21

6.8 LOWER AUTOMATIC AIR RELEASE VALVE

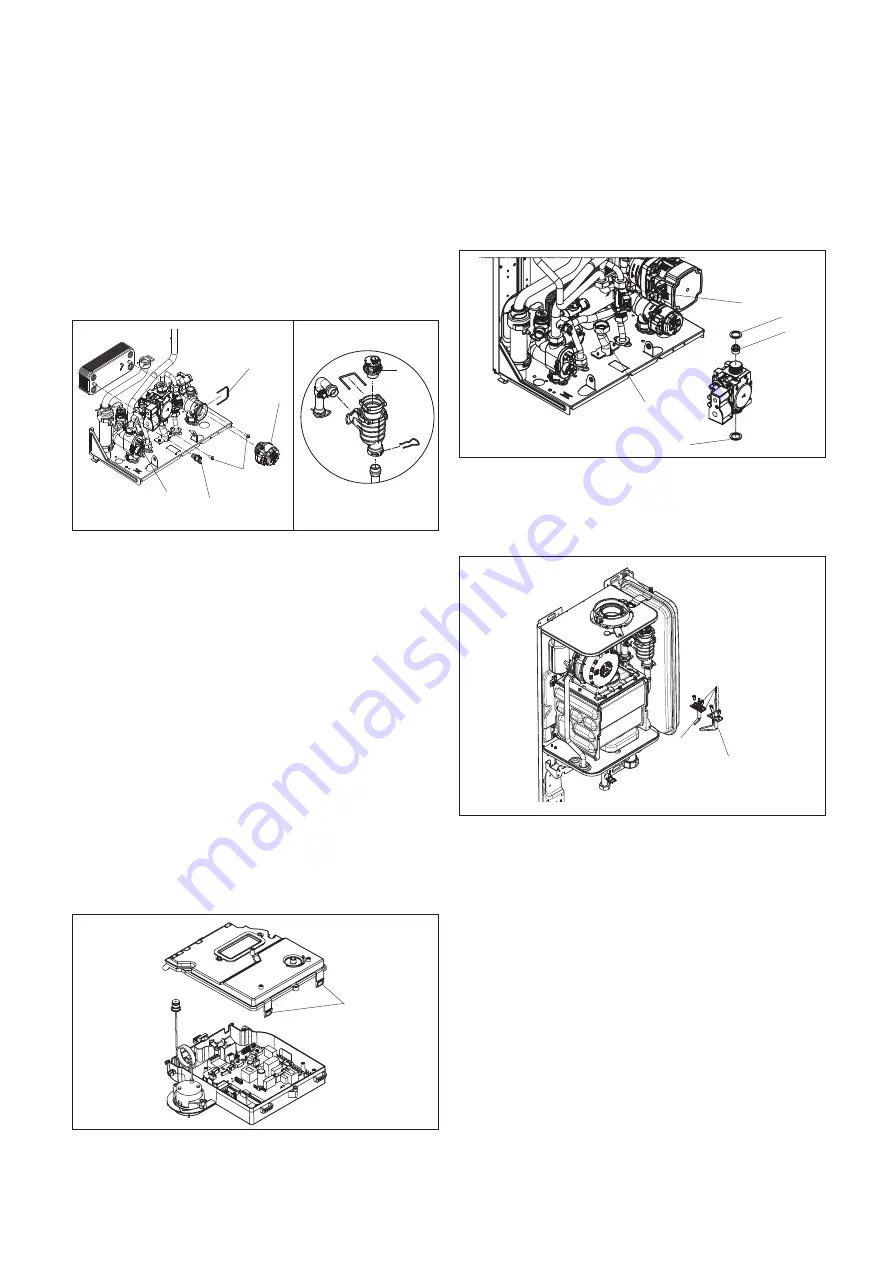

(fig. 29)

Carry out component removal procedure as described in 6.4.

Remove the expansion pipe locking pin (

B

) from the pump as-

sembly and remove the expansion pipe. Locate and remove

the AAV locking pin (

I

) from the pump assembly and remove

the AAV assembly (

J

). Replace in the reverse order.

6.8.1 TOP AUTOMATIC AIR RELEASE VALVE (fig. 31)

Carry out component removal procedure as described in 6.4.

Unclip and remove the air chamber front cover. Remove the

AAV locking pin (

K

) from the deaerator assembly and remove

the AAV assembly (

L

). Replace in the reverse order.

6.9 WATER PRESSURE SWITCH (fig. 30)

Carry out component removal procedure as described in 6.4.

Locate and remove the locking pin (

M

) from the water pressure

switch (

N

). Remove the wiring. Carefully withdraw the switch.

Replace in the reverse order.

Fig. 30

Fig. 31

M

N

Y3

G2

H2

K

L

6.10 FLOW THERMISTOR (fig. 5 - pos. 18)

Carry out component removal procedure as described in 6.4.

Unclip and remove the air chamber front cover. Unclip the flow

thermistor from the flow outlet pipe. Disconnect thermistor

electrical plug. Replace in the reverse order.

6.11 RETURN THERMISTOR (fig. 5 - pos. 20)

Carry out component removal procedure as described in 6.4.

Unclip the return thermistor from the return inlet pipe. Discon-

nect thermistor electrical plug. Replace in the reverse order.

6.12 PRINTED CIRCUIT BOARD (fig. 33)

Carry out component removal procedure as described in 6.4.

Pull the control fascia forward and lower it. Push the clips (

O

)

which secure the PCB cover, remove cover, after carefully tak-

ing note of all wiring connections and jumper tag configuration.

Disconnect all wiring from the PCB, locate and remove the

PCB securing screws, remove the required PCB. Replace in

the reverse order ensuring that the position of the 2 control

knobs are correctly aligned with the respective potentiometers

on the PCB.

Ensure that the correct jumper tag configuration has been

respected. It will be necessary to check the functioning of the

PCB is set for the correct boiler output, type and application.

Details on setting fan speeds can be found in section 7.10.

Fig. 33

O

6.13 GAS VALVE (fig. 34)

Carry out component removal procedure as described in 6.4.

The gas valve must be changed as complete unit. Disconnect

the electrical plug and leads from the gas valve, slacken and

unscrew gas valve inlet

and outlet connections.

Please note,

the sealing washers (

Q

) must be discarded and

replaced with new sealing washers.

Unscrew gas pipe connections (

S-T

), the gas valve can now

be removed. Replace in the reverse order. Check and adjust

burner pressure settings.

WARNING, A GAS TIGHTNESS CHECK MUST BE CAR-

RIED OUT.

6.13.1 INJECTOR (fig. 34)

Carry out component removal procedure as described in 6.4.

Unscrew and remove gas pipe connections (

S-T

). Locate and

remove the injector (

U

) inside the valve. Replace in the reverse

order. Check and adjust burner pressure settings.

WARNING, A GAS TIGHTNESS CHECK MUST BE CAR-

RIED OUT.

Fig. 34

Q

Q

U

S

T

6.14 ELECTRODES (fig. 35)

Carry out component removal procedure as described in 6.4.

Remove the air chamber front cover. Disconnect the electrode

leads and ancillary wiring from their respective connectors. Re-

move the retaining screws (

V

) for electrode. Remove the spark

ignition electrode (

W

). Remove the flame sensor electrod (

Y

).

Fig. 35

V

W

Y

6.15 FLUE FAN+MIXER (fig. 36-37)

Carry out component removal procedure as described in 6.4.

Remove the air chamber front cover. Locate and remove the

gas pipe locking pin (

A1

) and swing/rotate the gas pipe away

from the fan assembly (

B1

), (if necessary unscrew the gas

pipe from the gas valve

G1

). Locate and slacken the silencer

(

H1

). Locate and remove the sense electrode. To remove the

fan (

E1

), disconnect the electrical connections attached to the

fan, locate and remove the four screws (

F1

). Gently ease the

fan from its location. Replace in the reverse order. Ensure all

seals are in good condition, taking care to ensure they are

replaced correctly.

6.16 BURNER (fig. 36)

Carry out component removal procedure as described in 6.4.

Remove the air chamber front cover. Locate and remove the

gas pipe locking pin (

A1

) and swing/rotate the gas pipe away

from the fan assembly (

B1

), (if necessary unscrew the gas

pipe from the gas valve

G1

). Locate and slacken the silencer

(

H1

), disconnect the electrical connections attached to the

fan. Disconnect the electrode leads and ancillary wiring from

their respective connectors. Locate and remove the screws

(

I1

) which secure the burner assembly in position to the heat

exchanger (

J1

). Gently ease the fan assembly out of its location.

Once the assembly has been removed, the burner (

K1

) can

be withdrawn from the heat engine. Ensure the seals (

L1

) is in

good condition, taking care to ensure it is replaced correctly.

Replace in the reverse order.