2.5 COMPRESSOR DISCHARGE

SYSTEM, FUNCTIONAL

DESCRIPTION

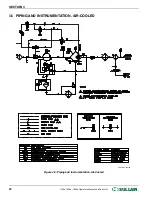

Refer to Figure 2-3. The compressor unit discharges the

compressed air/fluid mixture into the combination receiver

tank.

The receiver tank has three basic functions:

1. It acts as a primary fluid separator.

2. Serves as the compressor fluid receiver tank.

3. Houses the final fluid separator.

The compressed air/fluid mixture enters the receiver tank

and flows through an internal baffle system. The direction

of movement is changed and its velocity significantly

reduced, thus causing large droplets of fluid to form and

fall to the bottom of the receiver tank. The fractional

percentage of fluid remaining in the compressed air

collects on the surface of the separator element as the

compressed air flows through the separator. A return line

(or scavenge tube) leads from the bottom of the separator

element to a medium pressure region of the compressor

unit. Fluid collecting on the bottom of the separator is

returned to the compressor by a pressure differential

between the receiver tank and the compressor. A visual

sight glass is located on the return line to observe this fluid

flow. There is also an orifice in this return line (protected

by a strainer) to assure proper flow. The separator system

reduces the fluid carry-over to less than 1 ppm (parts per

million) for Sullube or 2 ppm for 24KT. A message on the

controller indicates if abnormal pressure drop through the

separator develops. At this time, separator element

replacement is necessary.

A minimum pressure/check valve, located downstream

from the separator, assures a minimum receiver tank

pressure of 50 psig (3.4 bar) during loaded conditions.

This pressure is necessary for proper air/fluid separation

and proper fluid circulation.

A terminal check valve is incorporated into the minimum

pressure/check valve to prevent compressed air in the

service line from bleeding back into the receiver tank on

shutdown and during operation of the compressor in an

unloaded condition.

A pressure relief valve (located on the wet side of the

separator) is set to open if the receiver tank pressure

exceeds the receiver tank rating. A temperature switch will

shut down the compressor if the discharge temperature

reaches 235˚F (113˚C).

WARNING

DO NOT remove caps, plugs, and/or

other components when compressor

is running or pressurized.

Stop compressor and relieve all

internal pressure before doing so.

Fluid is added to the receiver tank via a capped fluid filler

opening, placed on the inlet housing to prevent overfilling

of the receiver tank. A sight glass enables the operator to

visually monitor the receiver tank fluid level.

SECTION 2

10

1100e, 1500e, 1800e Operator’s Manual and Parts List

®

SULLAIR

®

Содержание 1107e

Страница 13: ...THIS PAGE INTENTIONALLY LEFT BLANK DESCRIPTION SULL AIR 1100e 1500e 1800e Operator s Manual and Parts List 9...

Страница 34: ...SECTION 3 THIS PAGE INTENTIONALLY LEFT BLANK 30 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 42: ...SECTION 5 THIS PAGE INTENTIONALLY LEFT BLANK 38 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 50: ...SECTION 6 THIS PAGE INTENTIONALLY LEFT BLANK 46 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 58: ...7 4 AIR INLET SYSTEM 02250157_200r02 SECTION 7 54 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 62: ...7 6 FLUID PIPING 02250154 767R003 SECTION 7 58 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 68: ...7 9 MOISTURE DRAIN 02250157_143R00 SECTION 7 64 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 84: ...7 14 ENCLOSURE 02250155_649R05 SECTION 7 80 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 100: ...SECTION 7 THIS PAGE INTENTIONALLY LEFT BLANK 96 1100e 1500e 1800e Operator s Manual and Parts List SULL AIR...

Страница 101: ...THIS PAGE INTENTIONALLY LEFT BLANK...