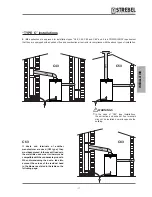

When the appliance is installed on systems that are old or to be updated, ensure that:

- The flue duct, if re-used, is suitable for the new condensing boiler, and that it is calculated and constructed in compliance

with current standards, as straight as possible, airtight, insulated and free of any obstructions or narrowed sections.

- The flue is fitted with an outlet for removal of condensate.

- The electrical system complies with the relevant standards and is set up by professionally qualified personnel.

- The fuel intake line and tank (if fitted) is produced according to the specific standards and is fitted with a gas meter.

- The expansion vessel ensures total absorption of fluid expansion in the system.

- The system is washed, removing all sludge and deposits and that all hydraulic seals are efficient.

- A supply water treatment/replenishment system is fitted, as described in the next chapter.

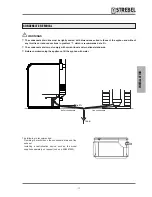

- Efficient systems are fitted for the elimination of air and impurities up to 5 μm (e.g. Y filters, micro-impurity

separators and micro air bubble separators).

- if an automatic filling system is fitted, a litre counter is installed in order for a precise check on the entity of any leaks.

- Water must never be drained from the system during routine maintenance, even in apparently insignificant quantities. For

example when cleaning filters, ensure that the system has specific shut-off valves for this purpose.

(*) The manufacturer declines all liability for possible damage caused by incorrect installation or design of the flue

or constant replenishment of water in the heating unit.

Before installing the appliance, thoroughly clean all pipelines and heating elements.

PROPERTIES OF WATER TO BE USED WHEN FILLING THE SYSTEM

The following type of water must be used to fill the system:

pH :

from 6.5 to 8.5 (presence of aluminium)

Ca+++ Mg++ : less than 0.5°f

OH- + 1/2 Ca3- : from 5 to 15°f

P

2

O

5

:

from 10 to 30 mg/l

Na

2

SO

3

:

from 20 to 50 mg/l

If the analysis of a sample of the water to be used for filling the system shows values other than those above, a suitable

inhibitor must be used. This will prevent the formation of scale, which could impair correct operation of the boiler unit.

In the case of systems at low temperatures only, a product must be used to inhibit the spread of bacteria.

Water treatment in civil heating systems: see standard UNI 8065 of 1989.

REPAIRS AND PARTS REPLACED DUE TO THE FORMATION OF SCALE ARE NOT COVERED BY THE WARRANTY.

CAUTION: both on new systems or replacements, the system must be fitted with efficient systems that eliminate the air

and impurities up to 5 μm (e.g. Y filters, micro impurity separators and micro air bubble separators).

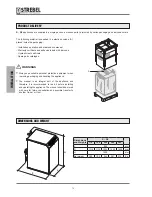

NEW INSTALLATIONS OR REPLACEMENTS OF OLDER APPLIANCES

WATER TREATMENT

- 18

-

INST

ALLA

TION