GIRE-097-2-2

47

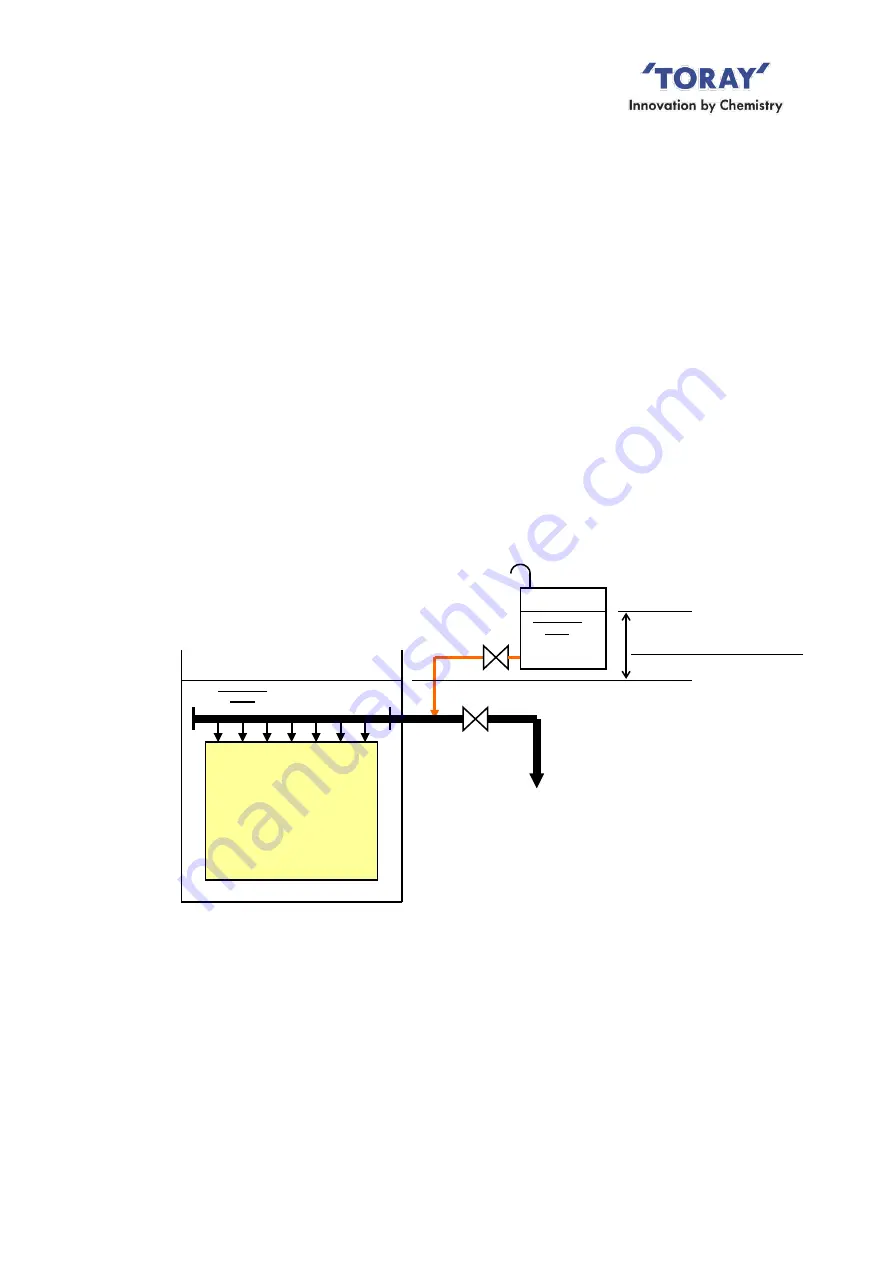

b. Chemical cleaning with the chemical tank located above the membrane submerged

tank (Fig.VIII-2)

(i)

Confirm that the chemical injection valve is closed.

(ii)

Provide the chemical tank with specified amounts of the chemical.

(iii) Stop filtration, stop aeration, and close the filtrate valve.

(iv) Slowly open the chemical injection valve to inject chemicals.

(v)

After injecting the chemical, hold the equipment for 1 to 3 hours.

(vi)

Close the chemical valve, open the filtrate valve, and start aeration. Then,

restart filtration operation.

* The chemical may remain in the permeated water in an early stage of

filtration (for a period of 2 or more intermittent cycles). Send back the

permeated water to the raw water tank, or dispose of it in accordance with

applicable legal standards for waste disposal. Before restarting the normal

operation, check the pH and/or Cl concentration of the permeated water.

Fig.VIII-2 Chemical Cleaning with Chemical Tank Located

above Membrane Submerged Tank

c. Chemical cleaning with the chemical feed pump and relief valve (Fig.VIII-3)

(i)

Confirm that the chemical feed pump is stopped and the top of relief piping is

located at 1 m or lower height from membrane submerged tank water level.

(ii)

Provide the chemical tank with specified amounts of chemical.

Module

Manifold

Permeated

water valve

Chemical tank

1,000 mm (=10 kPa) or less

Low water level of

Membrane

Submerged Tank

Chemical

injection valve