E

n

g

lis

h

E

n

g

lis

h

6

7

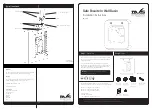

Securing instructions

Anchoring option is for Secure Doc Executive only

(not applicable for Secure Disc)

Recommendation

We recommend that you:

• Position the safe as near to the floor as

possible in case of outbreak of fire.

• Secure your safe with the anchoring bolt

provided to the floor. This offers the best

protection against unauthorised removal of

your safe.

Your safe is equipped with one hole in the bottom.

Using the fixing set supplied, you can secure the

safe to the floor. For details, see figure 1.

If you wish to install it on a wooden floor it may be

desirable to use different fixings to ensure optimum

fixing strength. Various types of anchor bolts are

available for use in wood which can give a better

result that the screws supplied. The choice of

fixings is largely determined by the thickness and

type of wood on which the safe is placed.

What do you need?

To secure the safe you need fixings and tools.

Before starting to secure the safe, check that you

have the following items to hand:

1. The fixing set supplied.

2. An electric (hammer) drill. If the base material

is concrete, you will need a hammer drill.

3. The fixing hole in the base material needs to

be drilled first. If the base material is concrete

or stone, you will need a concrete drill bit. If the

base material is wood, use wood drill bit. Note:

you may therefore require both drill bits, for

example if the floor is made of concrete and

the wall is wood.

4. A socket wrench.

5. A vacuum cleaner to clear the drill holes.

6. Possibly a hammer.

Installation instructions

1. Place the safe in the position you have

selected. Before marking or drilling any holes

ensure that there are no pipes or cables

present at the fixing points. If there is skirting

board present at the desired fixing point, this

should be removed to allow the safe to be

fitted flush to the wall.

2. Open the safe and remove any shelves and /

or trays.

3. Remove the metal cover with a screwdriver to

gain access to the anchoring hole.

4. Using a pencil or a sharp object, mark out the

drill hole.

5. Close the safe.

6. Now move the safe to give enough room to

drill the fixing hole.

7. Drill the hole: you will need the concrete drill bit

for a concrete base material, and the wood drill

bit for a wooden base material.

8. Clear the drill hole and remove any drilling

debris using a vacuum cleaner.

9. If you have drilled hole in a concrete floor,

ensure that the end of the plug is level with the

edge of the drill hole. If necessary, use a

hammer to insert the plug. The plugs are not

used when securing the safe to a wooden

floor.

10.Now position the safe so that the fixing holes

on safe match the drill holes in the floor.

11.Secure the safe using the fixing screws

supplied. Slide the washer over the fixing

screw before screwing it into the drill hole. You

will need a socket wrench to drive in the screw.

12.You can cover the hole again with the metal

cover.

Maintenance

• Never throw your keys. Distortion of the key

can damage the lock.

• When closing the door, there should never be

anything between the door and the safe (e.g. a

paper clip). The bolts must be fully retracted.

• Do not fill the safe to such an extent that it is

hard to close the door. The locking mechanism

could then seize up as a result of pressure on

the inner plate.

• Ensure that the key in the door does not hit a

wall when opening. This can cause the key to

snap, and can damage the locking

mechanism.

• If you find that the lock becomes harder to

open or stiffer, never use oil or graphite

powder to “lubricate” the lock. This can make

the tumblers sticky, which could prevent the

lock from opening at all. Your supplier can

advise you on the correct cleaning product to

use.

• The outside of your safe can be cleaned with a

slightly damp cloth. Never use chemical

cleaning agents.

Troubleshooting

Although your safe has been manufactured with

the greatest care, a fault may nevertheless occur,

such as:

• The locking mechanism does not work

• You cannot open your safe

• Faulty lock

• You lose your key

The most important rule is not to try and force

anything. The locking mechanism in particular

is made of precision components which can be

damaged.

First re-read the manual. If you cannot find a

solution, contact your supplier.

Figure 1