SECTION 6

TS32 USER MANUAL

75

6.8

TROUBLESHOOTING—

INTRODUCTION

The information contained in the Troubleshooting

Guide has been compiled from field report data and

factory experience. It contains symptoms and usual

causes for the described problems. However, DO

NOT assume that these are the only problems that

may occur. All available data concerning a problem

should be systematically analyzed before

undertaking any repairs or component replacement

procedures.

In addition to the Troubleshooting Guide, consult the

Supervisor Controller manual for additional

troubleshooting guidelines pertaining to the

Supervisor Controller.

A detailed visual inspection is worth performing for

almost all problems and may avoid unnecessary

additional damage to the compressor. Always

remember to:

1. Check for loose wiring.

2. Check for damaged piping.

3. Check for parts damaged by heat or an elec-

trical short circuit, usually apparent by discol-

oration or a burnt odor.

Should your problem persist after making the

recommended check, consult your nearest Sullair

representative.

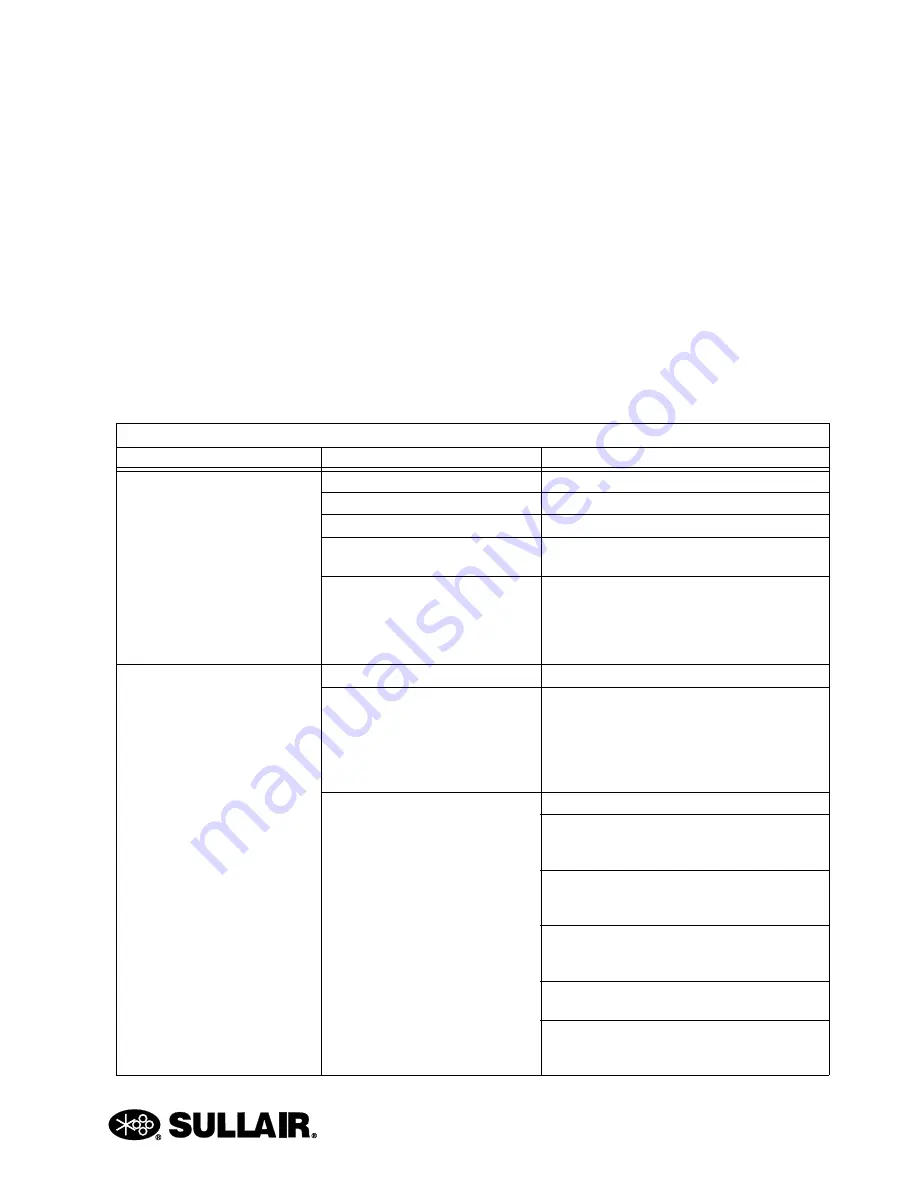

Table 6-2: Troubleshooting Guide

SYMPTOM

PROBABLE CAUSE

REMEDY

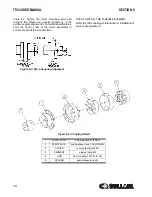

Compressor will not start

Main disconnect switch open

Close switch.

Line fuse blown

Replace fuse.

Control Transformer Fuse Blown

Replace fuse.

Motor Starter Overloads Tripped

Reset. Should trouble persist, check whether

motor starter contacts are functioning properly.

Low Incoming Line Voltage

Check voltage. Should voltage check low,

consult power company.

Replace Supervisor display module if no

display or erratic display.

Compressor Shuts Down With

Air Demand Present

Loss of control voltage

Check incoming power.

Low incoming voltage

Check control fuses and wiring.

Consult power company. The Sullair

Supervisor will provide indication of most

maintenance problems if control power has not

been lost. Shutdowns will occur upon a faulty

condition or a bad sender condition.

Excessive operating pressure

Check maximum P2 pressure setting.

HIGH PRESS P1 display; Max P1 pressure

may be set too low. Consult factory for

recalibration.

Defective solenoid valve; solenoid valve

should cause inlet to unload when unload

pressure is exceeded. Repair if defective.

Defective blowdown valve; blowdown valve

should open when in the unload mode. Repair

if defective.

Open or shorted P1, P2, P3 or P4 sender

message; replace sender indicated.

Operating lever of inlet butterfly valve is loose

on valve shaft. Reposition the valve plate and

tighten lever set screw.

Содержание TS32 AC

Страница 10: ...NOTES 10...

Страница 12: ...TS32 USER MANUAL SECTION 2 12 Figure 2 1 Sullair Series TS32 Rotary Screw Compressor Air cooled Typical...

Страница 13: ...SECTION 2 TS32 USER MANUAL 13 Figure 2 2 Sullair Series TS32 Rotary Screw Compressor Water cooled Typical...

Страница 15: ...SECTION 2 TS32 USER MANUAL 15 Figure 2 3 Compressor Piping and Instrument Diagram Typical...

Страница 16: ...TS32 USER MANUAL SECTION 2 16 Figure 2 4 Compressor Cooling and Lubrication System Air cooled...

Страница 17: ...SECTION 2 TS32 USER MANUAL 17 Figure 2 5 Compressor Cooling and Lubrication System Water cooled...

Страница 18: ...TS32 USER MANUAL SECTION 2 18 Figure 2 6 Compressor Discharge System Air cooled 200 350HP...

Страница 19: ...SECTION 2 TS32 USER MANUAL 19 Figure 2 7 Compressor Discharge System Water cooled 200 350HP...

Страница 20: ...TS32 USER MANUAL SECTION 2 20 Figure 2 8 Control System START Typical...

Страница 21: ...SECTION 2 TS32 USER MANUAL 21 Figure 2 9 Control System MODULATION Typical...

Страница 22: ...TS32 USER MANUAL SECTION 2 22 Figure 2 10 Control System UNLOAD Typical...

Страница 23: ...SECTION 2 TS32 USER MANUAL 23 Figure 2 11 Control System FULL LOAD Typical...

Страница 26: ...TS32 USER MANUAL SECTION 2 26 Figure 2 12 Compressor Air Inlet System...

Страница 30: ...TS32 USER MANUAL SECTION 3 30 Figure 3 2 Identification Air Cooled 02250126 376 R02...

Страница 32: ...TS32 USER MANUAL SECTION 3 32 Figure 3 2 Identification Water Cooled 02250126 378 R03...

Страница 34: ...TS32 USER MANUAL SECTION 3 34 Figure 3 3 Piping and Instrumentation Diagram Air Cooled 02250179 499 R01...

Страница 38: ...TS32 USER MANUAL SECTION 3 38 Figure 3 5 Piping and Instrumentation Diagram Remote Air Cooled 02250179 498 R01...

Страница 42: ...TS32 USER MANUAL SECTION 3 42 Figure 3 6 Piping and Instrumentation Diagram Water Cooled 02250179 496 R01...

Страница 46: ...TS32 USER MANUAL SECTION 3 46 Figure 3 7 Wiring Diagram Water Cooled Wye Delta 02250178 841 R01...

Страница 48: ...TS32 USER MANUAL SECTION 3 48 Figure 3 8 Wiring Diagram Air Cooled Full Voltage 02250178 845 R01...

Страница 50: ...TS32 USER MANUAL SECTION 3 50 Figure 3 9 Wiring Diagram Air Cooled SSRV 02250178 844 R03...

Страница 52: ...TS32 USER MANUAL SECTION 3 52 Figure 3 10 Wiring Diagram Remote Air Cooled Wye Delta 02250178 836 R01...

Страница 54: ...NOTES 54...

Страница 78: ...NOTES 78...

Страница 79: ...NOTES 79...