D300XT

D300XT Operator’s Manual

18

When you use a drill bit, drill holes with diameters of 18–25 mm (0.71–0.98

″) in

two steps. First, use the drill bit with the 70% diameter of the required diameter to drill

a hole. Then, keep the machine in the same position, and drill again with the drill bit

that matches the required diameter.

If you are going to drill holes deeper than 50

mm (2″), retract the tool above the

workpiece as often as possible. This allows chips to be removed from the hole. If the

grooves of the tool are clogged, turn off the motor and use a brush to clean them.

After you get to the depth of 40 mm (1.6

″), retract the tool above the workpiece

as often as possible. Then, manually apply the coolant from the bottle into the

drilling area.

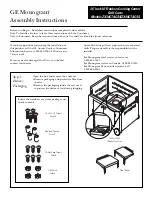

The table that follows shows the meaning of the LED colors.

Color

Meaning

Description

Green is on

Strong surface.

Ready to work.

Green flashes

Weak surface.

We do not recommend work.

White is on

Normal work.

–

Blue flashes

Near overload.

Do not increase the feed speed. This can cause

emergency stop.

Red is on

Overheat.

Immediately retract the tool from the workpiece!

Operate with no load for 2–4 minutes to let the

temperature of the motor decrease.

Blue is on

Emergency stop.

Overload.

Make sure that the tool is sharp. Make sure that

the motor speed and the feed are correct. Use

coolant. Retract the tool from the workpiece,

press STOP, and then start again.

Violet is on

Emergency stop.

Machine tilt/vibrations

or the surface not

stable.

Make sure that the surface is stable and its

thickness is at least 8 mm (0.3

″).

Press STOP

and then start again. If the motor does not

operate, contact the service center.

Red changes to

blue

Emergency stop.

Voltage drop.

Make sure that the power source is correct.

Press STOP and then start again.

Red changes to

green

Emergency stop.

Worn brushes.

Replace the brushes. Let the motor operate

with no load for 20 minutes. If the motor does

not operate, contact the service center.

The green color is indicative only. It does not make sure that the ma-

chine will always be in contact with the surface. Thus, in each posi-

tion protect the machine with the safety strap.

If an overload occurs, the machine stops. The overload can be caused by not

enough cooling, dull tool, too fast feed, or too slow speed. Then, to start the machine

again, retract the tool from the workpiece, press STOP and then

.