TS32 USER MANUAL

SECTION 2

14

After the air/fluid mixture is discharged from the

compressor unit, the fluid is separated from the air.

At this time, the air flows to the service line and the

fluid is cooled in preparation for re-injection.

The fluid also serves as lubricant for the anti-friction

bearings and the drive gear sets.

2.3

COMPRESSOR COOLING

AND LUBRICATION

SYSTEM, FUNCTIONAL

DESCRIPTION

through

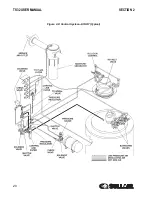

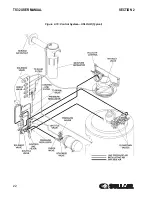

. The cooling

and lubrication system (air-cooled version) consists

of a fan, radiator-type cooler/aftercooler assembly,

full-flow main line filter, thermal valve and

interconnecting piping.

For the water-cooled models, a shell and tube fluid

cooler, and aftercooler are substituted for the

radiator- type cooler on air-cooled compressors. The

pressure in the separator/sump tank causes fluid

flow by forcing the fluid from the high pressure area

of the sump to an area of lower pressure in the

compressor unit.

Fluid flows from the bottom of the separator/sump

tank to the thermal valve. The thermal valve is fully

open to the compressor unit when the fluid

temperature is below 185ºF (85ºC). The fluid passes

through the thermal valve, the main filter and directly

to the compressor unit where it lubricates, cools and

seals the rotors and the compression chamber.

As the discharge temperature rises above 185ºF

(85ºC), due to the heat of compression, the thermal

valve begins to close and a portion of the fluid then

flows through the cooler. From the cooler, the fluid

flows to the main filter and on to the compressor unit.

The filter has a replacement element and an integral

pressure bypass valve. When the element pressure

exceeds 20 psid (1.4 bar), the filter begins to bypass.

The Supervisor monitors the filter pressure drop and

displays a maintenance requirement message.

A fluid stop valve is also present in the lubrication

circuit. The fluid stop valve prevents fluid from filling

the compressor unit when the compressor is shut

down. When the compressor is operating, the fluid

stop valve is held open by air pressure from the

compressor unit allowing a free flow of fluid from the

separator/sump tank back to the compressor unit. On

shutdown, the compressor unit pressure is reduced,

causing the fluid stop valve to close and isolate the

compressor unit from the cooling system.

Water-cooled models have a water pressure switch

to prevent operation with inadequate water pressure.

2.4

COMPRESSOR DISCHARGE

SYSTEM, FUNCTIONAL

DESCRIPTION

,

and

. The

compressor unit discharges the compressed air/fluid

mixture into the combination separator/sump tank.

The separator/sump tank has three functions:

• It acts as a primary fluid separator.

• Serves as the compressor fluid sump.

• Houses the final fluid separator elements.

The compressed air/fluid mixture enters the

separator/sump tank and is directed through a

centrifugal baffle. Through centrifugal action and a

velocity reduction large droplets of fluid form and fall

to the bottom of the separator/sump tank. The

fractional percentage of fluid remaining in the

compressed air collects on the surface of the dual

separator elements as the compressed air flows

through them. Two return lines (or scavenge tubes)

lead from the bottom of each separator element to

the low pressure region of the compressor unit. Fluid

collecting on the bottom of each separator is returned

to the compressor by a pressure difference between

the separator/sump tank and the compressor inlet.

Sight glasses are located in the return lines to

observe this fluid flow. There are also orifices

(protected by strainers) within the sight glasses to

assure proper flow. When the total pressure drop

across the elements exceeds 10 psid (0.7 bar), the

Supervisor displays a maintenance requirement

message.

The separator/sump tank is a pressure vessel

designed and built to codes administered by

appropriate governing bodies. A combination

minimum pressure/check valve, located downstream

from the separator, assures a minimum separator/

sump tank pressure of 50 psig (3.5 bar) during all

conditions. This pressure is necessary for proper air/

fluid separation and proper fluid circulation while

supplying air to the system. This valve also acts as a

check valve preventing compressed air in the service

line from bleeding back into the separator/sump tank

on shutdown and during operation on the

compressor in an unloaded condition.

NOTE

Standard thermal valve temperature is

175ºF/79ºC (operating temperature of 180ºF/

82ºC). Thermal valve temperature is 190ºF/

88ºC (operating temperature of 195ºF/ 91ºC)

for HH, XH and 24KT machines.

Содержание TS32 AC

Страница 10: ...NOTES 10...

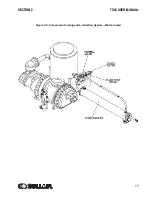

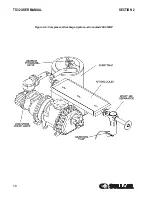

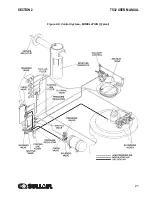

Страница 12: ...TS32 USER MANUAL SECTION 2 12 Figure 2 1 Sullair Series TS32 Rotary Screw Compressor Air cooled Typical...

Страница 13: ...SECTION 2 TS32 USER MANUAL 13 Figure 2 2 Sullair Series TS32 Rotary Screw Compressor Water cooled Typical...

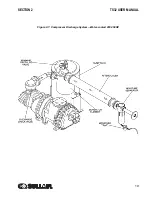

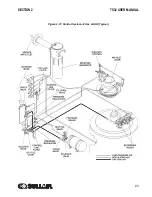

Страница 15: ...SECTION 2 TS32 USER MANUAL 15 Figure 2 3 Compressor Piping and Instrument Diagram Typical...

Страница 16: ...TS32 USER MANUAL SECTION 2 16 Figure 2 4 Compressor Cooling and Lubrication System Air cooled...

Страница 17: ...SECTION 2 TS32 USER MANUAL 17 Figure 2 5 Compressor Cooling and Lubrication System Water cooled...

Страница 18: ...TS32 USER MANUAL SECTION 2 18 Figure 2 6 Compressor Discharge System Air cooled 200 350HP...

Страница 19: ...SECTION 2 TS32 USER MANUAL 19 Figure 2 7 Compressor Discharge System Water cooled 200 350HP...

Страница 20: ...TS32 USER MANUAL SECTION 2 20 Figure 2 8 Control System START Typical...

Страница 21: ...SECTION 2 TS32 USER MANUAL 21 Figure 2 9 Control System MODULATION Typical...

Страница 22: ...TS32 USER MANUAL SECTION 2 22 Figure 2 10 Control System UNLOAD Typical...

Страница 23: ...SECTION 2 TS32 USER MANUAL 23 Figure 2 11 Control System FULL LOAD Typical...

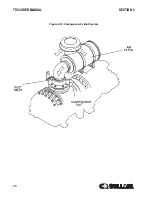

Страница 26: ...TS32 USER MANUAL SECTION 2 26 Figure 2 12 Compressor Air Inlet System...

Страница 30: ...TS32 USER MANUAL SECTION 3 30 Figure 3 2 Identification Air Cooled 02250126 376 R02...

Страница 32: ...TS32 USER MANUAL SECTION 3 32 Figure 3 2 Identification Water Cooled 02250126 378 R03...

Страница 34: ...TS32 USER MANUAL SECTION 3 34 Figure 3 3 Piping and Instrumentation Diagram Air Cooled 02250179 499 R01...

Страница 38: ...TS32 USER MANUAL SECTION 3 38 Figure 3 5 Piping and Instrumentation Diagram Remote Air Cooled 02250179 498 R01...

Страница 42: ...TS32 USER MANUAL SECTION 3 42 Figure 3 6 Piping and Instrumentation Diagram Water Cooled 02250179 496 R01...

Страница 46: ...TS32 USER MANUAL SECTION 3 46 Figure 3 7 Wiring Diagram Water Cooled Wye Delta 02250178 841 R01...

Страница 48: ...TS32 USER MANUAL SECTION 3 48 Figure 3 8 Wiring Diagram Air Cooled Full Voltage 02250178 845 R01...

Страница 50: ...TS32 USER MANUAL SECTION 3 50 Figure 3 9 Wiring Diagram Air Cooled SSRV 02250178 844 R03...

Страница 52: ...TS32 USER MANUAL SECTION 3 52 Figure 3 10 Wiring Diagram Remote Air Cooled Wye Delta 02250178 836 R01...

Страница 54: ...NOTES 54...

Страница 78: ...NOTES 78...

Страница 79: ...NOTES 79...