Falk

™

Drive One

®

Enclosed Gear Drives

•

Appendix F

Type D Series

•

Sizes M1130 thru M1210

(Page 23 of 27)

Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200

168-050

Telephone: 414-342-3131 Fax: 414-937-4359

January 2019

e-mail: [email protected] web: www.rexnord.com

Supersedes 04-11

(PN 2124650)

Internal Cooling Tubes Installation & Maintenance

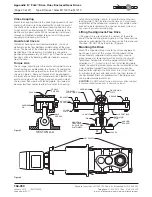

Cooling Tube Description

The internal cooling tube accessory is a network of finned

cooling tubes. Factory-installed in the base of a drive

housing, for heat removal. The cooling tubes operate

submerged in the oil of the drive sump. The revolving

elements provide the necessary oil flow around the

cooling tubes for efficient heat transfer. No oil pumps are

required. The external requirement for the cooling tube

system is a clean water hookup supplying a flow rate of 2

gallons (8 liters) per minute at a maximum temperature of

90°F (32°C). An inlet water temperature of 70°F (21°C) is

required to obtain the system catalog thermal power rating

with a sump oil temperature of 200°F (93°C).

The number of cooling tubes required varies with drive

size, type and number of reductions. Cooling tubes are

connected in series to maintain the optimum water flow

velocity in the tubes with the specified water flow rate of 2

to 5 gallons (8 to 19 liters) per minute. Note: A typical Falk

PC cooling assembly requires between 2 to 70 gallons (8

to 265 liters) of water per minute, depending upon PC size

and cooling requirements.

All cooling tube system connections are made outside of

the housing to eliminate the possibility of water leakage

into the drive sump. Seal rings are used at all connections

for ease of disassembly and reassembly. The standard

cooling tubes are 90/10 copper nickel alloy with aluminum

fins. Cooling tube connections are cadmium-plated mild

steel with “Buna-N” seal rings.

Water connections are .500”-14 NPT fittings located at

the high-speed end. The water outlet is located on the

high-speed end of the drive. The water inlet connection is

a straight fitting located on the lowest cooling tube in the

drive.

The water outlet connection is a right angle fitting (faced

up) located on the uppermost tube in the drive. The

cooling tube system connections are selected and located

so that the cooling system is always full of water during

operation for maximum heat transfer. The water inlet and

outlet connections may be moved to the opposite end of

the drive by removing the water inlet, outlet and all “loop

end” fitting assemblies and by reinstalling them on the

same tubes at the opposite end of the drive. Refer to the

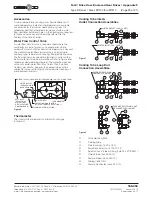

Maintenance Instructions on page 24 and Figures 7 & 8 on

page 25 for disassembly and reassembly.

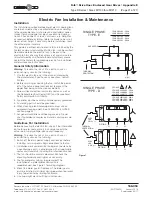

Installation & Operation

1. Connect the .500”-14 NPT straight water inlet fitting to

a source of clean, fresh water. Water must be regulated

to a minimum of 2 gallons (8 liters) per minute and must

not exceed 90°F (32°C).

2. Connect the .500”-14 NPT right angle water outlet fitting

(faced up) to an open drain. Do not pressurize the

cooling tube system. The turned up water outlet fitting

ensures that the system is always full of water during

operation.

3. Control water flow rate to between 2 and 5 gallons (8

and 19 liters) per minute to minimize fouling at low flow

rates or tube erosion at high flow rates. The water flow

rate may be reduced to 1 gallon (4 liters) per minute

if clean, fresh (drinking quality) water is used and the

sump oil temperature can be maintained within the

maximum limit of 200°F (93°C).

4. For shutdowns at ambient temperatures less than 32°F

(0°C), drain the cooling tube system by removing the

“loop end” assemblies on the end of the drive opposite

the water inlet. Refer to Figure 8 on page 25 for typical

assemblies and record location of assemblies for

reinstallation purposes.