6

Standard Pump Operating Instructions and Parts Manual (OIPMS0611)

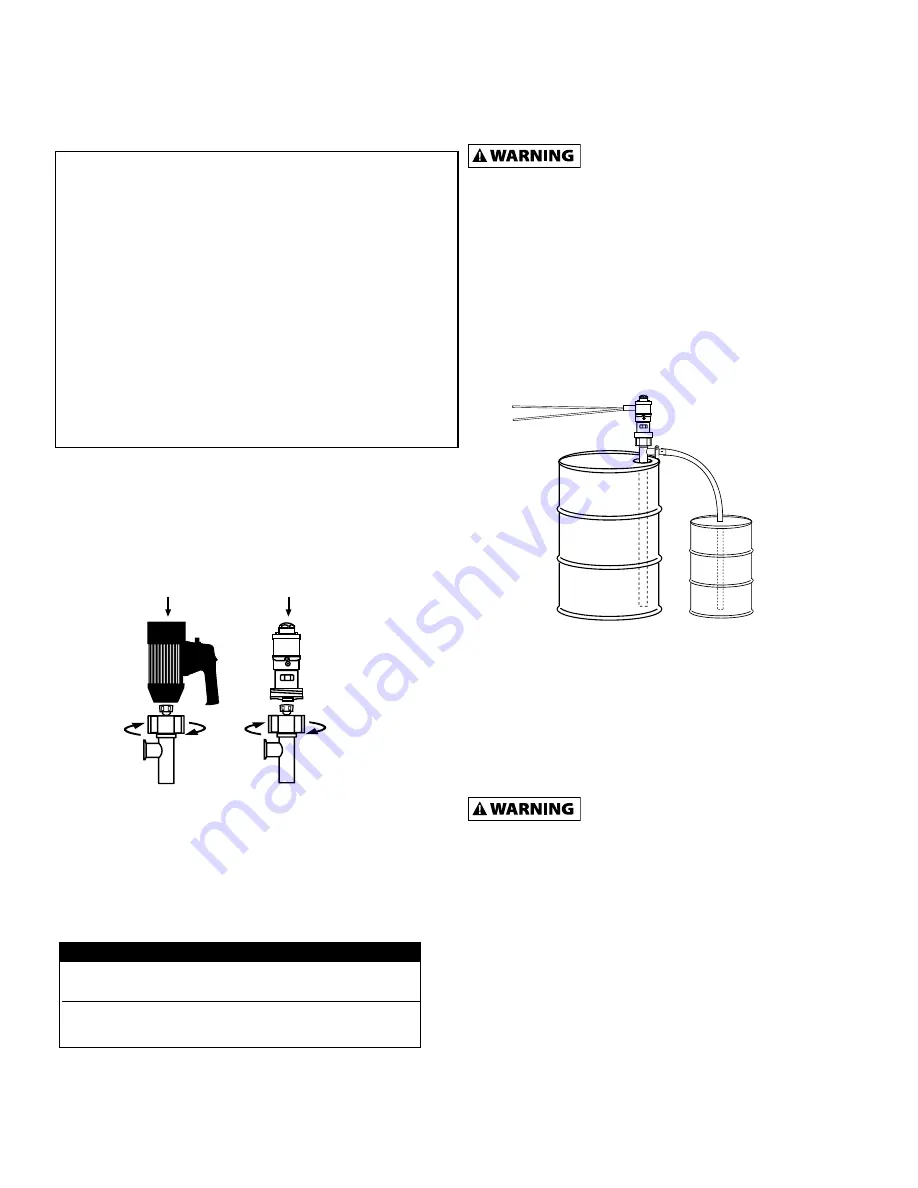

Assembly

1

. Remove the pump and motor from packaging.

2 . Inspect all contents for damage .

3. Couple the motor to the pump tube by using the Hex Nut

(see Figure 1) .

4. First pump clean water in order to familiarize yourself with

the pump’s operation, flow rate, discharge pressure and

motor speed .

5. It is recommended to thoroughly clean and sanitize models

SP-8800 & SP-8900 before operation.

Do not use these pumps for the transfer of

flammable or combustible products or in an

environment where flammable or combustible fumes are present

unless used in conjunction with an Explosion Proof Motor or

SP-A1FP / SP-A2 Series air motor. Please contact the factory or

authorized distributor with any questions regarding this matter

(see page 24).

General Operation Guide (SP-8800 & SP-8900)

1

. Use closed top drum or other cover to avoid possible

contamination .

2. Once the pump is fully cleaned, assembled and all

connections are securely fastened, insert the pump into the

drum or tank .

3. It is recommended to attach a suitable hose or pipe to the

pump discharge.

4. If you opt to use a hose, fasten the hose to the hose

barb with a suitable hose clamp that exceeds the pump

discharge pressure.

Make sure the hose meets the pump

discharge pressure requirements (SP-8800

= 16 psi (1,1 bar)) / (SP-8900 = 32 psi (2,2 bar). It is

recommended to use a hose that is rated 4 x the pump

discharge pressure. Ex: 32 x 4 = 128 psi (9 bar).

5. Turn the motor to the “ON” position.

6. After use, clean the pump and store vertically.

Disassembly / Cleaning Procedures

(SP-8800 & SP-8900)

1. In order to clean a majority of the residue from the pump

tube, immerse the pump into a 55 Gallon Drum of water

or a non-flammable, food safe cleaning agent. Allow the

pump to circulate the water for 3 minutes.

2. For a more thorough cleaning remove the motor from the

pump tube by loosening the connection nut (P/N: 8842)

(see Figure 2) .

SP-8800 & SP-8900 SERIES

Note:

Flow rates are based on water. As viscosity increases, the flow

rate will decrease .

Specifications

Models SP-8800 & SP-8900

Maximum Liquid

Temperature . . . . . . . . . . . . . . . . . . . .175º

F (79

º C)

Pump Type . . . . . . . . . . . . . . . . . . . . . . .Centrifugal

Pump Speed . . . . . . . . . . . . . . . . . . . . .10,000 RPM

Max. Flow Rate

SP-8800

. . . . . . . . . . . . . . . . . . 32 GPM (121 LPM)

SP-8900

. . . . . . . . . . . . . . . . . . . . 15 GPM (57 LPM)

Max. Discharge Pressure SP-8800

. . . . . . . . . . . . . . . . . . . . . . . . 16 psi (1,1 bar)

SP-8900

. . . . . . . . . . . . . . . . . . . . . . . . 32 psi (2,2 bar)

Wetted Materials . . . . . . . . . . . .SS 316, Buna & Teflon

Immersion Length

. . . . . . . . . . .47" (1200 mm) (Tanks)

39

" (1000 mm) (Drums & Barrels)

Discharge Port

. . . . . . . . . . . . . . . . . . . .1 .0"

(25mm) Hose Barb &

1 .5" (38 mm) Tri-Clamp

Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SP-280P Series, SP-ENC Series,

SP-A1FP, SP-A2 Series

Electric

Air

Figure 1

Model

Air Connection

Consumption

SP-A1FP

.125" (3,2 mm)

28 CFM @ 90 psi

13 .2 L/sec @ 6,2 bar

SP-A2L

.25" (6,3 mm)

28 CFM @ 90 psi

SP-A2

13 .2 L/sec @ 6,2 bar

Note:

For optimum performance make sure proper size air

lines are installed .

Air Line

Air Exhaust

Note:

Recommend plumbing discharge air away from drum or

tank to prevent possible contamination . Left port is air intake,

right port is air exhaust.