Accutom-50

Instruction Manual

53

3.

Consumables

Please refer to the Selection Guide in the Struers

Accutom-50 accepts cut-off wheels with a diameter of 75 mm

(smallest flange is ø42 mm) up to 152 mm. Hole 12.7 mm.

Use the following table to select proper wheel and cutting parameters

according to the sample material.

Recommended Cutting Parameters

Material

Hardness

Force limit Feed

speed

[mm/s]

Wheel speed

[rpm]*)

Ceramics, minerals and

crystals

> HV 800

LOW

0.005-0.15 5000

LOW

0.005-0.20 4000

HIGH

0.005-0.30 3200

HIGH

0.005-0.30 2700

Sintered carbides and

hard ceramics

> HV 800

MEDIUM

0.005-0.25 3200

MEDIUM

0.005-0.25 2700

Extremely hard ferrous

metals

> HV 500

MEDIUM

0.005-0.25 5000

Hard and very hard

ferrous metals

HV 350-800

MEDIUM

0.05-0.30

1000-5000

MEDIUM

0.05-0.30

1000-5000

Hard and very hard

ferrous metals with larger

dimensions

HV 350-800

MEDIUM

0.05-0.30

1000-5000

Soft and medium soft

metals

HV 30-350

MEDIUM

0.05-0.30

1000-5000

MEDIUM

0.05-0.30

1000-5000

Soft and ductile non

ferrous metals

HV 70-400

MEDIUM

0.05-0.30

1000-5000

Plastics and very soft

metals

< HV 100

MEDIUM

0.05-0.30

max. 1200

*)

To obtain low wheel wear and better surface quality, always use highest recommended

wheel speed.

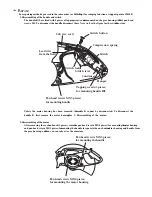

Cut-off Wheels

IMPORTANT!

Always use large flanges (65 mm) for the highest possible accuracy.

Optimising the Cutting Results

Cutting Parameters

Содержание Accutom-50

Страница 1: ...Manual No 15017001 Date of Release 15 11 2012 Accutom 50 Instruction Manual...

Страница 66: ...Accutom 50 Gebrauchsanweisung Handbuch Nr 15017001 Auslieferungsdatum 15 11 2012...

Страница 133: ...Accutom 50 Mode d emploi Mode d emploi no 15017001 Date de parution 15 11 2012...

Страница 199: ...Manual No 15017001 Date of Release 15 11 2012 Accutom 50 Spare Parts and Diagrams...

Страница 204: ......

Страница 205: ......

Страница 206: ......

Страница 207: ......

Страница 208: ......

Страница 209: ......

Страница 210: ......