OPERATION & MAINTENANCE MANUAL SWE18UF

56

4.2 MAINTENANCE GUIDE

4.2.1 Adding Lubricant Grease

Parts name

Qty.

Interval

(

hours

)

8

50

100

250

500

1000

2000

Each

junction

pin shaft of

working

device

Junction pin shaft of

boom and platform

1

▲

Pin shaft on two ends of

boom cylinder

2

▲

Each pin shaft of bucket

and arm

8

▲

Pin shaft on two ends of

dozer cylinder

2

▲

Junction pin shaft of

dozer blade and chassis

2

▲

Swing bearing track

1

▲

Inner swing gear ring

1

▲

Control lever

4

During maintenance

Position: bucket, arm, boom, slewing gear, slewing bearing, etc.

From —20 to 40

C

(

from —4 to 104F

)

BP petroleum

BP Energrease Ls—EP2

Caltex petroleum

Multifax EP2

Esso

Beacon EP2

Japan

Daphne Coronex Grease EP2

Mobil petroleum

Mobilux EP2

Germany

2# lithium grease

★

Shell

Shell Alvania EP Grease 2

Remark

Heavy duty lithium grease

Note

:

The excavator departed from factory has been filled with “★” marked engine

Содержание SWE18UF

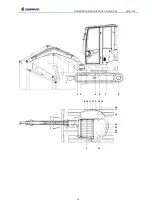

Страница 19: ...OPERATION MAINTENANCE MANUAL SWE18UF 13 Radius Lift point Lift height Swing center...

Страница 42: ...OPERATION MAINTENANCE MANUAL SWE18UF 36...

Страница 58: ...OPERATION MAINTENANCE MANUAL SWE18UF 52 3 4 5 6 7 8 1 2 9 10 11 14 16 19 20 18 17 15 13 12 21 22...

Страница 105: ...OPERATION MAINTENANCE MANUAL SWE18UF 99 8 APPENDIX 8 1 ELECTRICAL SCHEMATIC...

Страница 107: ...101 8 3 HYDRAULIC SCHEMATIC...

Страница 120: ...OPERATION MAINTENANCE MANUAL SWE18UF 114...