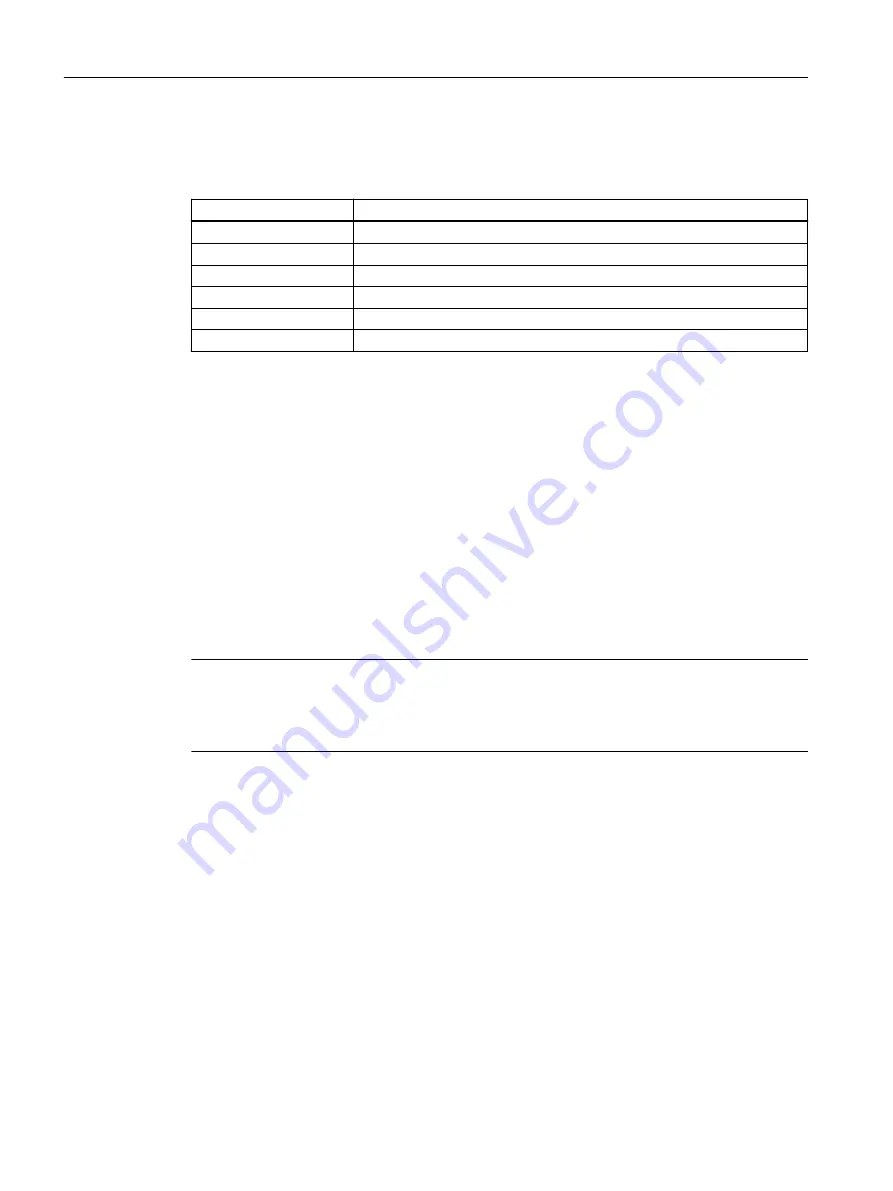

The following measured values are available in the order specified:

Table B-1

Cyclic data transmission, measured values

Slot No.

Parameter / measured value

1

Flow (volume or mass flow)

2

Sound velocity

3

Quantity (volume or mass) net

4

Ultrasonic amplitude

5

Quantity (volume or mass) forward

6

Quantity (volume or mass) reverse

Output data are sent to the device together with the cyclic request telegram. The number and

type of actually transferred data can be determined with the aid of the configuration data (see

GSD files (Page 98)).

B.2

Acyclic Data Transmission

The acyclic data transmission is mainly used for remote control of devices, i.e. for transmitting

parameters during commissioning, maintenance, batch processes or for displaying variables

which are not included in the cyclic process data traffic.

Acyclic accesses can be carried out by Master class 1 (C1 connection) or Master class 2 (C2

connection). SITRANS FUS060 PROFIBUS PA supports up to 4 simultaneous C2 connections.

The approximately 400 parameters including address (slot and index), format, value range, start

value and attributes are stored in an object list "Obj8159.rtf" which will be provided on request.

Note

Acyclic operation with SIMATIC PDM

We recommend using the SIMATIC PDM software package and a PC (compatible with industry

standard) or a programming unit for acyclic operation.

B.3

Input Data (from Slave to Master)

Input data are process data (measured values) which are transmitted from the device to the

master in the following format:

Every measured value consists of 5 bytes which are composed of a floating point value

corresponding with IEEE - 754 (4 bytes) and the correspondent measured value status (1 byte).

PROFIBUS communication

B.3 Input Data (from Slave to Master)

SITRANS FUS060 with PROFIBUS PA

90

Operating Instructions, 09/2021, A5E02225054-AD