Malfunction and Remedies

Hydraulic valves

519 / 564

2

5

Once the repair work is completed, the spring-loaded actuator must be activated as

follows:

– Unscrew again the emergency release nut with the ring wrench (

5

) counterclock-

wise with noticeable resistance.

– The housing must be closed using the screw-on cover again.

– After completing all work, perform a brake test.

ADVICE

The basic setting of the brake is not affected by the emergency release process!

8.12

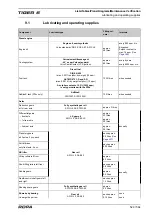

Hydraulic valves

All hydraulic valves are electrically controlled. Problems with solenoid valves may be

detected using specific test cables, which are supplied with each machine. These test

cables may only be connected to the solenoid valves by trained and instructed spe-

cialist personnel.

Should an electrically controlled valve malfunction, then in any case, without excep-

tion, call in a specialist. Never try to shake the solenoid valve concerned to remedy

possible contact problems or a possible line break. If the valve is suddenly opened

during such tries, then the person concerned may suffer deadly injuries.

WARNING

Searching and remedying malfunctions on all components of the hydraulic system is

exclusively the task of trained specialists. We expressly warn of tries to repair or self-

performed tests on hydraulic valves under electro-magnetic control. If during such

tests or tries to repair, parts of the hydraulic system are suddenly put under pressure,

then this may trigger unwanted machine movement. This may pinch or even crush

people or body parts.

Содержание Tiger 6

Страница 3: ...Contents 3 564 Contents...

Страница 4: ...Contents 4 564...

Страница 13: ...Preface 13 564 1 Preface...

Страница 14: ...Preface 14 564...

Страница 22: ...Safety 22 564...

Страница 23: ...Safety 23 564 2 Safety...

Страница 24: ...Safety 24 564...

Страница 41: ...General View and Specifications 41 564 3 General View and Specifications...

Страница 42: ...General View and Specifications 42 564...

Страница 53: ...General Description 53 564 4 General Description...

Страница 54: ...General Description 54 564...

Страница 57: ...Operating Components 57 564 5 Operating Components...

Страница 58: ...Operating Components 58 564...

Страница 63: ...Operating Components Driver s cabin overview 63 564 13 14 15 13 First aid box 14 Blow gun 15 USB interface...

Страница 98: ...Operation 98 564...

Страница 99: ...Operation 99 564 6 Operation...

Страница 100: ...Operation 100 564...

Страница 226: ...Operation Defoliator 226 564 RIS defoliator RES defoliator...

Страница 256: ...Operation Lifter 256 564 6 14 4 Setting rollers movement height High rollers movement High rollers movement...

Страница 291: ...Operation Infeed conveyor 291 564 2 1 1 Infeed conveyor control block...

Страница 299: ...Operation Strainer wheels turbines 299 564 4 Rpm strainer wheels...

Страница 325: ...Operation Bunker unloading 325 564 6 19 Bunker unloading...

Страница 327: ...Operation Bunker unloading 327 564 45 51 50 47 46 52 53 54 48 55 49 56 Key overview See Page 88...

Страница 361: ...Maintenance and Service 361 564 7 Maintenance and Service...

Страница 362: ...Maintenance and Service 362 564...

Страница 418: ...Maintenance and Service Defoliator 418 564 Defoliator in the maintenance position...

Страница 475: ...Malfunction and Remedies 475 564 8 Malfunction and Remedies...

Страница 476: ...Malfunction and Remedies 476 564...

Страница 527: ...Lists Tables Plans Diagrams Maintenance Verification 527 564 9 Lists Tables Plans Diagrams Maintenance Verification...

Страница 528: ...Lists Tables Plans Diagrams Maintenance Verification 528 564...

Страница 558: ...558 564...

Страница 559: ...Index 559 564 10 Index...

Страница 560: ...Index 560 564...