US FLOOR / FLOOR

Minichiller inverter Duo

22

7.6

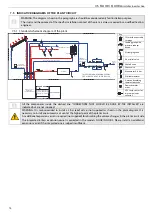

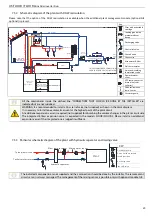

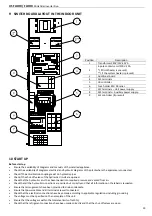

REFRIGERANT CONNECTIONS

The refrigerant connections are equipped with shut off valves on the outdoor unit and designed for flare connections.

How to make the connection:

•

Place the refrigerant pipes; (place the refrigerant pipes, the number of curves should be as low as possible and avoid

throttling of the pipes)

•

bring together the flared ends to their connection located on the indoor and outdoor units;

•

tighten the connections by using the method of ”key against key”;

•

perform a proper evacuation of the refrigerant pipes

using the taps of the moto-condensing unit (similar system to

household split)

•

check if the work is being done well by evaluating the rise time by mean of pressure gauge that integrated in the vacuum

pump.

•

release the refrigerant contained in the moto-condensing unit by opening the gas/liquid valves (see Paragraph 7.4.2.2)

•

add or take out a proper amount of refrigerant as indicated in the paragraph 15.2 see note (5).

•

check if there is no refrigerant leakage;

•

cover the connections with insulating material.

Do not put both pipes in the same protecting sheath, in order to ensure the correct operation of the plant.

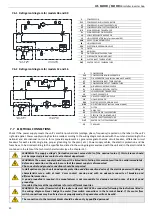

Mod 06 09 12 16

Liquid pipe diameter (

Ø)

mm

6,35 9,53 9,53 9,53

Gas pipe diameter (

Ø

) mm

12,7 15,9 15,9 15,9

A

Max length of piping

m

25 30 30 30

B

Max difference level

m

15 15 20 20

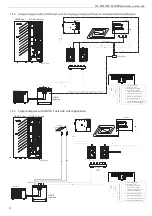

Do not carry out the connections by using ordinary hydraulic pipes that might contain inside themselves residues of

chips, dirt, or water which can damage the components of the unit and alterate the correct operation of the

equipment.

Use only specific refrigeration copper pipes that should be provided clean and sealed at the ends.

Use only pipes with correct dimensions of diameters; refer to the table of the technical data in the chapter 15.

Cut the pipes with wheel pipes cutter, clutch slowly paying attention for not to crush the pipes when using the tool.

Never use an ordinary hacksaw because shavings could go into the pipe and then circulate in the system which can

seriously damage the components.

After cutting the pipe, please seal immediately the opening on both ends of the roll and cut pipe.

The equipment does not require any additional refrigerant.

The refrigerant pipes should be straight as possible and the necessary bends must have radius more than 300mm.

Plug the opening on the ends of the pipes before inserting them through the hole in the wall.

The refrigerant piping and joints must be thermally insulated to prevent heat loses.

You should avoid the introduction of non-condensable gases (air) into the circuit; otherwise, the pressure becomes

high during operation with the risk of system breaking.

A FITTING KIT PROVIDED WITH THE INDOOR UNIT IS REQUIRED FOR THE CONNECTION OF THE INDOOR UNIT 06

WITH OUTDOOR UNIT 06.

Содержание FLOOR-S

Страница 2: ......

Страница 57: ......

Страница 58: ......

Страница 59: ......

Страница 60: ...9120488 02 12 2016 bit ly rdzwebsite ...