Section 04 ENGINE MANAGEMENT (1503 4-TEC)

Subsection 01 (OVERVIEW)

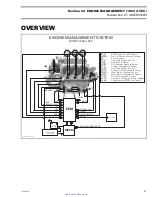

ENGINE MANAGEMENT

SYSTEM (EMS)

A highly advanced EMS has been used to ensure

a high power output with cleanest combustion.

The EMS calculates the proper air/fuel mixture and

ignition timing for each cylinder separately.

NOTE:

The EMS includes an ECM (engine control

module), MPEM (multi-purpose electronic mod-

ule), sensors, injectors, electromagnetic valves

and ignition components.

The EMS is controlled by its ECM (Engine Control

Module).

ECM (Engine Control Module)

1

R1503motr215A

TYPICAL

1. ECM

The ECM is mounted on the intake manifold. It

controls all engine management functions, by pro-

cessing the information given by various sensors.

1

R1503motr214A

TYPICAL

1. ECM on intake manifold

The ECM gets its power by the MPEM which is di-

rectly powered by the battery. It is responsible for

the following engine management/electrical func-

tions:

– interpreting information

– distributing information

– start/stop function

– DESS (Digitally Encoded Security System)

– ignition timing control

– injection control

– engine RPM limiter

– etc.

The ECM applies the proper map (injection and ig-

nition) for optimum engine operation in all condi-

tions.

The ECM also stores the fault codes and gener-

al information such as: operating conditions, ve-

hicle hours, serial numbers, customer and main-

tenance information. The ECM features a perma-

nent memory that will keep these informations,

even when the battery is removed from the wa-

tercraft.

Multi-Purpose Electronic Module

(MPEM)

The MPEM distributes power from battery to all

accessories and the ECM. Accessories are pro-

tected by fuses integrated in the MPEM. Fuse rat-

ings is identified besides their holder.

72

smr2005-011

www.SeaDooManuals.net