32

ENG

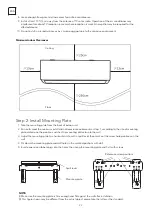

Manifold gauge

Pressure gauge

High pressure valve

Low pressure valve

Charge hose

Vacuum pump

compound gauge

Low pressure valve

Service port

High pressure valve

Valve protective caps

Pressure hose

Inspections Before Test Run

Do the following checks before test run.

TEST OPERATION

Description

Inspection method

Electrical safety

inspection

• Check whether the power supply voltage complies with specification.

• Check whether there is any wrong or missing connection between the power

lines, signal line and earth wires.

• Check whether the earth resistance and insulation resistance comply with

requirements.

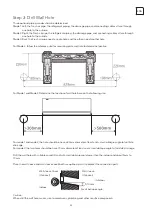

Installation safety

inspection

• Confirm the direction and smoothness of drainage pipe.

• Confirm that the joint of refrigerant pipe is installed completely.

• Confirm the safety of outdoor unit, mounting plate and indoor unit installation.

• Confirm that the valves are fully open.

• Confirm that there are no foreign objects or tools left inside the unit.

• Complete installation of indoor unit air inlet grille and panel.

Refrigerant leakage

detection

• The piping joint, the connector of the two valves of the outdoor unit, the valve

spool, the welding port, etc., where leakage may occur.

• Foam detection method:

Apply soapy water or foam evenly on the parts where leakage may occur, and

observe whether bubbles appear or not, if not, it indicates that the leakage

detection result is safe.

• Leak detector method:

Use a professional leak detector and read the instruction of operation, detect at

the position where leakage may occur.

• The duration of leak detection for each position should last for 3 minutes or

more;

If the test result shows that there is leakage, the nut should be tightened and

tested again until there is no leakage;

After the leak detection is completed, wrap the exposed pip connector of indoor

unit with thermal insulation material and wrap with insulation tape.

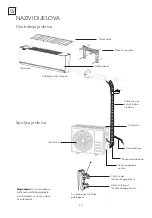

Содержание TT37AF-1232IAW

Страница 353: ......

Страница 354: ...www tesla info ...