5

h. Adjust Filter, regulator, lubricator (Frl)

Note: It is imperative the filter, regulator, lubricator be

employed when running the UPC Pneumatic. The air

should be clean, dry, and lubricated to maximize motor

life and performance.

1. Before pressurizing, fill the oiler with the oil provided, by

removing the large black cap on the top. (Do not exceed

the maximum fill line) Replace cap.

2. Set air pressure to 90 PSI maximum. Loosen wing-nut

on bottom of regulator, and turn large knob clockwise

until pressure is attained.

3. Turn the small set screw to set the oil drip. The oiler

should be set of 5-8 drops per minute.

i. Fill and Attach Water tank (not required for

cutting plastic pipe) to blade Guard

Water is used to help cool the diamond blades when cut-

ting cast iron, ductile iron and clay pipe. In cold tempera-

tures, low-level heat may be applied to the water tank,

or a non-toxic, environmentally safe, anti-freeze may be

added to the water.

iv. OPErAtiOn

A. Position the Cutting blade

1. Loosen blade guard locking knob until swing guard

rests on pipe.

2. Turn cutter feed knob clockwise. (Fig.4) Lower motor and

cutter close to, but not touching the pipe. Motor bracket

locking knob should be tight, yet allow

the bracket to slide.

b. Pressurize Water tank by Following instructions

Provided with tank

Open valve on tank. Continue to repressurize tank dur-

ing use.

Special instructions

for cutting Steel Pipe and PE Pipe on next page.

C. turn Motor On

After ensuring air line is clear of dirt and debris, connect

air hose to motor. Open ball valve on motor.

WArninG: blade is now rotating, keep hands clear.

d. slowly Feed the blade into the Pipe.

Note: Fast feeding can result in tracking off.

1. Note position of depth gauge pointer (divided in tenths

of inches with MM references). (Photo #3)

2.* Knowing the thickness of pipe to be cut, turn the feed

knob clockwise, (Fig. 4) until the pointer indicates

the desired depth of cutter. Allow at least

1

/

4

" of blade

beyond depth of cut.

*Exception to this would be if the bevel cutter was being

used for plastic, then the cutter would be engaged until

the bevel cutter began cutting. At this point the depth

gage pointer could be used to determine amount of

bevel. Full engagement produces a

15

/

16

" bevel. (Fig. 4)

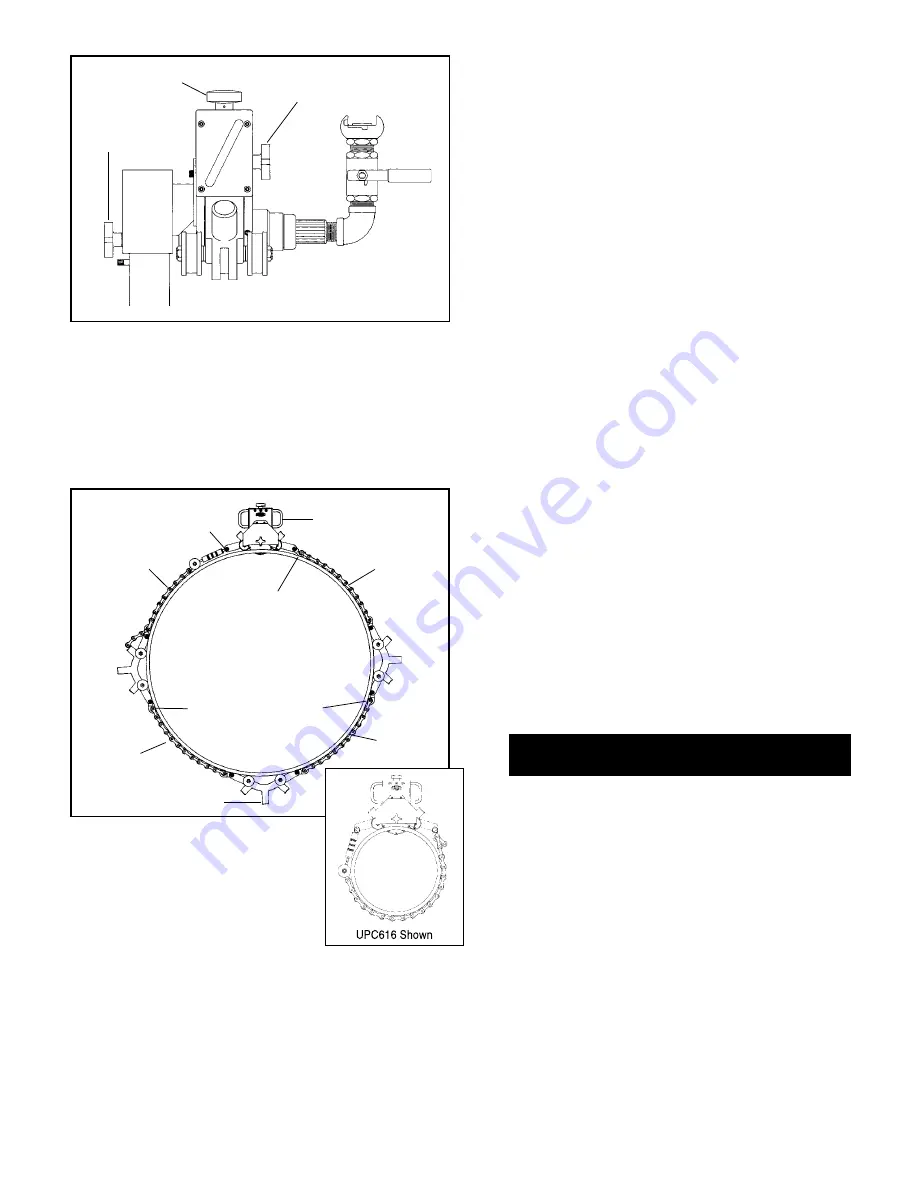

FIG. 5

F. Align Cutter (test tracking)

Rotate unit around pipe (one

revolution). To check tracking ac-

curacy, mark the pipe at one of the

motor unit rollers and rotate the

unit again and note off/on track condition. By tapping or

resetting the chain and/or connecting frames, the unit

can be aligned.

G. Connect Air supply

Unit is supplied with Street Ell, Ball valve and Dixon

coupling, however, any combination of piping to the unit

can be used as long as all fittings are full flow to ensure

maximum motor RPM. Always connect to warm air side

of compressor if so equipped. This will provide best tool

performance.

Connecting Frame

Motor Unit

release Pin

11 link

Chain

13 link

Chain

Chain hook (down)

Chain hook (Up)

UPC648

36" - 48" size shown

Motor bracket

locking Knob

Feed Knob

blade Guard

locking Knob

FIG. 4

6. If cutting pipe where connecting frames and 11 link

chains are needed, (UPC636 & UPC648) pre-assemble

chain hooks to the aluminum connecting frames, with

the chain hooks in the downward position. Return to

Step 5, being sure to space the connecting frames

equidistant to the motor unit. (Fig. 5)

11 link

Chain

11 link

Chain

Содержание UPC616A

Страница 35: ...35...