Reelmaster 5500-D

Hydraulic System (Rev. C)

Page 4 - 36

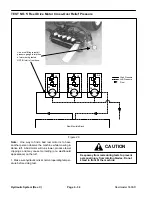

TEST NO. 7: Gear Pump Section (P3) Flow and Relief Valve Pressure

(Using Tester with Pressure Gauges and Flow Meter)

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes.

2. Make sure machine is parked on a level surface with

the cutting units lowered and off. Make sure engine is

off.

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS, and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

3. With the engine off and cutting units lowered, install

tester in series between pressure hose and the gear

pump section P3 (Fig. 22). Make sure the tester flow

control valve is OPEN.

IMPORTANT: Make sure that the oil flow indicator

arrow on the flow gauge is showing that the oil will

flow from the pump, through the tester and into the

valve block.

IMPORTANT: The pump is a positive displacement

type. If pump flow is completely restricted or

stopped, damage to the pump, tester or other com-

ponents could occur.

4. Make sure the parking brake is engaged. Start the

engine and move throttle to full speed (3000 RPM). DO

NOT engage the cutting units.

5. While watching pressure gauges, slowly close flow

control valve until 1000 PSI (69 bar) is obtained on

gauge. Verify pump speed at 3000 RPM at the transmis-

sion input shaft from the engine.

TESTER READING: Flow not less than 4 GPM at 1000

PSI (69 bar).

6. If flow was lower than 4 GPM or a pressure of 1000

PSI (69 bar) cannot be obtained, check for restriction in

pump intake line. If not restricted, verify relief setting

first, then remove pump and repair or replace as neces-

sary.

7. While watching pressure gauges, slowly close flow

control valve further until 1450 PSI (100 bar) is main-

tained as the relief valve lifts.

TESTER READING: Relief valve setting of 1450 PSI

(100 bar).

1. Outlet to steering

2. Gear pump

Figure 22

1

2

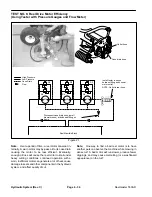

1. Gear

pump

2. Relief

valve

Figure 23

1

2

8. If pressure is maintained below 1450 PSI (100 bar)

or pressure goes beyond 1450 PSI (100 bar), replace

the relief valve (Fig. 23).

9. Stop engine. Remove tester and reinstall hoses.

Содержание 00075SL

Страница 2: ...Reelmaster 5500 D ...

Страница 4: ...Reelmaster 5500 D ...

Страница 6: ...Reelmaster 5500 D ...

Страница 12: ...0 09375 Rev D Reelmaster 5500 D Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Страница 49: ...Hydraulic System Reelmaster 5500 D Hydraulic System Rev C Page 4 11 This page is intentionally blank ...

Страница 64: ...Reelmaster 5500 D Hydraulic System Rev C Page 4 26 This page is intentionally blank ...

Страница 89: ...Hydraulic System Reelmaster 5500 D Hydraulic System Rev C Page 4 51 This page is intentionally blank ...

Страница 109: ...Hydraulic System Reelmaster 5500 D Hydraulic System Rev C Page 4 71 This page is intentionally blank ...

Страница 115: ...Hydraulic System Reelmaster 5500 D Hydraulic System Rev C Page 4 77 This page is intentionally blank ...

Страница 170: ...Reelmaster 5500 D Page 5 40 Electrical System Rev C ...

Страница 192: ...Reelmaster 5500 D Differential Axle Page 6 22 ...

Страница 254: ...Reelmaster 5500 D Groomer Rev C Page 8 1 14 ...

Страница 278: ...Reelmaster 5500 D Page 10 2 Electrical Diagrams Rev C ...

Страница 284: ...Rev C Page 10 8 Harness Drawing Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Страница 285: ...Rev C Page 10 9 Harness Diagram Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Страница 286: ...Rev C Page 10 10 Harness Drawing Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Страница 287: ...Rev C Page 10 11 Harness Diagram Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Страница 288: ...Rev C Page 10 12 Harness Drawing Reelmaster 5500 D Serial Number Above 230000000 ...

Страница 289: ...Rev C Page 10 13 Harness Diagram Reelmaster 5500 D Serial Number Above 230000000 ...

Страница 290: ...Reelmaster 5500 D ...