3 December 2004

LED FUNCTION MODE

4-3

Trouble-

shooting

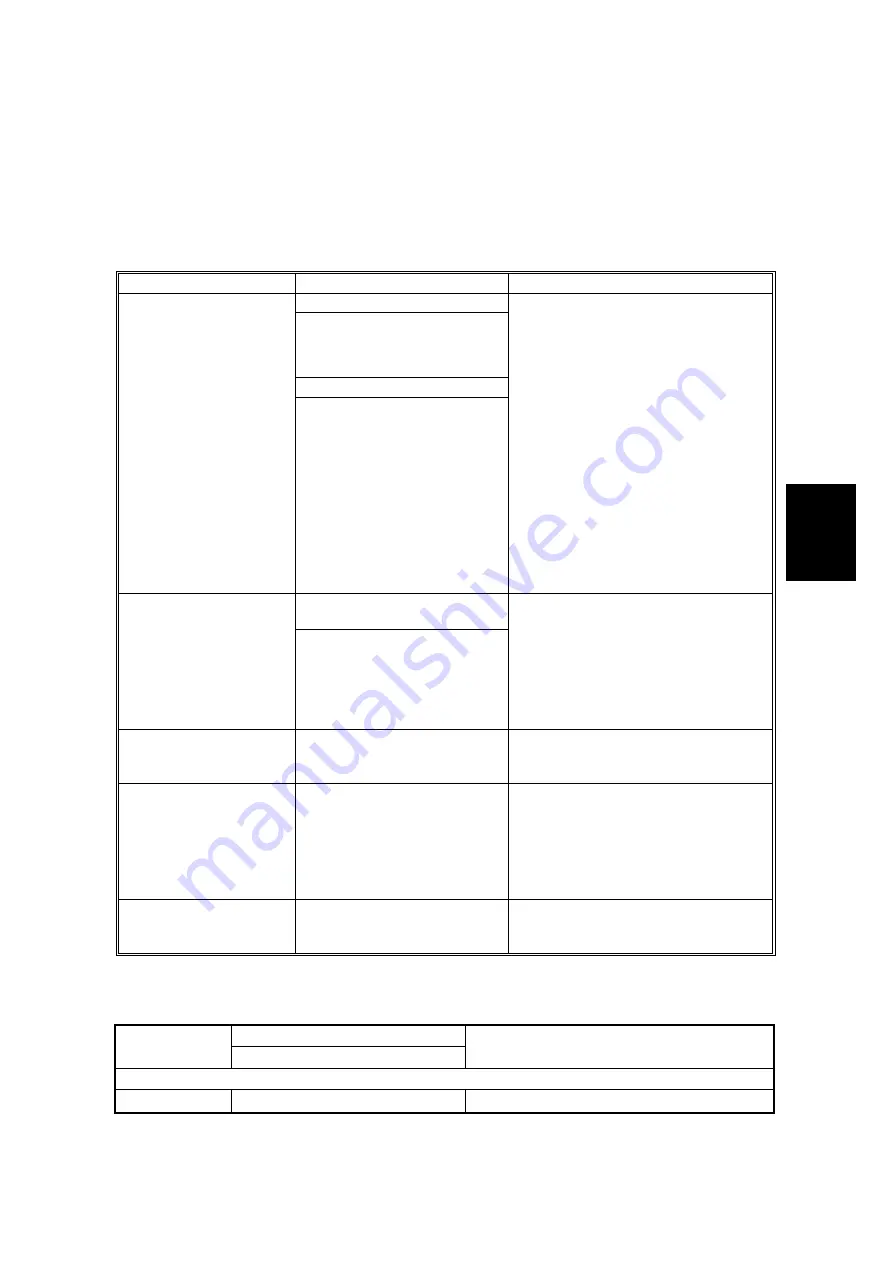

4.1.3 SELF DIAGNOSTIC MODE

This is done only when you turn on the main power of the machine. (

☛

4.1.1)

First turn off and on the main power when an error occurs. If an error remains after

doing that, do the actions in the column of “possible cause”.

Descriptions

Conditions Symptoms

Possible

cause

When turning on.

The HP sensor does not

detect the scanner optics

unit.

When scanning.

HP sensor error

The difference between the

scanner motor pulse in

scanning an original and

the one in returning to

home position is more than

15 mm.

•

Locked scanner optics unit

•

Defective HP sensor

•

Defective motor

•

Defective scanner timing belt

tension

•

Defective harness

1. Check the carriage lock switch.

(

☛

3.2.11)

2. Replace the HP sensor.

3. Replace the scanner optics unit

motor.

4. Check the scanner timing belt

tension.

5. Check or replace the harness.

Checking the ASIC for the

CCD is not done correctly..

CCD ASIC error

The DMA has no capacity for

storing the scanning data.

•

Defective FFC

•

Defective SBU

•

Defective CCD board

•

Defective MCB

1. Check or replace the FFC.

2. Replace the scanner optics unit.

3. Replace the MCB.

EEPROM error

The “BUSY” is flagged over

250 ms after writing to the

EEROM.

•

Defective MCB

1. Replace the MCB

Gain/ Offset adjustment

initialization error

The input level is less than

10 bit when doing the “Gain

adjustment”.

The input level is less than

10 bit when doing the “Off-

set adjustment”.

•

Defective exposure lamp

•

Defective SBU

•

Defective MCB

1. Replace the exposure lamp.

2. Replace the scanner optics unit.

3. Replace the MCB.

Memory error

A mismatching between the

scanning data and writing

data to the memory happens.

•

Defective MCB

1. Replace the MCB.

4.1.4 BLOWN FUSE CONDITIONS

Rating

Fuse

100-250 V

Symptom when turning on the main

switch

Power supply unit

FS1

2.5 A / 250 V

No response