10

Hyponic®

Operating and Maintenance Manual

Hyponic® Operating and Maintenance Manual

11

www.SumitomoDrive.com

Note:

Customer should supply parts for setting, securing or removing the shaft.

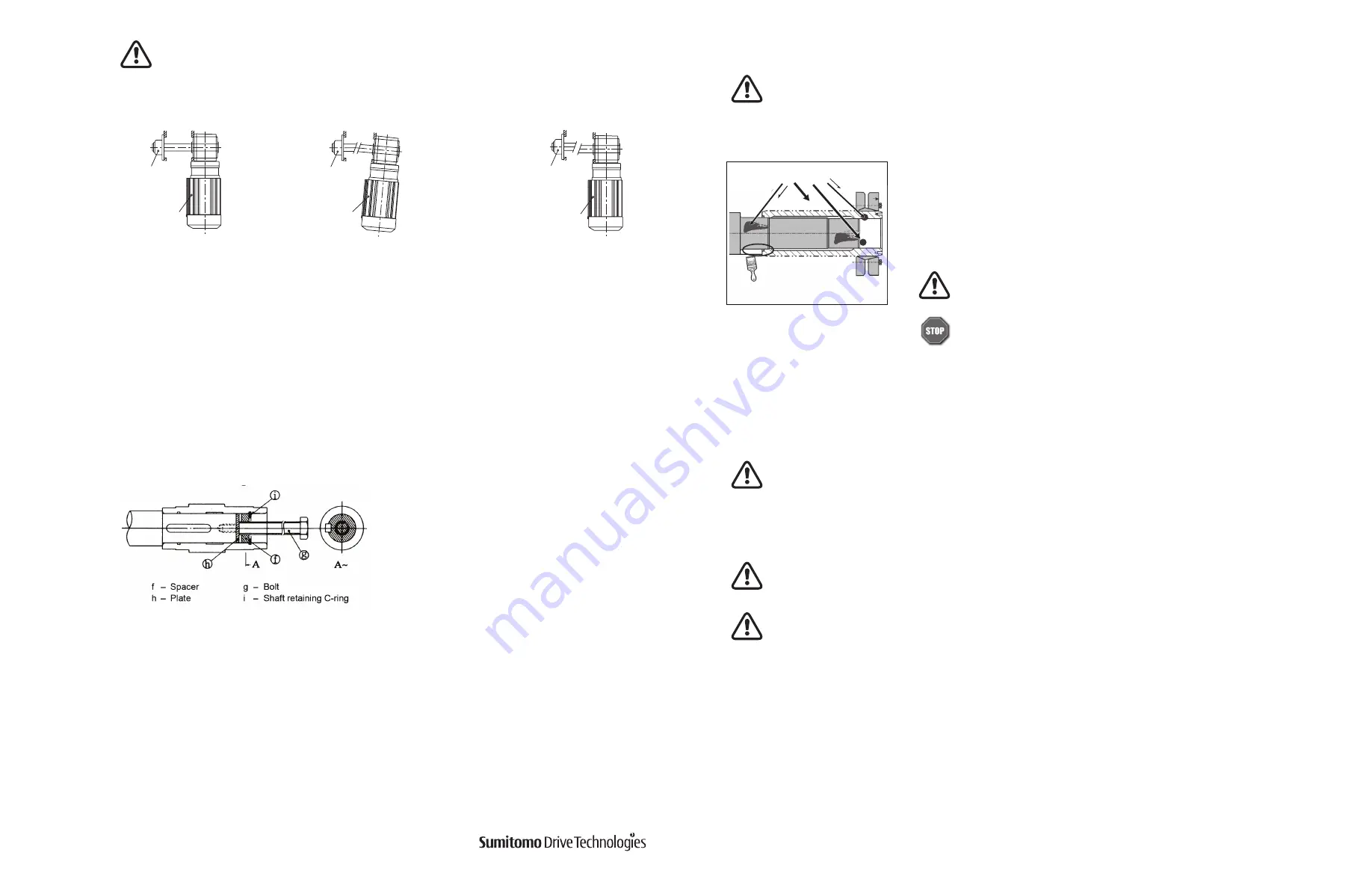

Fig. 9

When installing the gearmotor when flange-mounted, ensure that the gearmotor and the

shaft of the driven machine are properly aligned so that the gearmotor is free from excessive

force

(Figure 8)

.

Fig. 8

Hyponic® hollow

shaft model

Bearing unit

Poor concentricity of driven

shaft and mounting flange

Incorrect

Hyponic® hollow

shaft model

Bearing unit

Poor perpendicularity of driven shaft

center and mounting flange surface

Incorrect

Hyponic® hollow

shaft model

Bearing unit

Correct

Shrink Disc

1

Clean and degrease contact surfaces; reducer shaft and bore, and the machine

driven shaft.

Apply Molykote 321 or an equivalent dry film lubricant to the driven shaft

projection opposite from the shrink disc.

2

Align the driven shaft with the reducer hollow bore and carefully slide unit onto the driven shaft.

If the fit is tight, strike on the reducer hollow bore with a mallet to assist in the assembly.

If using a soft non-metallic mallet during installation, strike

only

against the unit’s steel hollow bore.

Do not

strike the reducer housing or oil seal. Damage to the bearings, the housing, and/or the seals may occur.

Note:

If the fit is tight, use a jig such as the one shown in

Figure 5

to ease assembly.

Sumitomo does not supply a

mounting jig. This information is provided for reference only.

Never tighten locking screws before shaft installation. Inner ring may become permanently contracted even

at low tightening torques.

Ensure that all power switches are locked out before installing or removing shrink disc. Wear safety glasses

and protective clothing at all times

Before placing unit onto driven shaft,

do not apply grease, oil, or anti-seize grease

to the entire driven

shaft or to the bore of the shrink disc. Use of these friction-minimizing products will adversely affect the

ability of the unit to transmit torque.

3

Remove any wooden spacers that may have been used during shipping. Lightly lubricate the hub outside diameter

and shrink disc bore.

Degrease these areas

Apply Molykote 321

to this shaft area only

For food grade application, use food grade dry film lubricant.

Do not apply any friction minimizing compound to the driven shaft at

or near the shrink disc

d.

Removing the Shaft

Do not apply excessive force to the unit and shaft. Using a jig as shown in

Figure 9

will facilitate

removal of the shaft.