30

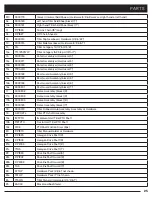

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

POSSIBLE SOLUTION

Cannot attach PTO shaft to the

tractor

PTO shaft is too long, PTO yoke

attachment pin is seized.

Cut PTO shaft per OM

instructions, lubricate

attachment pin.

Tillage depth insufficient

Tractor is holding tiller up,

Tractor has insufficient power,

skid shoes preventing lowering,

tines are worn, ground is too

hard.

Adjust lift arm settings on

tractor, increase tractor PTO

speed, adjust tiller skidshoes,

replace tines, make multiple

passes.

Soil is not tilled fine enough

Ground speed too fast, PTO

speed too slow, tines assembled

incorrectly.

Slow tractor ground speed,

Increase tractor PTO speed,

check tine assembly.

Driveline vibrates

Universal joint is worn, debris

wrapped around tine bar,

driveline is at extreme angle.

Replace universal joint/cross

bearing, remove debris, lower

tiller and adjust tractor lift stop.

Constant abnormal gearbox

noise

Low oil level, worn gears,

gearbox bearings.

Check oil level, replace gears/

gearbox, replace bearings.

Tiller makes intermittent/

abnormal noise

Tines are loose, gearbox has

damaged tooth, debris is

wrapped around tine bar.

Tighten tines, replace damaged

gear, clear debris.

Gearbox is overheating

Oil level is low, gearbox needs

service, ventplug is seized, tiller

load is too great.

Check oil level, replace old oil,

replace ventplug, reduce ground

speed/tilling depth.

Oil Leaking from gearbox

Seals and or gaskets are

damaged, gearbox is overfilled

with oil.

Replace seals or gaskets, drain

oil to correct level.

Rotor will not turn

Tractor PTO is not engaged,

gear drive has damage, friction

clutch not adjusted properly.

Engage tractor PTO, inspect and

repair gears, reduce tiller load or

adjust clutch.

Tiller shaking

Ground is compacted and or dry,

debris entangled in tines

Make multiple passes with

shorter tilling depth, irrigate soil,

clear debris.

Rear tailgate impacts tines

Tailgate adjustment chain in

wrong position.

Adjust tailgate adjustment chain

to hold tailgate higher.