4

Hyponic®

Operating and Maintenance Manual

Hyponic® Operating and Maintenance Manual

5

www.SumitomoDrive.com

Transportation

Ambient temperature:

Humidity:

Altitude:

Atmosphere:

14°F to 104°F

(-10°C to 40°C)

85% or less

Lower than 3300 ft (1000 m) above sea level

Free from corrosive gases, explosive gases or steam. It should also be free from dust and well

ventilated.

Do not stand directly under a unit suspended by a crane or other lifting mechanism; otherwise, injury or

death may result.

•

Exercise ample care so as not to drop the unit.

When a hanging bolt or hole is provided, be sure to use it. After mounting a unit to a machine, do not hoist the

entire machine using the hanging bolt or hole; otherwise, personal injury or damage to the equipment and/or

lifting device may result.

•

Before hoisting, refer to the rating plate, crate, outline drawing, catalog, etc. for the weight of the unit. Never hoist

a unit that exceeds the rating of the crane or other mechanism being used to lift it; otherwise, personal injury or

damage to the equipment and/or lifting device may result.

•

Use an appropriate hanging bolt or hole, and make sure that the eye-bolt and/or nut is not loose before hoisting.

•

Inspect the input shaft hollow bore and the motor shaft for debris or other material that may prevent the insertion

of the motor shaft into the hollow quill input shaft – carefully clean if necessary.

•

To enable easy installation and removal of the motor, apply anti-seize paste to both the reducer hollow bore and the

motor shaft.

•

Hollow input shaft units for the

Food and Beverage Industry

have either an o-ring or gasket material (solid or

liquid) for installation between the motor and reducer.

•

Place the motor key into the motor shaft and carefully insert the motor into the quill high-speed shaft of the

reducer. Do not force the assembly if the shafts are slanted or misaligned or if the key is only partially engaged.

•

Ensure that the motor flange bolts are aligned with the through holes of the reducer flange, and also ensure that the

motor is properly aligned with the reducer.

•

Bolt the motor into place. Refer to the motor operating instructions for proper bolt tightening torque.

Important:

If

the bolt is tightened when the fitting is not inserted, uneven tightening will result, causing damage to the internal

bearing and other components.

•

After wiring the motor as recommended in the Wiring section, the motor shaft rotates to the right as seen from

the fan cover side.

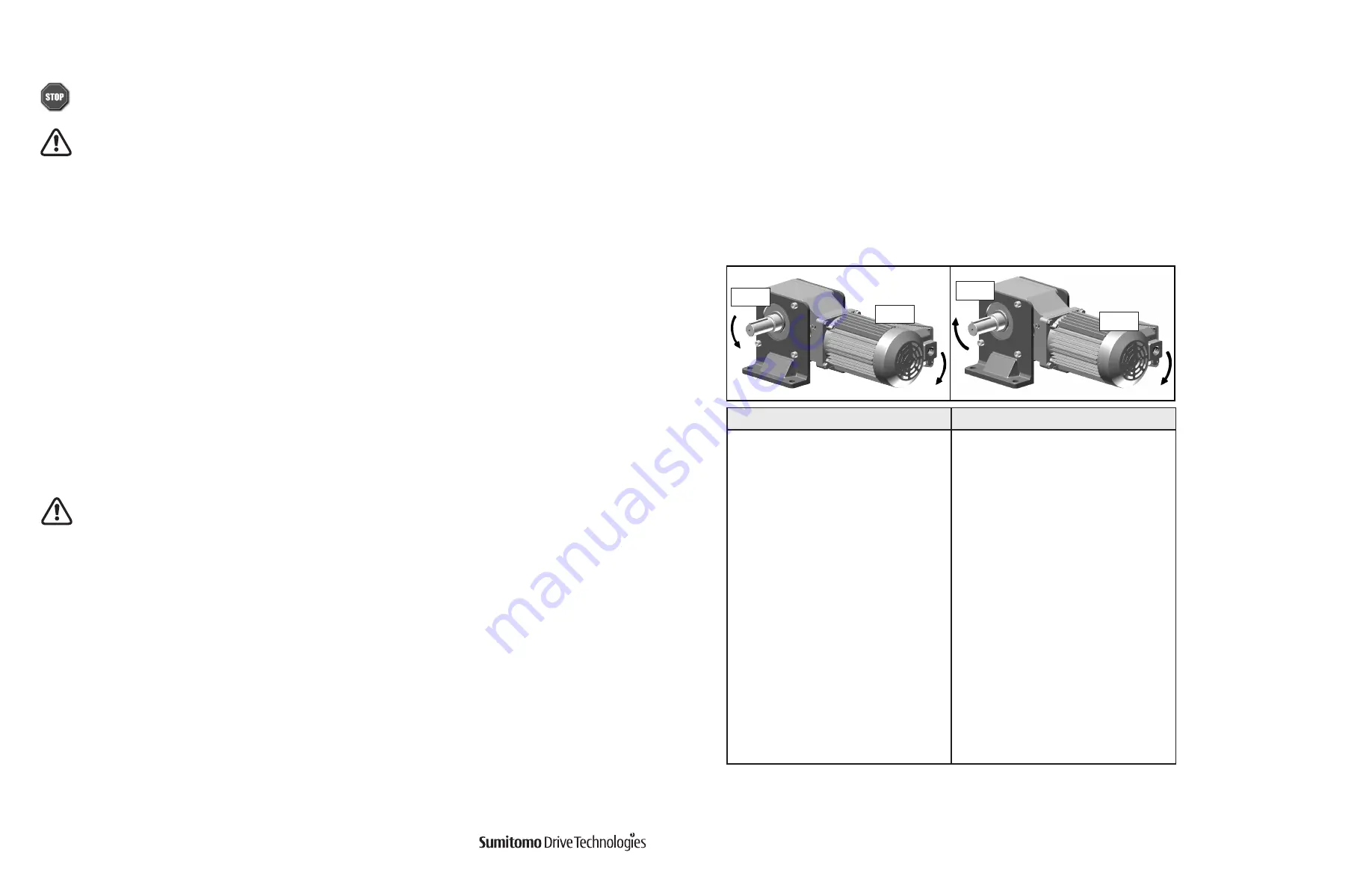

Figure 1

shows the direction of rotation for the output shaft depending on the size and ratio

combination.

•

After corroborating direction of rotation, the gearmotor can be connected to the driven machine. It is

recommended to do a test run with no load, and increase load gradually. Observe precautions listed in

Table 8

Trial

Run Precautions in the Operation section during test run.

Installation

Standard Operating Conditions

Mounting Angle

Motor Mounting (Quill Input Shaft)

Direction of Rotation

There is no limit on a mounting angle.

Do not remove the motor’s eye-bolt. In the rare case that it is removed, insert a bolt or other appropriate material

into the screw hole to prevent water or other substances from entering the motor through the screw hole.

Reducer Supplied with Motor (assembled):

Some units may come from the factory with the motor attached. In this case, no additional preparation is required.

Customer Supplied Motor or Motor Supplied Separately (disassembled):

Note:

Swapping two of the three input power leads of a three-phase induction motor will cause the motor direction to reverse.

Model

Counter Clockwise Reduction Ratio (:1)

Model

Clockwise Reduction Ratio (:1)

1120

5, 7, 10, 12, 15, 20, 25, 30, 40, 50, 60

1120

–

1220

5, 7, 10, 12, 15, 20, 25, 30, 40, 50, 60

1220

–

1230

–

1230

80, 100, 120, 150, 200, 240

1320

5, 7, 10, 12, 15, 20, 25, 30, 40, 50, 60

1320

–

1330

–

1330

80, 100, 120, 150, 200, 240

1340

300, 360, 480, 600, 720, 900, 1200, 1440

1340

–

1420

5, 7, 10, 12, 15, 20, 25, 30, 40, 50, 60

1420

–

1430

–

1430

80, 100, 120, 150, 200, 240

1440

300, 360, 480, 600, 720, 900, 1200, 1440

1440

–

1520

5, 7, 10, 12, 15, 20, 25, 30, 40, 50, 60

1520

–

1521

5, 7, 10, 12, 15, 20, 25

1521

–

1522

5, 7, 10, 12, 15

1522

–

1530

–

1530

80, 100, 120, 150, 200, 240

1531

–

1531

40, 50, 60, 80

1540

300, 360, 480, 600, 720, 900, 1200, 1440

1540

–

1630

10, 12, 15, 20, 25, 30, 40, 50

1630

60, 80, 100, 120

1631

–

1631

150, 200, 240

1632

10, 12, 15, 20, 25, 30

1632

40, 50, 60

1633

20, 25

1633

30, 40

1634

5, 7, 10, 12, 15

1634

20, 25

1640

300, 360, 480, 600, 720, 900, 1200, 1440

1640

–

Fig. 1 Rotating Direction of the Output Shaft

CCW

CW

CW

CW