The aluminium heating units in the range S - AF are condensing heat generators, designed to heat rooms, and in

combination with a storage tank, for the production of domestic hot water.

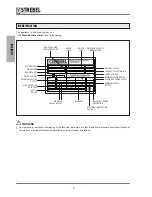

They comprise:

- an aluminium heat exchanger, with low water content and generously sized exchange surface to optimise energy

efficiency and heating output;

- a full pre-mix microflame burner in stainless steel, to guarantee high modulation ratios, combustion stability and low

pollutant emissions (NOx Class = 5);

- a variable speed blower, required for air/gas modulation and mixing;

- a combustion circuit, which can be “type C” (room-sealed) or “type B” (open-flued), with respect to the installation

environment, and on the basis of the flue exhaust configuration on site;

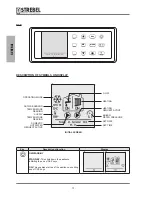

- command-control electronics, which if equipped with outside sensor enables adjustment of the supply temperature on

the basis of the outside temperature. The appliance thus only provides the heat effectively needed by the utility, avoiding

energy waste. The unit is fitted with self-diagnostics with a display of the error codes and operating parameters at the

time of the fault, thereby simplifying tasks for the Technical Services department.

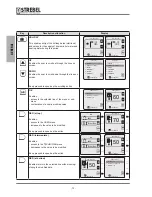

Also, during periods of prolonged disuse or holidays, the appliance remains protected by the Anti-freeze Function, which is

activated automatically when the supply temperature falls to 5°C and shuts off when it returns to 15°C. Obviously the gas

and electrical mains supplies must be active during these periods.

The design phase adopted specific solutions to:

- obtain a constantly optimal air/gas mix;

- minimise dispersions;

- reduce noise levels to a minimum.

The S - AF heating units are designed for connection to 0-10 V DC controls and for operation in cascade, in sets of up to 6

units, and can be equipped with various system accessories, such as the mix bottle or water shut-off valve, and the ISPESL

unit, which all simplify the work of the installer and comply with compulsory italian legal requirements.

DESCRIPTION

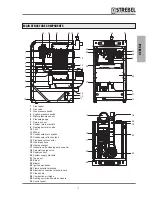

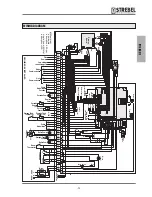

S - AF appliances are equipped with the following safety, control and adjustment devices:

- Sensor on the appliance heat exchanger, to ensure thermal cut-out when the temperature reading exceeds the maximum

admissible value. This is reset manually via the DSP keypad.

- Water pressure sensor: this intervenes when the hydraulic circuit pressure falls below 0.8 bar.

- Condensate pressure switch: this intervenes when the flue pressure in the condensate collection tank exceeds 5 mbar.

- Flue safety sensor: this intervenes when the flue temperature is too high.

- Gas pressure switch: this intervenes if the supply gas pressure falls below 14 mbar.

- Hydraulic circuit diagnostics to protect the heating unit against:

- temperature overload, by checking the difference in temperatures on supply and return (ΔT);

- inadequate water circulation in the heat exchanger, checking the difference in temperatures between the heat

exchanger sensor and supply sensor.

b

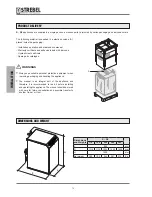

WARNING

•

If a safety devices trips, this means that there is a potentially hazardous appliance malfunction. In this case contact

Technical Services as soon as possible for assistance.

DEVICES

- 5

-

GENERAL

- 5

-