IOM CRUZcontrol®

P/N: 90480009

Revision Date: 03/18/2019

Page

52

of

58

2. The release of product from the accumulation conveyor could be logically controlled so as to

limit the release rate. If the NBA®23 running at 180 feet per minute were to be given a

CRUZcontrol Singulation Release signal for 3.3 seconds, and then kept off for 2.7 seconds, with

that sequence repeating, the theoretical release rate should be close to 100 product-feet per

minute (180 fpm x 3.3 sec. / (3.3 sec. + 2.7 sec.)). The actual release rate could be more, with

product coast and shorter than zone length product lengths allowing more product than

expected to progress past the release point. Assuming that the release signal is PLC

controlled, an advantage to this approach is that the release sequence timing could be easily

altered to increase or decrease the release rate.

3. The CRUZcontrol Logic Assembly at the final discharge zone could be Basic Logic, with all

other upstream Logic Assemblies Progressive Logic. This would reduce the NBA

23 release

rate while still retaining the infeed and throughput rate benefits of Progressive Logic. The

release rate would be a function of the speed of the accumulation conveyor, the speed of the

receiving conveyor, and also the size and weight characteristics of the conveyed product. If the

NBA 23 running at 180 feet per minute had a Basic Logic Assembly at only the discharge end,

the release rate would be closer to the 100 product-feet per minute capacity of the downstream

induction belt conveyor.

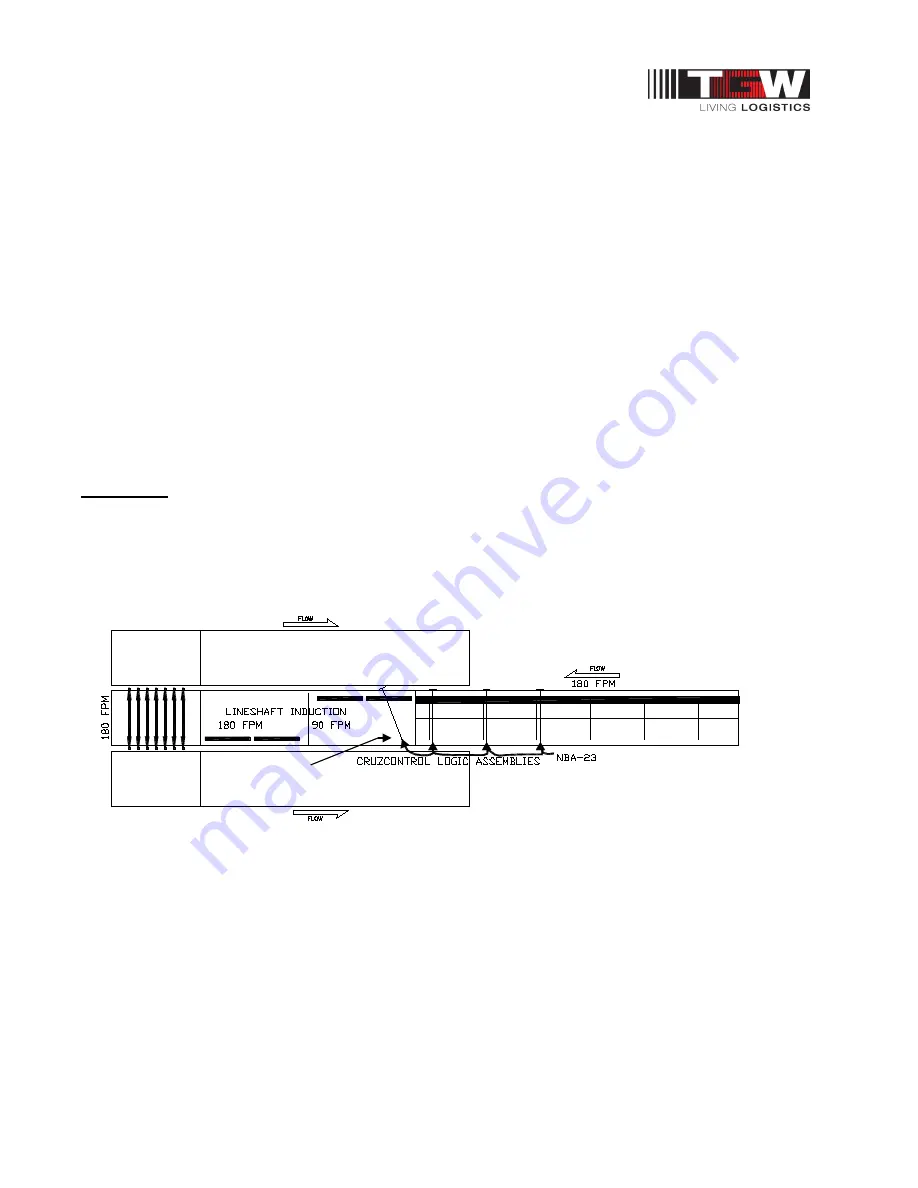

Example 6:

NBA 23 accumulation release to XenoROL®.

NBA 23 conveyor, when accumulating and subsequently releasing accumulated product, will result in

some amount of line pressure at the discharge end of the conveyor. This is caused by the momentum

of moving product coasting to a stop as it accumulates. In applications where the NBA 23 feeds

XenoROL conveyor, controlling the release so as to avoid problems caused by the line pressure is

essential. The following is shown as an example:

The

NBA 23 is running at 180 feet per minute, feeding the lineshaft induction section prior to a pick zone

module diverter. Without proper control of the discharge from the NBA 23, cartons released to the

lineshaft induction could possibly overdrive it and push past the 90 fpm section onto the 180 fpm section,

not permitting product gapping to occur as required for the diverter to function properly. This is a concern

when using Basic accumulation, and even more so when using Progressive accumulation.

Discharge Logic

Assembly