Falk

™

Drive One

®

Enclosed Gear Drives

•

Owners Manual

Type D Series

•

Sizes M1130 thru M1210

(Page 9 of 27)

Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200

168-050

Telephone: 414-342-3131 Fax: 414-937-4359

January 2019

e-mail: [email protected] web: www.rexnord.com

Supersedes 04-11

(PN 2124650)

CAUTION: LUBRICANTS & INTERNAL BACKSTOPS

—

Do not use lubricants with anti-wear additives or lubricant

formulations including PTFE (Teflon), lead derivatives,

graphite or molybdenum disulfide in drives equipped with

backstops. Some lubricants in Table 8 may contain several

of these additives.

Synthetic Lubricants

Synthetic lubricants of the polyalphaolefin type are

recommended for cold climate operation, high temperature

applications, extended temperature range (all season)

operation, and/or extended lubricant change intervals. The

proper viscosity grade of synthetic lubricant is given in

Table 9. Refer to Table 10 for Synthetic lubricants.

WARNING: SYNTHETIC LUBRICANTS IN FOOD

PROCESSING INDUSTRY

— Synthetic lubricants may

contain toxic substances and should not be used in the food

processing industry without the lubricant manufacturers’

approval. Lubricants which meet USDA “H1” classification

are suitable for food processing applications.

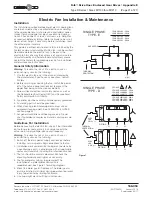

Bearing and Seal Greases

All drives and some backstops have grease-lubricated

seals. Some vertical shaft and specially mounted drives

have grease-lubricated bearings. Drives are shipped with

NLGI #2 grease in the seal housing cavities unless otherwise

specified. Refer to Table 11 for grease recommendations.

GREASE-LUBRICATED BEARINGS

— Vertical shaft

drives with drywells have grease-lubricated lower low-

speed bearings. These bearings are lubricated at the

Factory with an NLGI#2 grease. Refer to the preventive

maintenance instructions for greasing instructions.

GREASE-LUBRICATED SEALS

— Drive One drives are

furnished with grease purged seals which minimize the

entry of contaminants into the drive. Drives are shipped

with NLGI #2 grease in the seal housing cavities unless

otherwise specified. If grease could contaminate the

product, as in the food and drug industries, it should be

removed. A grease that meets USDA “H1” classification is

suitable for food processing applications.

Oil Levels

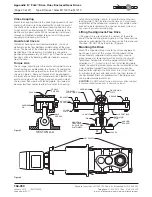

TYPES DH & DB

— Fill the drive with oil to the level

indicated on the oil dipstick. Approximate oil capacities are

given on the drive nameplate.

The inspection cover is sealed with a non hardening

chemical gasket eliminator. When replacing the inspection

cover, run a bead of Loctite 515 Gasket Eliminator

«

(or equivalent) around the perimeter of the inspection

opening, making sure to circle the fastener holes.

★

Product of Henkel Corp., Rocky Hill, CT.

DRIVES WITH OIL PUMPS

— Types DV, DX, and

occasionally other types of gear drives will be equipped

with oil pumps for cooling or special lubrication

considerations. If a drive is equipped with an oil pump,

fill the drive to the level marked on the dipstick. Run the

lubrication system for several minutes to fill the system

components. Verify that the pump is circulating oil properly,

then recheck oil level. If necessary, add oil to compensate

for filter and/or cooler.

Before starting the gear drive, rotate the input shaft to

check for obstructions. Then start the drive and allow it

to run without load for several minutes. Shut down and

recheck oil level. If everything is satisfactory, the drive is

ready for operation.

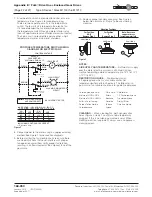

Preventive Maintenance

AFTER FIRST WEEK

— Check alignment of total system

and realign where necessary. Also tighten all external

bolts and plugs where necessary. DO NOT readjust the

internal gear or bearing settings in the drive. These were

permanently set at the Factory. See Table 12 for fastener

and wrench sizes.

AFTER FIRST MONTH

— Proceed as follows:

1. Operate drive until old sump oil reaches normal

operating temperature. Shut down drive and drain

immediately.

2. Immediately flush drive with an oil of the same type

and viscosity grade as the original charge (warmed to

approximately 38°C (100°F) in cold weather) by rapidly

pouring or pumping a charge equal to 25 - 100% of the

initial fill volume or until clean oil flows through the drain.

3. Close the drain and refill the drive to the correct level

with new oil of the correct type and viscosity.

PERIODICALLY

—

1. Check the oil level of the drive when it is stopped and at

ambient temperature. Add oil if needed. If the oil level is

ABOVE the high oil level mark on the dipstick, have the

oil analyzed for water content. Moisture in the oil may

indicate that a seal or the heat exchanger is leaking. If

so, replace the defective part immediately and change

the oil. DO NOT fill above the mark indicated as leakage

or undue heating may result.

2. Check coupling alignment to make certain that

foundation settling has not caused excessive

misalignment.

3. If drive is equipped with a fan, periodically clean

accumulated foreign matter from the fan, guard, and

deflector.

4. If drive is equipped with a torque arm, check for free

movement.

Table 11 — Greases for Bearings and Seals

–18° to +93°C (0° to 200°F)

Manufacturer

Lubricant

Amoco Oil Co.

BP Oil Co.

Chevron U.S.A., Inc.

Citgo Petroleum Corp.

Amolith Grease No. 2

Energrese LS–EP2

Industrial Grease Medium

Premium Lithium Grease No. 2

Conoco Inc.

Exxon Company, U.S.A.

E.F. Houghton & Co.

Imperial Oil Ltd.

EP Conolith Grease No. 2

Unirex N2

Cosmolube 2

Unirex N2L

Kendall Refining Co.

Keystone Div. Pennwalt Corp.

Lyondell Petrochemical (ARCO)

Mobil Oil Corp.

Mobil Oil Corp

Petro–Canada Products

Multi–Purpose Lithium Grease L421

Zeniplex 2

Litholine H EP 2 Grease

Mobilith 22

Mobilith SHC 460

«

Multipurpose EP2

Phillips 66 Co.

Shell Oil Co.

Shell Canada Limited

Sun Oil Co.

Texaco Lubricants

Philube Blue EP

Alvania Grease 2

Alvania Grease 2

Ultra Prestige EP2

Premium RB Grease

Unocal 76 (East & West)

Valvoline Oil Co.

Unoba EP2

Multilube Lithium EP Grease

★

High performance synthetic alternate.