•

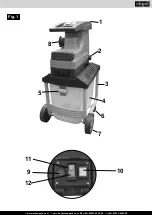

Turn the adjustment wheel (Fig.1, No.2) clockwise until you can

hear slight grinding sounds.

•

When turning the adjustment wheel (Fig.1, No.2) clockwise by half

a turn, the blade cylinder is positioned closer to the counter blade

by 0.50 mm.

WARNING: If the shredder blade touches the counter blade, it will

be trimmed and small pieces of swarf may fall out of the ejection

opening. This is not an error, but it has to be re-adjusted to the

required degree because otherwise the counter blade will wear too

early.

Overload protection

In the event of overload, e.g. due to branches that are too thick, the

equipment automatically switches off.

After a short cooling period (approximately 5 minutes), press the reset

switch (pos 6)

Electric connection

The installed electric motor is connected and operational. The connec-

tion complies with relevant VDE and DIN stipulations.

The customer’s mains connection as well as the extension lead used

must comply with these provisions.

Hazardous electric connections

Insulation damage often occurs on electric connections.

Causes include:

• Pressure marks when connections are guided through windows and

doors

• Kinks due to inappropriate attachment or guidance of the connection

• Cuts when the connection is run over

• Insulation damage when being pulled out of the wall socket

• Tears from ageing insulation

Such hazardous electric connections must not be used and are

dange-

rous to life

due to the insulation damage.

Regularly check electric connections for damage. Make sure the

connection is not connected to the mains when checking. Electric

connections must comply with relevant VDE and DIN stipulations. Only

use connections marked H 07 RN. Printing the type designation on the

connection is the law.

AC motor

• The power voltage has to be 230 Volt – 50 Hz.

• Extension leads up to 25 m in length must have a cross section of

1.5 mm

2

, and at more than 25 m length, it has to be at least 2.5 mm

2

.

• The mains connection is protected against short circuit with a 16 A

slow fuse.

Connections and repairs to the electrical equipment may only be

carried out by a trained electrician.

If there are any questions, please provide the following data:

• Motor’s type of power

• Data from the machine’s type plate

When sending back the motor, always send the entire motor unit with

switch.

Follow the safety notices!

Cleaning, maintenance and repair

• Cleaning, maintenance and repair work may only be carried out

when the motor has been turned off and the machine has been

disconnected from the mains.

• Work on the electrical equipment, may only be carried out by

trained electricians.

• Wear gloves when handling the cylinder blade.

• Do not spray the shredder with water. Risk of electric shock.

• Always keep the machine, the wheels and the ventilation opening

clean. When cleaning, use a brush or a cloth, but not detergents or

solvents.

• Before every use, check the machine, and particularly safety devices,

for damage such as loose, worn or damaged parts. Check that all

nuts, bolts and screws are tight.

• Check covers and safety devices for damage and correct positioning.

Replace if required.

• Store the machine in a dry location and beyond the reach of children.

Troubleshooting

Problem

Possible cause

Solution

Motor does not start.

Collection box not in correct position

Insert the collection box correctly and check

the locking device (see Commissioning).

Motor is overloaded.

Turn the shredder on again (see Commissio-

ning).

No electricity

Have the socket, cable, lead and plug che-

cked by a trained electrician (see Electric

connection).

Garden waste is not drawn in.

Blade cylinder rotates anti-clockwise.

Change the rotational direction (see Commis-

sioning).

Shredding material is too soft.

Push shredding material with special pushing

device for shredder.

Blade cylinder has become blocked.

Remove blockage (see Commissioning).

Shredding material is tangled.

Counter blade is not set correctly.

Re-adjust counter blade (see Commissioning).

Bei Fehlern, die Sie nicht selbst beheben können, wenden Sie sich bitte an den Service der Firma scheppach.

E-Mail: [email protected]

Telefon: 00 49/82 23/ 40 02-99

GB

15