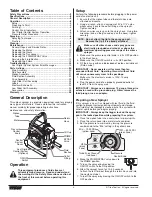

Servicing the Fluid Section

Use the following procedures to service the valves and repack

the fluid section. Perform the following steps before

performing any maintenance on the fluid section.

1. Loosen and remove the four front cover screws. Remove

the front cover.

2. Stop the sprayer at the bottom of its stroke so that the

piston is in its lowest position.

3. Perform the Pressure Relief Procedure and unplug the

sprayer.

Before proceeding, follow the Pressure Relief

Procedure outlined previously in this manual.

Additionally, follow all other warnings to reduce

the risk of an injection injury, injury from moving

parts or electric shock. Always unplug the

sprayer before servicing!

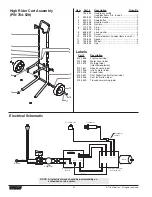

4. For High Rider cart units, remove the return hose from the

hose clip on the siphon tube. Unscrew the siphon tube

from the foot valve housing.

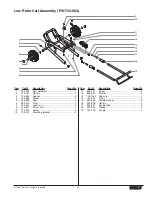

5. For Skid and Low Rider units, unscrew the return hose

assembly from the pump block. Remove the retaining clip

from the bottom of the foot valve housing. Remove the

siphon assembly.

6. Tilt the sprayer back for easy access to the fluid section.

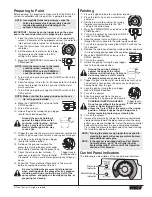

Servicing the Valves

The design of the fluid section

allows access to the foot valve and

seat as well as the outlet valve and

seat without completely

disassembling the fluid section. It

is possible that the valves may not

seat properly because of debris

stuck in the foot valve seat or outlet

valve seat. Use the following

instructions to clean the valves and

reverse or replace the seats.

1. Using a wrench, loosen and

remove the foot valve housing

from the pump block.

2. Clean out any debris in the

foot valve housing and

examine the valve housing and

seat. If the seat is damaged, reverse or replace the seat.

3. Using a 5/16” hex wrench, loosen and remove the outlet

valve retainer from the piston rod.

4. Clean out any debris and

examine the outlet valve housing

and seat. If the seat is damaged,

reverse or replace the seat.

5. Remove, clean, and inspect the outlet cage, crush

washer, and outlet valve ball. Replace if they are worn or

damaged.

6. Reassemble the valves by reversing the steps above.

NOTE: During reassembly of the outlet valve, apply

one drop of Loctite (included in the repacking

kit) to the threads of the outlet valve retainer

before threading it into the piston rod. Then,

torque the retainer to 144 in./lbs. (12 ft./lbs.).

NOTE: The outlet cage always must be used with the

crush washer. They are included together in

the repacking kit as assembly P/N 704-642.

NOTE: Always service the

outlet valve with the

piston rod attached to

the pump. This will

prevent the piston rod

from rotating during

disassembly of the

outlet valve.

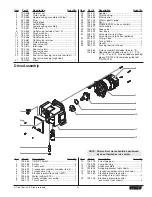

Outlet Valve

Retainer

Outlet Valve

Seat

Outlet Valve

Ball

Outlet Cage

Crush

Washer

Piston Rod

Foot Valve

Housing

Foot Valve

Seat

Foot Valve

Ball

Bushing

Teflon

O-Ring

Inlet Cage

Foot Valve

Seal

Pump Block

12

© Titan Tool Inc. All rights reserved.

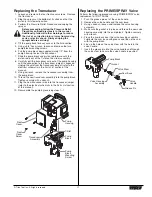

Repacking the Fluid Section

1. Remove the foot valve assembly using the steps in the

“Servicing the Valves” procedure above.

2. Using 3/8” a hex

wrench, loosen and

remove the two pump

block mounting

screws.

3. Pull the pump block

down approximately

1/2” from the pump

housing.

4. Slide the pump block

and piston rod

forward until the

piston rod is out of

the T-slot on the

slider assembly.

5. Slide the piston rod

out through the

bottom of the pump

block

6. Loosen and remove

the retainer nut and

piston guide from the

pump block.

7. Remove the upper

and lower packings

from the pump block.

8. Clean the pump block

and install the new upper and lower packings. Refer to

the illustration below for proper packing orientation.

9. Inspect the piston rod for wear and replace if necessary.

10. Reassemble the outlet valve assembly into the piston rod.

Tighten the outlet valve retainer with a wrench until secure.

IMPORTANT: Never use a wrench on the piston itself.

This could cause damage to the piston and cause leakage.

11. Insert the piston guide into the retainer nut. Thread the

retainer nut into the pump block until it is hand tight.

12. Slide the piston guide tool (included in the repacking kit)

over the top of the piston rod and insert the piston rod

through the bottom of the pump block. Using a rubber

mallet, tap the bottom of the piston rod lightly until the

piston rod is in position in the pump block.

13. Using a wrench, tighten the retainer nut securely.

14. Slide the top of the piston rod into the T-slot on the slider

assembly.

15. Position the pump block underneath the pump housing

and push up until it rests against the pump housing.

16. Thread the pump block mounting screws through the

pump block and into the pump housing. Tighten securely.

NOTE: Coat the piston guide tool and the piston rod

with grease before inserting them into the

pump block.

NOTE: Use the T-slot on the slider assembly to hold

the piston rod in position while securing the

outlet valve retainer.

Install upper packing

with raised lip and O-ring

facing down.

O-Ring

Raised Lip

Beveled Edge

Install lower packing

with the beveled

edge facing up.

Slider

Assembly

Retainer

Nut

Piston

Guide

Upper

Packing

Pump

Block

Lower

Packing

Pump Block

Mounting

Screw

Piston Rod

T-Slot

NOTE: The outlet valve does not need to be

disassembled from the piston rod for this

procedure.

Содержание High Rider Basic

Страница 27: ... Titan Tool Inc All rights reserved 27 Notes ...