Operation & Maintenance Manual

──

LG968 /969Wheel Loader

92

z

Always

fill the fuel tank after finishing operation to prevent the moisture in the air from

condensing and forming water inside the fuel tank.

z

If engine fails to suck fuel or the filters have been replaced just, bleed the air in the circuit.

2.1.2 Coolant

z

Use the clean and soft water, rain or tap water as coolant. Well water and spring water can be

used as coolant after soft processing and precipitation to avoid bringing scale which can influence

the performance of heat exchange.

z

If the engine overheats, wait for the engine to cool before adding coolant.

z

Add coolant to specified level. If the level is too low, it will cause overheating of engine system

and corrosion of cooling system.

z

Add antifreeze to coolant if ambient temperature is lower than 0

℃

. Drain the coolant out after

working (please see “

CHAPTER III 3.5.3 Operation in Cold Weather

”) and refill

before next working if there is no antifreeze in the coolant.

z

Antifreeze is flammable. Keep fire off when the antifreeze is added.

z

Never

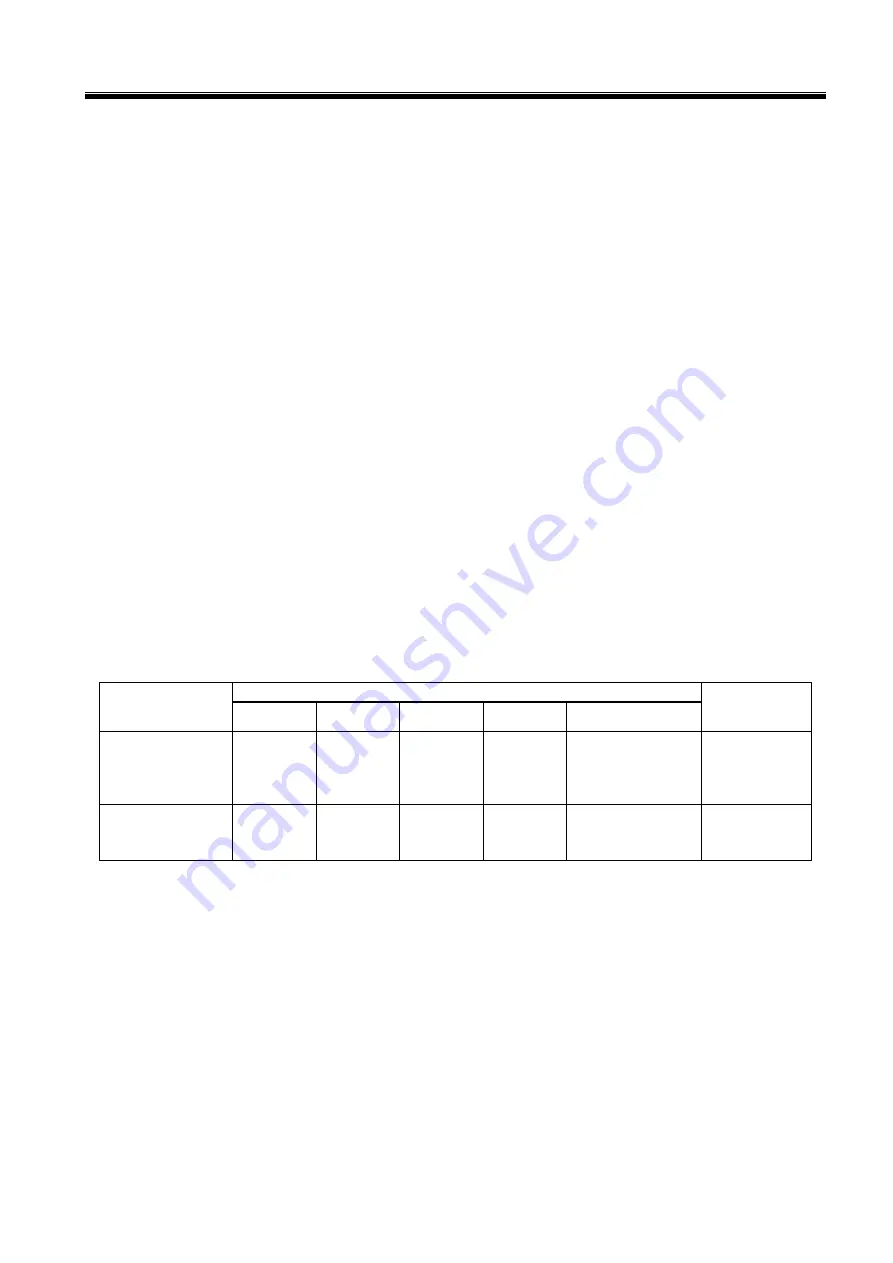

use 100% antifreeze as coolant. Refer to the following table to select the mixing

proportion.

Proportion%

Name

Glycol Alcohol Glycerin Water

Proportion

Freezing

point

≤

℃

Glycol

60

55

50

40

40

45

50

60

Proportion in

volume

-55

-40

-32

-22

Alcohol

Glycerin

Antifreeze

30

40

42

10

15

15

60

45

43

Proportion in

weight

-18

-26

-32

2.1.3 Grease

z

Grease is used to prevent wear and noise on the joint surfaces.

z

Joints not included in the manual (connectors, jointing sleeves) are treated during overhaul, so

they do not need grease. When some parts become inflexible because of long-time operation, it is

necessary to grease them.

z

Remember to wipe off the overflow grease when adding grease.

2.1.4 The Storage of Oil and Fuel

z

Prevent water, dirt or other impurities from getting in.

z

Follow the rule that the oldest oil or fuel is used first to prevent any change in quality during