RS-Helios-1610 User Manual

7

black zinc, grade 10.9, with drop resistance coating.

GB/T70.1, M3x8, hexagon socket head, material SCM435, electroplated trivalent chromium black

zinc, grade 10.9, with drop resistance coating.

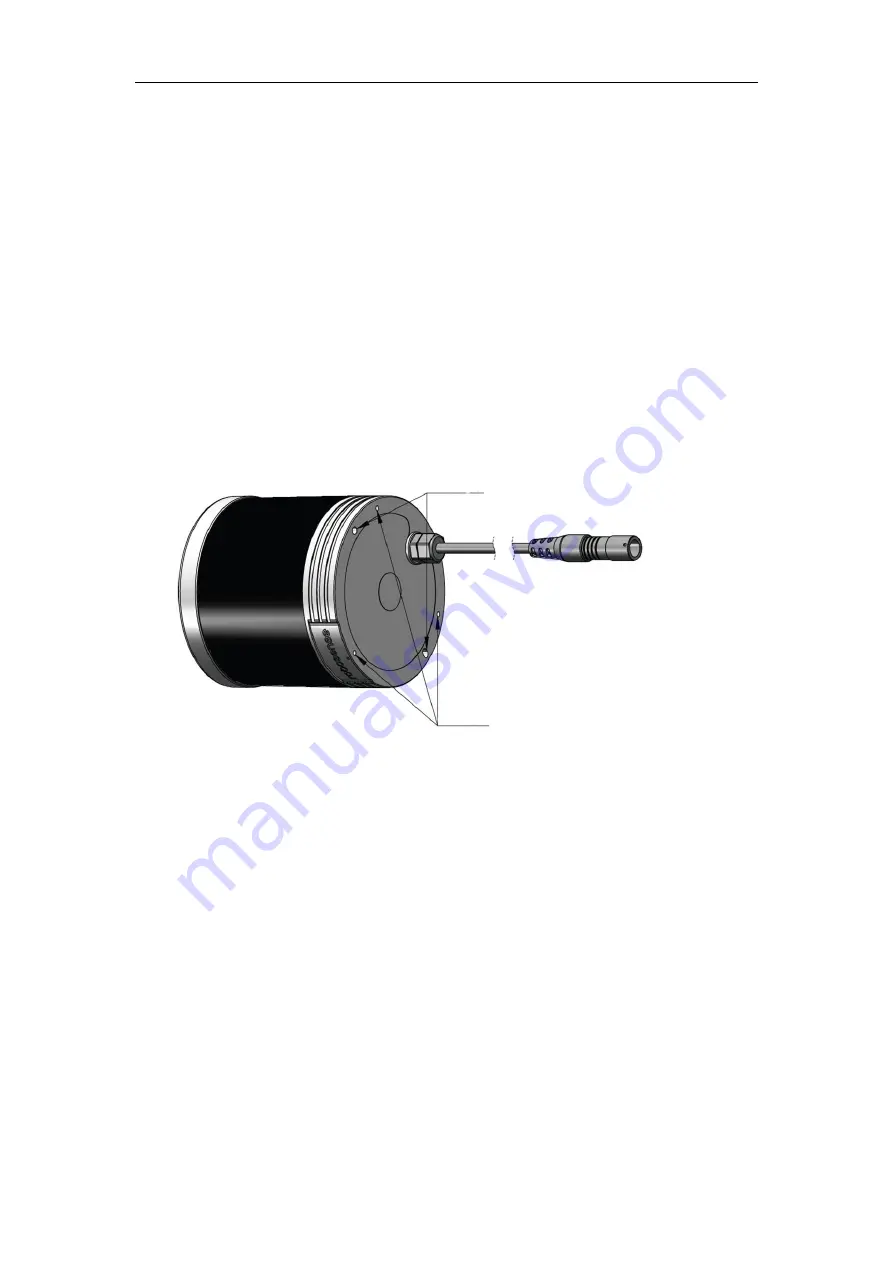

Mounting Requirements

1) The mounting surface should be as flat as possible with the flatness be better than 0.05mm;

2) Use 3xM3 mounting screws to fix the LiDAR on the mounting surface, the screw should be

4~5mm above the mounting surface, the recommended tightening torque is 13±1kgf.cm;

3) Use 2xΦ4 locating pins to locate the LiDAR on the mounting surface, the pin should be

4~5mm above the mounting surface.

Figure 5 LiDAR Mounting Holes & Locating Holes Diagram

Mounting Bracket Rigidity Requirements

The mounting bracket where the LiDAR is attached to should be rigid enough to ensure LiDAR in a

stable operating state under various working conditions. Therefore, it is required that the

first-order modal frequency of the LiDAR and the mounting bracket should be greater than 50Hz,

and avoiding frequency range of 100~110Hz and 280-290Hz;

The LiDAR will be subjected to various random vibrations, mechanical shocks and other operating

conditions during use. Under these conditions, the bracket needs to be strong enough to bear a

relatively large load.

The following situations should be avoided when mounting the LiDAR:

1) The mounting surface of the LiDAR should be flat and uneven surfaces should be avoided.

2) The precise locator pins on the mounting base should strictly follow the dimensions of the

2 x

Φ

4 Locating holes

3 x M3 Mounting holes

Содержание RS-Helios-1610

Страница 1: ...RS Helios 1610 User Manual RS Helios 1610...

Страница 58: ...RS Helios 1610 User Manual 52 Appendix E Mechanical Drawings...

Страница 60: ...RS Helios 1610 User Manual...