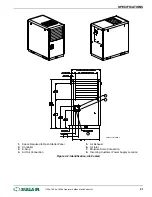

4.1 MOUNTING OF COMPRESSOR

A suitable foundation or fabricated support must be

established to support the compressor. It should be rigid

enough to keep the compressor frame level and maintain

alignment of the compressor and motor. Tie-down bolts of

sufficient size must be used to provide uniform contact

between the foundation and the compressor frame.

Materials such as rubber or cork can be used to provide

uniform contact between the foundation and compressor

frame.

•

Piping loads must be eliminated through the use of flex

connectors or other systems which prevent piping

loads from being transmitted to the compressor.

•

Special consideration should be made to meet

national and local electrical codes for the required

space around and in front of the electrical panel.

Lighting should be provided for future service

requirements.

•

Accessibility for fork lift trucks, overhead cranes and

maintenance vehicles should be given careful

consideration in order to provide any maintenance

that may be required. Adequate space around the unit

should be provided for access to all components of the

compressor.

•

Softer surfaces in walls or ceilings will absorb sound

and minimize ambient noise levels. Harder, reflective

surfaces will increase ambient noise levels.

NOTE

Ambient temperatures above 104˚F

(40˚C) require that the high ambient

option is specified for the

compressor.

4.2 VENTILATION AND COOLING

Air-Cooled Compressors

•

An area with adequate space must be provided for the

compressor and its components. Air-cooled

compressors require a minimum of 3 feet (1 meter)

around the perimeter of the compressor.

•

The location should be free from standing water and

allow access to clean air that is free from exhaust and

paint fumes, dust, metal filings or caustic chemicals.

•

Cooling air should be removed from the area in order

to prevent the re-introduction of heated exhaust air

back into the compressor’s cooling system.

•

Reduced headroom above the compressor will

require that cooling air be either ducted or in some way

deflected away from the compressor. Inadequate

ventilation will result in higher ambient operating

temperatures.

NOTE

Systems that employ both a

conventional reciprocating

compressor and a screw-type axial

compressor must be isolated from

each other by use of a common

receiver tank. Individual airlines from

each compressor should be piped to

the common receiver tank.

NOTE

Shipping straps are painted red in

order to help identify them for

removal. Be sure to remove them prior

to operation of the compressor.

®

SULLAIR

®

Section 4

INSTALLATION

®

SULLAIR

®

1100e, 1500e, 1800e Operator’s Manual and Parts List

31

Содержание 1107e

Страница 13: ...THIS PAGE INTENTIONALLY LEFT BLANK DESCRIPTION SULL AIR 1100e 1500e 1800e Operator s Manual and Parts List 9...

Страница 34: ...SECTION 3 THIS PAGE INTENTIONALLY LEFT BLANK 30 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 42: ...SECTION 5 THIS PAGE INTENTIONALLY LEFT BLANK 38 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 50: ...SECTION 6 THIS PAGE INTENTIONALLY LEFT BLANK 46 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

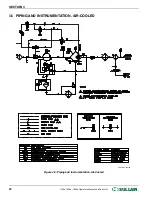

Страница 58: ...7 4 AIR INLET SYSTEM 02250157_200r02 SECTION 7 54 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 62: ...7 6 FLUID PIPING 02250154 767R003 SECTION 7 58 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 68: ...7 9 MOISTURE DRAIN 02250157_143R00 SECTION 7 64 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

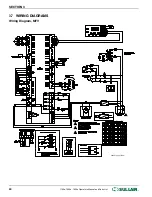

Страница 84: ...7 14 ENCLOSURE 02250155_649R05 SECTION 7 80 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 100: ...SECTION 7 THIS PAGE INTENTIONALLY LEFT BLANK 96 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 101: ...THIS PAGE INTENTIONALLY LEFT BLANK...