409-10100

18 of 59

Rev C

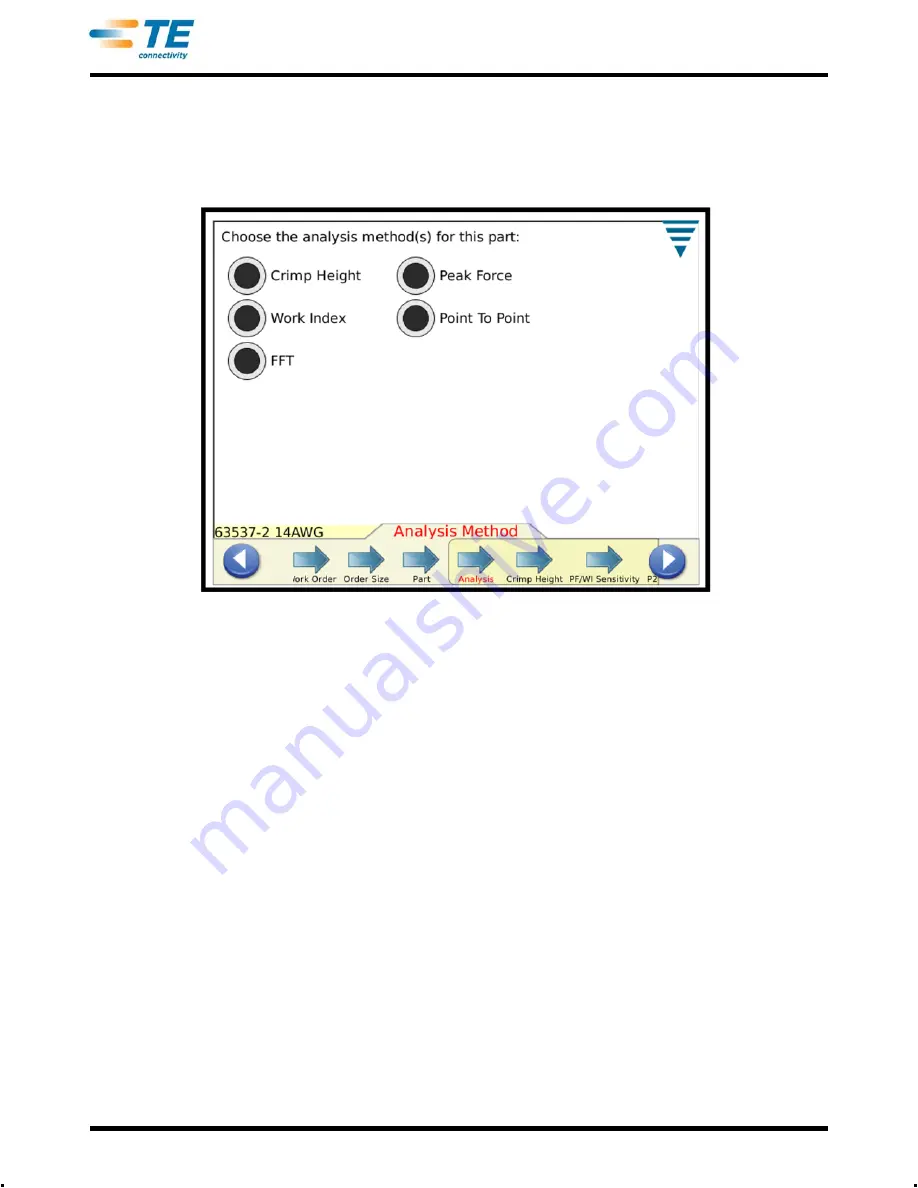

4.5. Analysis Methods

Once you touch the Analysis icon, you will notice that the number of selections in the task bar increase to

provide more choices for editing parameters for the Analysis methods. First, start by choosing the analysis

method(s) for the part. Available analysis methods are: Crimp Height (only on TE terminators), Peak Force,

Work Index, Point to Point, and FFT (systems with just a force sensor can only use the Peak Force and FFT

methods). The Default for a new part is all analysis methods selected.

4.6. Crimp Height

If Crimp Height is selected, touch the Crimp Height arrow or the right arrow icon to move to the next task.

Enter the specific Crimp Height and Tolerance for the part by touching the appropriate box. For the entry of

tolerance, if the tolerance from the manufacturer is +/- 0.002” inches enter 0.002” inches

Select the Update Control Limit radio button to turn on the feature that tells the monitor to automatically

calculate a control limit for the part during production. The Default Control Limit initializes to 0.0015 inches and

will automatically change once 30 production crimps have occurred.

The user can specify their own control limit if they do not want to have one updated for them. The control limit is

also important with the autoadjust feature on some G-terminators. When the average crimp height of three

consecutive PASS crimps is outside the Control Limit the autoadjust motor on the G-terminator will make an

adjustment to bring the crimp height back within the control limit range.

Содержание Crimp Quality Monitor II

Страница 30: ...409 10100 30 of 59 Rev C...

Страница 41: ...409 10100 41 of 59 Rev C...