SAMES KREMLIN

Page 2

Manual : 573.186.112

Dear Customer,

You are the owner of our new color changer and we would like to take this opportunity to thank

you.

To make sure your investment will provide full satisfaction, special care has been taken by

SAMES KREMLIN during all designing and manufacturing processes.

To obtain the best result, safe and efficient operation of your equipment, we advice you to read and

make yourself familiar with this instruction and service manual. Indeed, the non-compliance with

instructions and precautions stated in this manual could reduce the equipment working-life, result in

operating trouble and create unsafe conditions.

1. GENERAL SAFETY INSTRUCTIONS

The personnel involved in operating and servicing this equipment must be aware of all safety

requirements stated in this manual. The workshop supervisor must be certain that the personnel

has perfectly understood the safety instructions and complies with them.

Use the equipments only in a well-ventilated area to prevent from serious body injuries, fire and

explosion hazards.

Spraying of some materials may result in hazardous working conditions. To protect the operator,

respirator mask, hand cream and glasses are required.

The operating pressure of these equipments are particularly high. Consequently, some precau-

tions must be taken in order to prevent from accidents and from unsafe working conditions.

2. DESCRIPTION

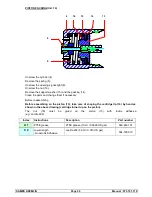

The color changer is composed of several stackings modules.

It enables a quick color change without material handling. As a result, costs through down time and

solvent consumption are dramatically reduced.

Thre is no dead volume thus allowing a full flushing.

It is used on automatic installations and also on optimized manual installation. A color changer

consists of :

1 end module (inlet),

x intermediate modules,

1

outlet

flange,

2

tie-rods.

The end module and the intermediate modules are fitted with two air operated valves. Each valve

feeds the central fluid passage with the selected color.

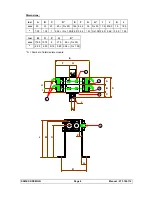

Select the appropriate modules and valves according to the application :

airspray

(low

pressure),

AIRMIX (medium pressure - 120 bar / 1740 psi),

AIRMIX (high pressure - 200 bar / 2900 psi).

With the required color valves, add a solvent valve for the flushing and, if necessary, an additional

valve to provide compressed air to speed up the flushing process.

On a color changer, the number of valves is

always

an even number.