4WD Rear

Axle

Reelmaster 5500-D

4WD Rear Axle (Rev. C)

Page 9 - 13

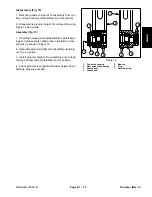

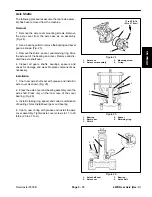

5. Determine necessary quantity of support shims.

A. Lubricate the axle case support bushing with a

thin coat of grease and slide axle case support onto

knuckle pin.

B. Position support shims that were removed during

disassembly between axle case support and axle

case. Install mounting screws into axle case. Slowly

tighten screws while frequently checking for clear-

ance (vertical endplay) between axle case support

and knuckle pin. If binding of components is noted

before screws are fully tightened, add additional sup-

port shims. Torque screws from 57 to 67 ft−lb (77 to

91 N−m).

C. Use dial indicator to measure vertical endplay of

axle case (Fig. 19).

AXLE CASE ASSEMBLY ENDPLAY:

0.001 to 0.008 in. (0.02 to 0.20 mm)

D. Adjust endplay by increasing or reducing number

of axle case support shims.

NOTE: Axle case support shims are available in

0.004 in. (0.1 mm), 0.008 in. (0.2 mm), and 0.016 in.

(0.4 mm) thickness.

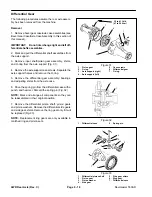

6. After correct support shims have been determined,

remove mounting screws, apply heavy strength thread−

locking compound to screw threads, reinstall screws,

and torque from 57 to 67 ft−lb (77 to 91 N−m).

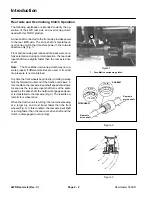

IMPORTANT: Correct engagement between bevel

gears is critical to axle performance and durability.

7. Temporarily install the bevel gear case/axle case as-

sembly on the axle support. Position a dial indicator at

the tooths center. Prevent the axle from turning and

measure the upper bevel gear to differential shaft gear

backlash (Fig. 20).

UPPER BEVEL GEAR BACKLASH:

0.004 to 0.016 in. (0.10 to 0.40 mm)

8. Adjust backlash by increasing or reducing axle bear-

ing shim thickness (see Differential Shafts in this section

of this manual).

NOTE: Axle bearing shims are available in 0.004 in.

(0.1 mm), 0.008 in. (0.2 mm), and 0.020 in. (0.5 mm)

thickness.

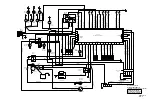

1. Axle case support

2. Axle

case

3. Bevel

gearcase

4. Dial

indicator

5. Knuckle

pin

6. Support shim location

Figure 19

1

2

4

5

3

6

VERTICAL

ENDPLAY

57 to 67 ft−lb

(77 to 91 N−m)

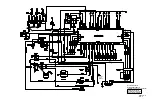

1. Axle

support

2. Upper bevel gear

3. Differential shaft gear

4. Dial

indicator

5. Axle bearing shims

Figure 20

1

2

3

4

5

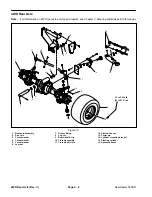

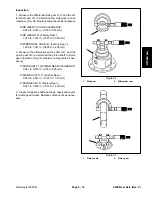

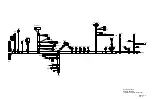

1. Axle cover assembly

2. Lower bevel gear

3. Axle

gear

4. Dial

indicator

5. Axle bearing shims

Figure 21

1

2

3

4

5

Содержание 00075SL

Страница 2: ...Reelmaster 5500 D ...

Страница 4: ...Reelmaster 5500 D ...

Страница 6: ...Reelmaster 5500 D ...

Страница 12: ...0 09375 Rev D Reelmaster 5500 D Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Страница 49: ...Hydraulic System Reelmaster 5500 D Hydraulic System Rev C Page 4 11 This page is intentionally blank ...

Страница 64: ...Reelmaster 5500 D Hydraulic System Rev C Page 4 26 This page is intentionally blank ...

Страница 89: ...Hydraulic System Reelmaster 5500 D Hydraulic System Rev C Page 4 51 This page is intentionally blank ...

Страница 109: ...Hydraulic System Reelmaster 5500 D Hydraulic System Rev C Page 4 71 This page is intentionally blank ...

Страница 115: ...Hydraulic System Reelmaster 5500 D Hydraulic System Rev C Page 4 77 This page is intentionally blank ...

Страница 170: ...Reelmaster 5500 D Page 5 40 Electrical System Rev C ...

Страница 192: ...Reelmaster 5500 D Differential Axle Page 6 22 ...

Страница 254: ...Reelmaster 5500 D Groomer Rev C Page 8 1 14 ...

Страница 278: ...Reelmaster 5500 D Page 10 2 Electrical Diagrams Rev C ...

Страница 284: ...Rev C Page 10 8 Harness Drawing Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Страница 285: ...Rev C Page 10 9 Harness Diagram Reelmaster 5500 D Serial Number 210000401 to 210999999 ...

Страница 286: ...Rev C Page 10 10 Harness Drawing Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Страница 287: ...Rev C Page 10 11 Harness Diagram Reelmaster 5500 D Serial Number 220000001 to 220999999 ...

Страница 288: ...Rev C Page 10 12 Harness Drawing Reelmaster 5500 D Serial Number Above 230000000 ...

Страница 289: ...Rev C Page 10 13 Harness Diagram Reelmaster 5500 D Serial Number Above 230000000 ...

Страница 290: ...Reelmaster 5500 D ...