Owners Manual

•

Falk

™

Drive One

®

Enclosed Gear Drives

(Page 10 of 27)

Type D Series

•

Sizes M1130 thru M1210

168-050

Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200

January 2019

Telephone: 414-342-3131 Fax: 414-937-4359

Supersedes 04-11

e-mail: [email protected] web: www.rexnord.com

(PN 2124650)

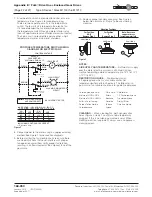

Lubricant Changes

OIL ANALYSIS REPORT

— Checking oil condition at

regular intervals is recommended. In the absence of more

specific limits, the guidelines listed below may be used to

indicate when to change oil:

1. Water content is greater than 500 ppm (0.05%).

2. Iron content exceeds 150 ppm.

3. Silicon (dust/dirt) exceeds 25 ppm.

4. Viscosity changes more than 15%.

PETROLEUM LUBRICANTS

— For normal operating

conditions, change gear oils every six months or 2500

operating hours, whichever occurs first. Change oil more

frequently when gear drives operate in extremely humid,

chemical or dust laden atmospheres. In these cases, R

& O and EP lubricants should be changed every 3 to 4

months or 1500 to 2000 hours. If the drive is operated in

an area where the temperatures vary with seasons, change

oil viscosity grade to suit temperature. Lubricant suppliers

can test oil periodically and recommend economical

change intervals.

SYNTHETIC LUBRICANTS

— Synthetic lube change

intervals can be extended to 8000 - 10,000 hours

depending upon operating temperatures and lubricant

contamination. Change oil more frequently when gear

drives operate in extremely humid, chemical or dust-laden

atmospheres. In these cases, synthetic lubricants should

be changed every 4 to 6 months or 4000 to 6000 hours.

Laboratory analysis is recommended for optimum lubricant

life and gear drive performance. Change lube with change

in ambient temperature, if required. Refer to Table 9 for

synthetic lubricant viscosity recommendations.

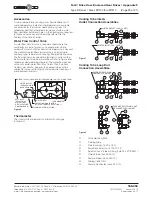

GREASE-LUBRICATED SEALS

— Depending on the

frequency and degree of contamination (at least every

six months or when changing oil in the drive), purge

contaminated grease from seals by slowly pumping fresh

grease, WITH A HAND GREASE GUN, through the seal

cavity until fresh grease flows out along the shaft. Wipe

off purged grease. Refer to Table 11 for NLGI #2 greases.

Some of these greases are of the IP type and may contain

toxic substances not allowed in the food processing

industry. A grease that meets the USDA “H1” classification

is suitable for food processing applications.

CAUTION

: Rapid greasing with a power grease gun can

force grease inward past the seals causing seal leaks.

GREASE LUBRICATED BEARINGS (TYPES DV AND DX)

— Most vertical low-speed shaft drives have a grease-

lubricated lower low-speed bearing. Grease bearings

during oil changes or at intervals of every 6 months or

2500 hours of operation whichever is less.

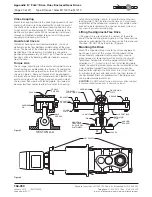

VERTICAL SHAFT DRIVES

— Remove the pressure relief

plug before greasing. Pump grease into bearing cage until

fresh grease appears at the plug. Replace the pressure

relief plug when finished. See figure below.

Refer to Table 11 for NLGI #2 greases. Some of these

greases are of the EP type and may contain toxic

substances not allowed in the food processing industry. A

grease that meets the USDA “H1” classification is suitable

for food processing applications.

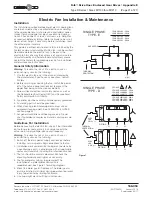

Table 12 — Fastener & Wrench Sizes

Fastener

DRIVE SIZE

M1130

M1140

M1150

M1160

M1170

M1180

M1190

M1200

M1210

Bushing

Nut

Diameter

185mm

7.3”

205mm

8.1”

225mm

8.9”

240mm

9.4”

260mm

10.2”

280mm

11.0”

295mm

11.6”

. . .

. . .

Circumference

581mm

22.9”

644mm

25.4”

709mm

27.9”

754mm

29.7”

817mm

32.2”

880mm

34.6”

927mm

36.5”

. . .

. . .

Bushing

Nut

Setscrew

Screw Size

M8

M8

M8

M8

M8

M8

M8

. . .

. . .

Hex Size

4mm

4mm

4mm

4mm

4mm

4mm

4mm

. . .

. . .

Inspection

Cover

Screw Size

M12

M12

M12

M12

M12

M12

M12

M12

M12

Wrench Size

19mm

19mm

19mm

19mm

19mm

19mm

19mm

19mm

19mm

Jackscrews

Screw Size

M12

M16

M16

M20

M20

M24

M24

M24

M24

Wrench Size

19mm

24mm

24mm

30mm

30mm

36mm

36mm

36mm

36mm

Magnetic

Drain Plugs

Plug Size

3/4 BSPT

3/4 BSPT

3/4 BSPT

3/4 BSPT

1.0 BSPT

1.0 BSPT

1.0 BSPT

1.0 BSPT

1.0 BSPT

Wrench Size

14mm

14mm

14mm

14mm

19mm

19mm

19mm

14mm

14mm

Other Plugs

Plug Size

3/4 BSPT

3/4 BSPT

3/4 BSPT

3/4 BSPT

1.0 BSPT

1.0 BSPT

1.0 BSPT

1.0 BSPT

1.0 BSPT

Hex Size

12mm

12mm

12mm

12mm

17mm

17mm

17mm

17mm

17mm

Torque

Arm

Nut Size

M30

M30

M36

M36

M36

M36

M48

M48

M48

Wrench Size

46mm

46mm

55mm

55mm

55mm

55mm

75mm

75mm

75mm

Grease

Purge

Cover

Screw Size

M6/M8

M6/M8

M6/M8

M6/M8

M6/M8

M8

M8

M8

M8

Wrench Size 10mm/13mm 10mm/13mm 10mm/13mm 10mm/13mm 10mm/13mm

13mm

13mm

13mm

13mm

Shaft Fan

Shroud

Screw Size

M8

M8

M8

M8

M8

M8

M8

M12

M12

Wrench Size

13mm

13mm

13mm

13mm

13mm

13mm

13mm

18mm

18mm

Shaft Fan

Setscrew

Screw Size

M6/M8

M6/M8

M6/M8

M8

M8

M8

M8

M10

M10

Hex Size

3mm/4mm

3mm/4mm

3mm/4mm

4mm

4mm

4mm

4mm

5mm

5mm

M

M

Q

Q

L

EE

CC

BEARING

GREASE

FITTING

RELIEF

PLUG