PKIR, PKIS

| PP-28_201612 | 37 / 48

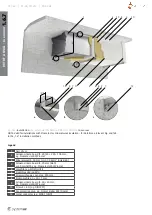

1.1 WET

INSTALLATION EI120S - using plaster mix-

ture, mortar or concrete (Fig. 5, 6)

This installation can be used for fire dampers as per Tab.1 and 2.

1. For installation of a round damper, prepare a round opening of

diameter

DN

+ 80 mm, for a rectangular damper a rectangular

opening with dimensions

W

+ 120 mm and

H

+ 120 mm (as

per Fig. 1 through 4 and Tab. 5 and 7), the opening surfaces

must be even and cleaned off. The flexible wall opening must

be reinforced as per the standards for plasterboard walls.

2. Insert the closed damper into the middle of the opening so

that the damper blade is in the wall. Use the bendable hanger

(1; or hangers, if there are two of them) to secure the dam-

per against the wall using a suitable screw (3; recommended

screw diameter 5,5 - for example DIN7981).

3. Fill in the area between the wall and the damper with plaster

mixture, mortar or concrete (2), while paying attention to

prevent fouling of the damper’s functional parts, which could

limit its correct functionality. The best way is to cover the

functional parts during installation. The seepage of the filling

material can be prevented by using the supplied PRR-PKI /

PRS-PKI coverplates. However, these are not required for wet

installation.

First let the plaster mixture or mortar or concrete harden

and then perform the next steps!

4. If needed, uncover and clean the damper after installation.

5. Check the damper functionality

1.2 DRY

INSTALLATION EI90S - using mineral wool

and coverplates (Fig. 7, 8)

This installation can be used for fire dampers as per Tab.1 and 2.

1. For installation of a round damper, prepare a round opening of

diameter

DN

+ 120 mm, for a rectangular damper a rectangular

opening with dimensions

W

+ 120 mm and

H

+ 120 mm (as

per Fig. 1 through 4 and Tab. 9 and 11), the opening surfaces

must be even and cleaned off. The flexible wall opening must

be reinforced as per the standards for plasterboard walls.

2. (Applies only to PKIS-EI90S)

Insert the closed damper into the middle of the opening so

that the damper blade is in the wall. Use the bendable hanger

(1) to secure the damper against the wall using a suitable

screw (3; recommended screw diameter 5,5 - for example

DIN7981).

3. (Applies only to PKIS-EI90S)

From the hanger (hangers) side close the gap between the

damper and the mounting opening for the round damper

using PRR-PKI or PRS-PKI coverplates (4), for the rectangular

damper with PRS-PKI coverplates using screws (3) through

pre-drilled holes.

4. (Applies only to PKIS3G and PKIR3G)

With these dampers it is necessary to install the bendable

hangers (1) onto the coverplates using suitable screws (3;

recommended screw diameter 5,5 - for example DIN7981).

Therefore it is necessary to begin by installing the two neigh-

boring PRR-PKI or PRS-PKI coverplates (4) from the mecha-

nism side and secure them against the wall in such way that

the damper can be passed through them into the opening

and secure both the coverplates and the damper into the wall

using suitable screws (3; recommended screw diameter 5,5

- for example DIN 7981). Subsequently mount the remaining

coverplates from the mechanism side.

5. Fill in the area between the wall and the damper with mineral

wool (2) with density at least 50 kg/m

3

thoroughly but in

such way that will not deform the damper housing, while

paying attention to prevent fouling of the damper’s functional

parts, which could limit its correct functionality.

6. Close the gap between the damper and the mounting

opening, for a round damper use PRR-PKI coverplates, for a

rectangular damper use PRS-PKI coverplates with screws (5)

through pre-drilled holes.

7. All the gaps between the coverplates, between coverpla-

tes and the wall, between coverplates and the fire damper

need to be filled with fire resistant mastic (e.g. Promaseal-

A/fa. Promat).

8. If needed, clean the damper after installation.

9. Check the damper functionality (see the operation manual).

1.3

INSTALLATION INTO A

SOFT CROSSING

EI90S

(Fig. 9, 10)

This installation can be used for fire dampers as per Tab.1 and 2.

1. For installation of a round damper prepare a round opening of

diameter

DN

+ 120 mm, for a rectangular damper a rectangular

opening with dimensions

W

+ 120 mm and

H

+ 120 mm (as

per Fig. 1 through 4 and Tab. 13 and 15), the opening surfaces

must be even and cleaned off. The flexible wall opening must

be reinforced as per the standards for plasterboard walls.

2. Prepare mineral wool installation segments (2 with cubic

weight 150 kg/m

3

, thickness 100 mm). First apply a suitable

fireproof layer/glue (e.g. Promastop-CC/fa. Promat)

onto the damper at the place of its future placement,

assemble and glue the filling of the future installation

with the same glue. After the glue has dried the damper

along with the filling are ready for installation.

3. Apply the same glue onto the internal surface of the wall

opening. Also apply the same glue on the external surface

of the filling glued on the damper surface. Immediately after

application place the damper into the wall opening in such

way that will not deform the damper housing.

The damper blade must be located in the supporting struc-

ture. Then fix the damper using the bendable bracket.

4. After inserting the damper into the opening and fixing it

using the bendable brackets (they determine the depth

of the damper’s placement into the wall) and suitable

screws (3; recommended screw diameter 5,5 - for example

DIN7981), apply the same fire resistant mastic (4), at least

2mm thick and 100 mm wide, on the opening filling and wall

edges evenly from both sides (adjacent duct must be covered

with the mastic too). Do not apply this layer in the place

where the mechanism is located, inspection openings and

manufacturer labels.

5. (Applies only to PKIS-EI90S)

It is necessary to fix the dampers installed into a wall using

four steel L-profiles (5; 60

×

40

×

3 mm) from above and

below. Anchor the profiles to the wall on each end using at

least one screw (6; recommended screw diameter 5,5 - for

example DIN7981) and self-drilling screws against the dam-

per with maximum 200 mm gaps (7; recommended screw

diameter 3,9

×

max.13 - for example DIN7504).

6. Dampers installed into a ceiling need to be fixed onto

the ceiling using two steel L-profiles (5; 60

×

40

×

3 mm)

from above (applies for all types). Anchor the profiles to the

ceiling on each end using at least one screw (6; recommen-

ded screw diameter 5,5 - for example DIN7981) and self-

drilling screws against

the damper with maximum 200 mm gaps (7; recommended

screw diameter 3,9

×

max.13 - for example DIN7504).

7. Before the glue dries, remove the unwanted remnants

of the glue.

8. If needed, uncover and clean the damper after installation.

9. Check the damper functionality.