10

SE 80/185 T - SE 100/185 T - SE 130/250T

1.0.1- 2008

Tunnel installering

Tunnel installation

N

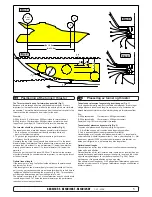

Rund av tunnelendene med en radius 10% av tunneldiameter (Fig. 1a),

eller lag en skråkant 10-15% av tunneldiameter (Fig. 1c). Der dette ikke er

mulig skal tunnel kantene rundes av mest mulig.

Vi anbefaler å støpe to lag utenpå tunnellavrundingen og over et område

på 6-8cm (Fig. 1c & 1d).

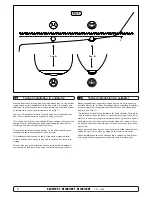

Gelcoat eller lignende må påføres på områdene der det har blitt pusset

eller støpt for å gjøre glassfiberen vanntett.

NB ! Alle originale Sidepower tunneler er vanntette ved levering!

Så fremt man ikke ønsker en annen farge er det ikke nødvendig å påføre

Gelkoat, Topkoat og flere lag med primer for å gjøre tunnelen vanntett.

Puss tunnelen med fint slipepapir og påfør et lag primer for å få bunnstoff

til å sitte.

Sidepowertunnelen er helt vanntett uten behandling med unntak av de

områder det som er støpt fast i skroget.

Påfør Gelcoat/Topcoat/epoxy og primer på de områder som er pusset ned

eller støpt. Vann skal ikke ha direkte kontakt med glassfiberen i skroget

fordi dette normalt ikke er vanntett.

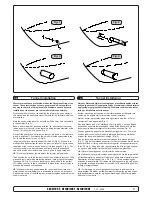

PS ! Det må ikke støpes der brakketen til thrusteren skal stå. Pass-

formen er nøyaktig tilpasset, og en feilplassert braket kan forår-

sake svikt i girhus.

GB

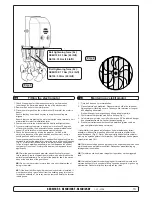

Fig. 1a

Fig. 3

Fig. 2

Fig. 1b

Fig. 1c

Fig. 1d

Fig. 1

Soften the edges with a radius of 10% of the tunnel diameter (Fig. 1a) or

make a slope with a length of 10-15% of the tunnel diameter (Fig. 1c). If

this is not possible, at least round the tunnel end as much as possible.

We advice to also cast two layers on the outside of the tunnel/hull for an

6-8cm area (Fig. 1c & 1d).

You must apply topcoat/epoxy on the areas outside where you have

grounded or moulded to again make these waterproof.

NB! All original Sidepower tunnels are fully waterproof when

they are delivered.

This means that unless you want, because of special reasons, to have an-

other colour on it, you do not have to apply topcoat or the several layers

of primer that is necessary on the boats’ hull to make it water-resistant.

Sand it very lightly and apply one layer of primer to make the antifouling

sit.

The original Sidepower tube itself is fully water-resistant without treatment

except in the areas where you have bonded it to the hull.

Apply topcoat/epoxy paint and primer on the areas where you have

grounded or moulded as these areas give the water access to the hull

which normally is not waterproof without these applications outside.

PS! Avoid all casting where the motor-bracket is to be placed,

as this will cause misfit and possible failure of the

gearhouse.