18

Hyponic®

Operating and Maintenance Manual

Hyponic® Operating and Maintenance Manual

19

www.SumitomoDrive.com

Operation

Once the Hyponic® unit is installed, ensure that the wiring is correct and secure prior to operation. Observe the

precautions listed in

Table 8

during the trial run. Stop running the gearmotor if any abnormalities are detected and

contact your nearest sales office or distributor.

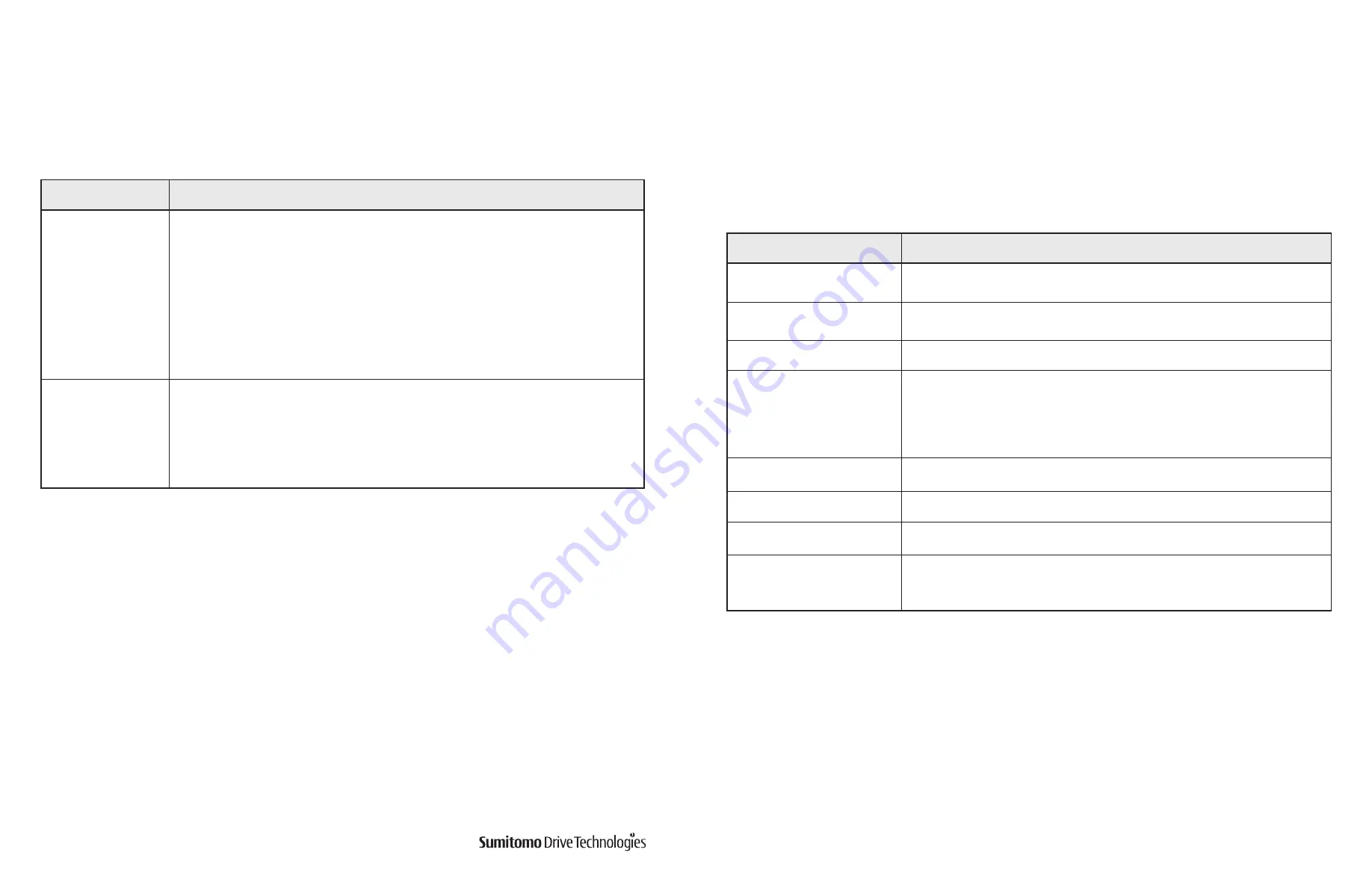

Observation

Possible Cause

Any abnormal

noises or

vibrations

1. The casing is distorted due to an uneven mounting surface.

2. The gearmotor is resonant due to insufficient rigidity of the mounting surface.

3. The shaft of the Hyponic® and the driven machine are not aligned.

4. Vibrations of the driven machine are conveyed to the gearmotor.

5. Rigidity of the driven machine and its shaft is insufficient (hollow shaft type).

6. Excessive force is exerted on the baffle sections of the torque arm (hollow shaft

type).

7. After the Hyponic® unit is flange or foot mounted, undue force is exerted between

the gearmotor and its shaft.

Abnormally high

temperature of

the gear casing

or motor frame

surface.

1. Motor electric current is exceeding the rated value specified on the nameplate.

2. Is voltage applied between THREE motor connections equal to the motor

nameplate voltage rating ± 10%?

3. The ambient temperature around the unit is too high.

Table 8. Trial Run Precautions

Daily Inspection and Maintenance

1.

Inspect the gearmotor daily for each of the items listed in

Table 9

.

2.

If any abnormalities are found during daily inspections, follow the procedures outlined in the Troubleshooting

Guide,

Table 18 on page 32

. If the abnormality is not listed or the recommended procedure does not solve the

problem, contact your nearest sales office or distributor.

3.

The Hyponic® unit does not require grease replenishment, but overhauling after 20,000 hours of operation, or 3 -

5 years will extend its life.

Items

Details

Electric Current

Is the electric current higher than the value specified on the nameplate?

Noise

Is the gearmotor making any unusual sounds?

Vibration

Are there any unusual vibrations of the gear or motor frame?

Surface Temperature

Is the surface temperature of the gear case, or motor frame too high or rising

suddenly? (The temperature rise during operation varies depending on the

type of motor. There may be a problem, if the temperature frequently rises

approximately 40°C (104°F) above the ambient temperature.)

Grease Leakage

Is there any grease leaking from the gear assembly?

Mounting Bolts/Torque Arm

Are there any loose mounting bolts?

Chains and V-belts

Are there any loose chains or V-belts?

Brake

Is the brake lining worn out?

Is the air gap within specification?

Table 9. Daily Inspection Items