Appendix F

•

Falk

™

Drive One

®

Enclosed Gear Drives

(Page 24 of 27)

Type D Series

•

Sizes M1130 thru M1210

168-050

Rexnord Industries, LLC, 3001 W. Canal St., Milwaukee, WI 53208-4200

January 2019

Telephone: 414-342-3131 Fax: 414-937-4359

Supersedes 04-11

e-mail: [email protected] web: www.rexnord.com

(PN 2124650)

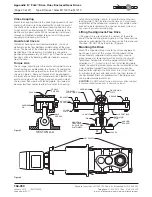

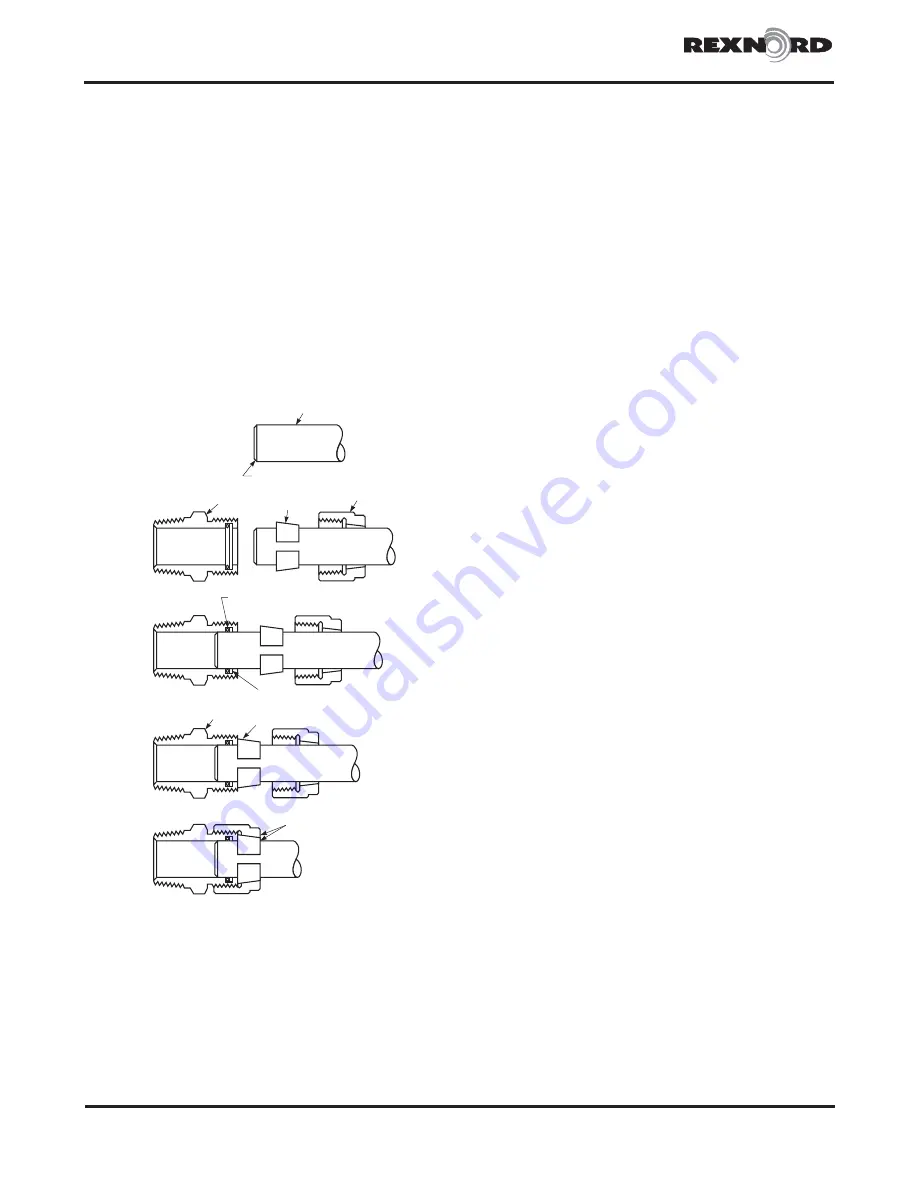

Assembly of Seal Ring Fittings

Note: For disassembly of seal ring fittings, reverse the

steps of the following assembly procedure.

1. Figure 1 — Deburr tube end to prevent cutting the

rubber seal ring during assembly.

2. Figure 2 — Slide nut and tapered split ring on tube. The

large end of the tapered split ring must face the fitting

body.

3. Figure 3 — Lubricate the rubber seal ring. Insert the

tube into the fitting body past the rubber seal ring.

4. Figure 4 — Slide the tapered split ring against the

fitting body. Lubricate O.D. of tapered split ring with #2

bearing grease.

5. Figure 5 — Assemble nut to fitting and tighten hand

tight. Turn nut with a wrench one turn or until the

tapered split ring is flush with the end of the nut.

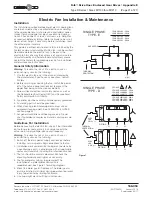

Maintenance Instructions

The cooling tube system is designed to be removed

from the drive housing without disturbing the drive or

its foundation, provided sufficient room is available at

either end of the housing for tube withdrawal. All tube

connections are outside the drive and are of the seal ring

type for ease of maintenance and reusability.

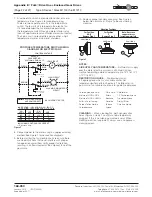

Light coatings of sludge or scale will cause a reduction in

heat transfer capacity of the system. Therefore, periodic

cleaning of the system may be required to restore the heat

transfer capacity.

The cooling tube system may be cleaned by flushing

with commercially available cleaning compounds

such as Oakite or Dowell. The commercially available

cleaning compounds are corrosive and must be used in

accordance with their manufacturer’s recommendations.

Cleaning may also be accomplished by means of a rod or

wire brush. Remove the tube end seal ring fittings (Figures

7 & 8 on page 25) and pass a .500” (12 mm) diameter rod

or wire brush through the tubes to remove the scale. Tube

I.D. is .527” (13.39 mm). After cleaning all tubes, reinstall

the tube end seal ring fittings.

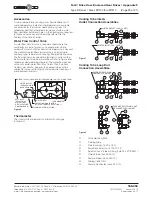

The outside of the cooling tubes (aluminum fins) may

be cleaned by removing the tubes from the housing and

cleaning with steam or a suitable solvent. To remove the

tubes from the housing, remove all seal ring fittings from

the tubes. Remove the 1.250-11 NPT x .750-14 NPT pipe

bushings from one end of the drive. A special deep well,

thin wall socket (1.812 hex by 7” deep) may be required to

remove and reinstall the pipe bushings.

CAUTION

: Take care not to damage cooling tube ends

during disassembly, cleaning and reassembly.

Withdraw the tubes from the housing through the 1.250-11

NPT holes using a .375” (10 mm) diameter rod through the

tube as a disassembly and reassembly aid. After cleaning,

reinstall the tubes in the drive. Coat pipe bushing threads

with thread sealant and reinstall the pipe bushings and

tube fittings in the reverse order of disassembly. Install

the loop end assemblies in the same positions as before

disassembly.

See left for seal ring fitting assembly procedures. Seal ring

fittings use standard No. 114 (.625 I.D. x .812 O.D. x .094

W) Buna-N seal rings if replacements are required.

TUBE

DEBURRED END

BODY

TAPERED

SPLIT RING

NUT

RUBBER SEAL RING

TEFLON BACK-UP RING

BODY

TAPERED SPLIT RING

TIGHTEN NUT

UNTIL FLUSH

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5