7.7

90°

Obliquity

Roughness

Warp

A

B

REQUIREMENT

• For a brazing work of the refrigerant pipes, be sure to use nitrogen gas in order to prevent oxidation of the inside of

the pipes; otherwise clogging of the refrigerating cycle due to oxidized scale may occur.

• Use clean and new pipes for the refrigerant pipes and perform piping work so that water or dust does not

contaminate the refrigerant.

* Remove all flux after brazing.

• Be sure to use two spanners to loosen or tighten the flare nut. If one spanner is used, the required level of

tightening cannot be obtained. Tighten the flare nut with the specified torque.

• Do not apply refrigerant oil to the surface of the flare.

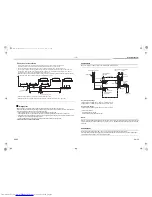

Coupling size of brazed pipe

(Unit: mm)

Connected section

External size

Internal size

Standard outer dia. of

connected copper

pipe

Connected section

Min. thickness of

coupling

External size

Internal size

Min. depth of

insertion

Oval value

Standard outer dia.

(Allowable difference)

C

F

K

G

6.35

6.35 (±0.03)

6.45 (

)

7

6

0.06 or less

0.50

9.52

9.52 (±0.03)

9.62 (

)

8

7

0.08 or less

0.60

12.70

12.70 (±0.03)

12.81 (

)

9

8

0.10 or less

0.70

15.88

15.88 (±0.03)

16.00 (

)

9

8

0.13 or less

0.80

K

ØC

G

ØF

+0.04

-0.02

+0.04

-0.02

+0.04

-0.02

+0.04

-0.02

EN-15

EN-16

2FAN_IM_DB04905901-00.book Page 8 Friday, October 24, 2014 3:19 PM

1

9

.

05

1.0

0 to 0.5

1.0 to 1.5

24

.

0

36

100

to

120

10

to

12

1

9

.

05

1

9

.

05

(±0.03)

11

10

0.1

5

or less

0

.

8

0

1

9

.

19

(

+0

-0.

.

0

0

3

3

)

Содержание MCY-MAP0401TP Series

Страница 32: ......