Lit. No. 78565, Rev. 02

20

November 1, 2019

MAINTENANCE

LUBRICATION

To keep your spreader running smoothly, observe the

following recommendations:

• Lubricate bearings after every 20 hours of use.

• Apply a small amount of light oil to latches as

needed.

AFTER EACH USE

•

Wash out the hopper and rinse off all external

surfaces.

• Apply dielectric grease on all electrical

connections to prevent corrosion.

AT THE END OF EACH SEASON

OR AFTER EXTENDED STORAGE

•

Wash out the hopper and rinse off all external

surfaces.

• Apply dielectric grease on all electrical

connections to prevent corrosion.

•

Lubricate all grease fittings with good quality

multipurpose grease.

• Oil or paint all bare metal surfaces.

• If motor cover is removed for any reason, use

silicone sealant to ensure weather proofing of

enclosure.

STORAGE

Unplug the cab control from the control harness at the

end of the season, or when the spreader is removed

from the vehicle. Store the spreader and cab control in

a clean, dry location, away from direct sunlight.

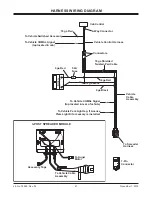

FUSE REPLACEMENT

See the Harness Wiring Diagram on the following

page for fuse ratings and locations.

If a problem should occur and fuse replacement is

necessary, the replacement fuse must be of the same

type and amperage rating as the original. Installing a

fuse with a higher rating can damage the system and

could start a fire.

WARNING

Never remove the spreader with material in

the hopper.

CAUTION

• When replacing parts use only original

manufacturer's parts. Failure to do so will

void warranty.

• The control is a solid-state electronic unit

and is not serviceable. Any attempt to

service will void warranty.

• There are no serviceable parts in the

motor/transmission assembly. Any attempt

to service will void warranty.

• When pressure washing motor enclosure

area, keep spray at least 36" away from

motor enclosures.

CAUTION

Disconnect electric power at spreader

electrical wiring harness connection and tag

out if required before servicing or performing

maintenance.

CAUTION

DO NOT leave unused material in

hopper. Material can freeze or solidify,

causing unit to not work properly.

Empty and clean after each use.

Содержание Drop Pro 600

Страница 2: ......

Страница 4: ...Lit No 78565 Rev 02 4 November 1 2019...