GPX4000LZ Glass Processor

Chapter 8: Specifications

Rev I, September 15, 2021

Page 65

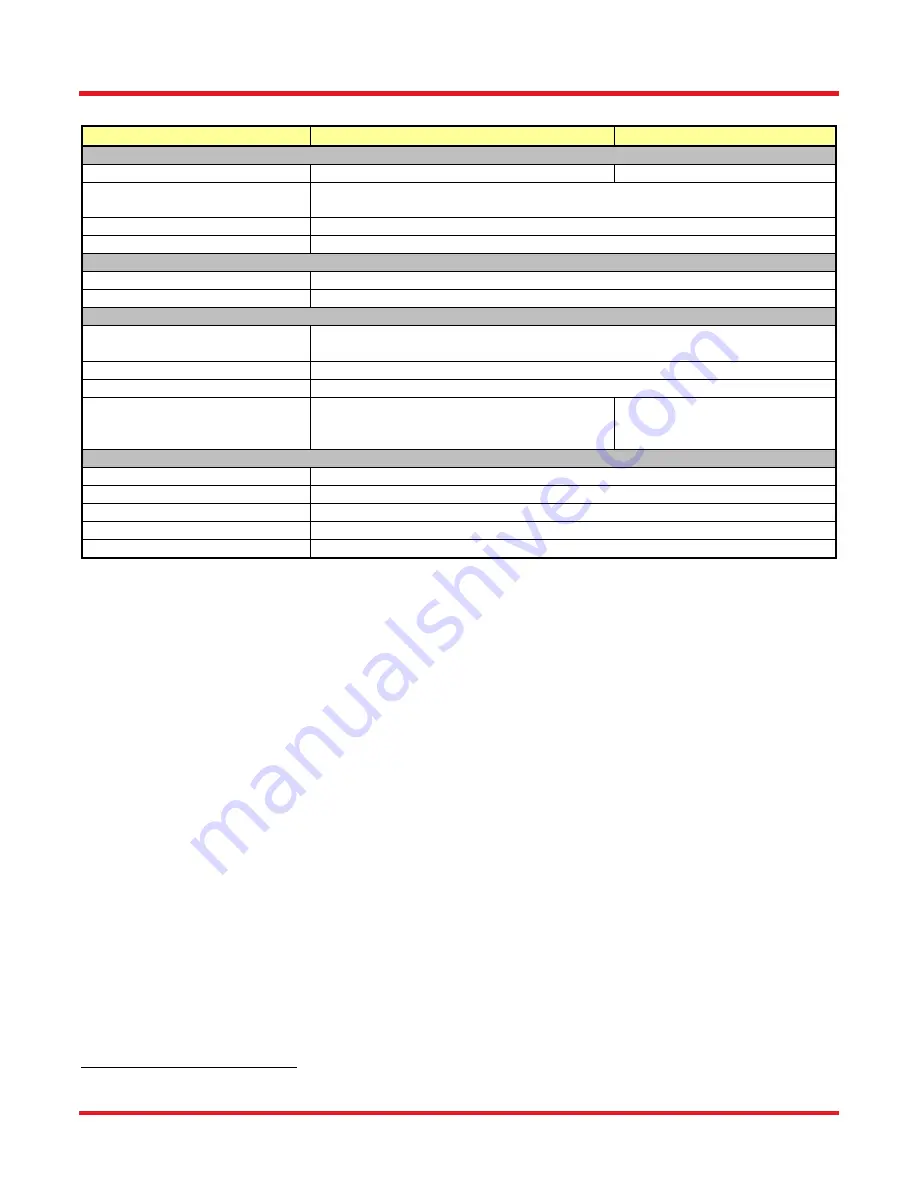

Operating Mode

Laser Mode

Filament Mode

Tapering

Tapering Length

Up to 140 mm (Max)

h

Up to 150 mm (Max)

h

Tapering Ratio (Max)

Adiabatic Tapers up to 1:10

(Ratios Up to 1:150 Possible)

Tapering Speed

1 mm/s (Typical)

i

Adiabatic Tapering Loss

<0.2 dB (Typical)

Computer and Software

PC Computer

Included

Splice Files

Built-In Library for Common Fibers and Processes

Physical

Size (L x W x H)

36.4" x 31.3" x 44.2"

(925 mm x 795 mm x 1123 mm)

Weight

300 lbs (136 kg)

Power Input

100 - 240 VAC, 47 - 63 Hz, 14.7 A

Gas Supply

N/A

Argon, >99.999%

Purity at 12 psig (Not

Included)

Environmental

Operating Temperature

15 to 40 °C

Altitude Range

0 to 2000 m Above Sea Level

Operating Humidity

0% to 75% Relative Humidity (Non-Condensing)

Storage Temperature

-20 to 60 °C

Storage Humidity

0% to 90% Relative Humidity (Non-Condensing)

h

Dependent on Taper Geometry

i

Tapering speed depends highly on the type of process used. 1 mm/s is a typical speed for a standard tapering process.

Содержание Vytran GPX4000LZ

Страница 1: ...GPX4000LZ Glass Processor User Guide ...

Страница 2: ......

Страница 73: ...www thorlabs com ...