US FLOOR / FLOOR

Minichiller inverter Duo

31

•

Check that the heating elements of the compressor are powered properly.

•

Ensure that there are no gas leaks.

•

Before the start up, check that all shutting panels are positioned and fixed with proper screws.

WARNING: The unit must be connected to the electrical network and should be adjusted in STAND-BY mode

(powered) turning on the general switch for a minimum of 12 hours before start up in order to operate the crankcase

heaters of the compressor, for allowing the proper heat to the compressor crankcase (the heaters are automatically

electrified when the switch is closed).The crankcase heaters turns on properly if after some minutes the temperature

of crankcase’s compressor is about 10°C ÷ 15°C higher than ambient temperature.

WARNING: Never switch off the unit (for a temporary stop) by the way of the main switch, this last component

should be used to disconnect the unit from the power supply only for lengthy stoppages (e.g. seasonal stoppages).

Besides, failing the power supply, the crankcase’s resistances are not supplied thus resulting in a possible breakdown

of the compressors once the unit is switched on.

WARNING: Do not modify the internal wiring of the unit otherwise the warranty will terminate immediately.

WARNING: The summer/winter operating mode has to be selected at the beginning of the related season. Frequent

and sudden changes of this operation should be avoided in order to prevent severe damages to compressors.

WARNING: For the first installation and start-up of the unit, make sure that the unit is working correctly in both

cooling and heating modes.

11

INDICATIONS FOR THE USER

Write down the identification data of the unit for to provide them to the service center in the event of a request for assistance.

The identification label of the machine reports the technical data and performance of the equipment.

In case of lost or damage identification label, ask a duplicate to a Technical Service Center.

Tampering with, removal, deterioration of identification label, makes difficult any operation of installation,

maintenance and demand for spare parts.

It is advisable to keep track of the work performed on the unit, so any troubleshooting will be easy to find.

In case of failure or malfunction:

•

check the type of alarm to indicate to the service center;

•

contact an authorized service center;

•

if required by the service center, turn off the unit immediately without resetting the alarm;

•

require the use of original spare parts.

12

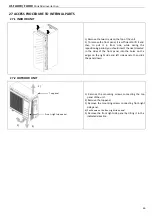

SHUTDOWNS FOR LONG PERIODS

•

Turn off the units from control panel (displayed “OFF”).

•

Close the water tap.

•

Place the general differential QF switch in “OFF” state.

If the indoor unit is installed in areas of the building subject to low temperatures (attics, basements, etc.) and the

temperature drops below 0°C there is serious danger of frost: provide please a mixture of water and glycol in the

plant system, otherwise drain the water system and the hydraulic circuits of the heat pump.

If it is necessary to add glycol to the hydraulic circuit of the plant, provide a T-fitting with tap downstream of the

non-return valve on the charging/topping-up pipe (see Paragraph 7.5), in order to adapt the glycol concentration.

WARNING: the operation, although it was transient, with water temperatures below +5°C is not guaranteed on the

basis of the limits set out in Paragraph 24.4 . Before you turn the unit on after a long off period, make sure that the

temperature of the mixture of water and glycol is higher than or at least equal to +5°C.

13

MAINTENANCE AND PERIODIC CHECKS

WARNING: All the operations described in this chapter HAVE TO BE CARRIED OUT BY TRAINED STAFF ONLY. Before

any operation or before acceding to the inner components of the unit, be sure that the power supply is not

connected. The compressor’s heads and discharge piping are usually at high temperature levels. Be very careful when

operating in their surroundings. Aluminum coil fins are very sharp and can cause serious wounds. Be very careful

when operating near them. After servicing operations, re-install the cover panels, and fix them by means of screws.

The refrigerant circuits must not be filled with refrigerant gas other than that indicated on the nameplate. The use

of a different refrigerant can cause severe damage to the compressor.

It is forbidden to use refrigerant oils other than those specified in this manual. The use of different oil can cause

serious damage to the compressor.

The top part and discharge pipes of the compressor operating at high temperatures. Be sure to let the unit to

become cool before beginning any maintenance work.

Содержание FLOOR-S

Страница 2: ......

Страница 57: ......

Страница 58: ......

Страница 59: ......

Страница 60: ...9120488 02 12 2016 bit ly rdzwebsite ...